Enhancing Heat Resistant Stainless Steel with Rare Earth Alloys

Stainless steel is strong, but it has trouble in very high temperatures. When it gets too hot, the steel reacts with oxygen in the air. This makes a thin layer on the surface that can…

Please Fill the form

we'll connect you within hours

Stainless steel is strong, but it has trouble in very high temperatures. When it gets too hot, the steel reacts with oxygen in the air. This makes a thin layer on the surface that can…

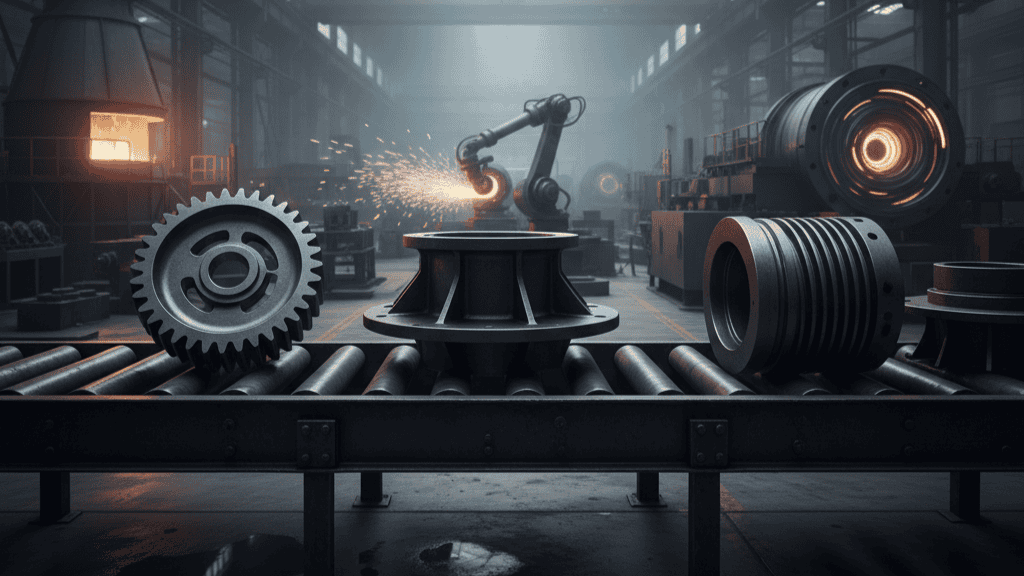

Heat resistant casting is used to make metal parts that must work in very hot places. These places can be furnaces, ovens, kilns, and power plants. In these places, normal metal can melt, bend, or…

Aluminum die casting is a way to make strong and useful metal parts. In this process, hot liquid aluminum is poured or pushed into a special mold called a die. The die has a shape…

Ever wondered how modern machinery or bridges handle all stress without cracking? Moreover, what’s the base material that they don’t even catch rust over time? The answer often lies in a single material, low-alloy steel.…

Manganese steel is a very strong metal. It contains iron, carbon, and manganese. Robert Hadfield discovered it in 1882, and people now call it Hadfield steel in his honor. This steel hardens when something hits…

Gone are the days when manual tools could keep up with today’s precision demands. Today, manufacturers use hydraulic CNC press brakes – advanced sheet metal bending machines known for their accuracy and efficiency. This technology…

A stainless steel casting crucible is a container that holds and melts metal. Foundries use it when making parts. It must stand up to very high heat. Crucibles matter because they keep melted metal clean.…

Making strong parts is important in many industries. Machines need grooves, slots, and smooth 3D shapes to work. Gantry CNC milling machines can cut both simple and complex parts. They do this with high precision.…

High-speed and high-precision are the new manufacturing environment. And laser machining is setting new standards for accuracy, repeatability, and efficiency. From micro-drilled holes in medical devices to precision cuts in aerospace turbine blades, laser positioning…

Precision CNC machined parts are parts made with great care and accuracy. These parts are used in many things like airplanes, cars, and hospital tools. The machines that make them follow computer instructions to cut,…

The Need for Precision in Modern Manufacturing Modern machines need parts that fit just right. Even a small error can cause big problems. It can break the product or make it unsafe. That is why precision machined parts are…

CNC machining technology has revolutionized how electric bike (ebike) components are designed, produced, and assembled. As ebike designs push for higher performance, lighter materials, and modular construction, CNC machining offers the precision, scalability, and consistency…

Do you want liners that last longer and work better? This guide to the alloy steel liner manufacturing process will help you understand how they are made. Alloy steel liners are strong. They can handle…

In modern manufacturing, industrial casting methods play a vital role in shaping the backbone of industries from aerospace to automotive. Each casting technique offers distinct advantages in material use, design precision, cost, and production scale.…

Cars have many metal parts, and casting helps shape them. This process is used to make things like engine blocks, wheels, and gear cases. It helps build cars that are strong, light, and not too…

Do you want liners that last longer and work better? This guide to the alloy steel liner manufacturing process will help you understand how they are made. Alloy steel liners are strong. They can handle…

Speed, flexibility, and cost-efficiency are more critical in today’s manufacturing landscape than ever. Whether you are prototyping a new part or running a short production cycle, aluminum molds have emerged as a game changing solution.…

Water glass sand casting, also called the sodium silicate process, is a popular way to make metal parts. It uses sodium silicate to form strong molds. These molds can handle high heat and hold their…

You want strong, fast, and affordable molds for your plastic parts. Aluminum molds can help you do this. They are metal molds made from aluminum instead of steel. Today, many engineers and product designers choose…

Traditional core limitations are holding back your designs. If you have ever struggled to create internal features in complex parts, you know that conventional cores can quickly become the bottleneck. That is where soluble cores…

Traditional cores can’t make the shapes you want inside your parts. They can’t create small or tricky spaces. Soluble cores can fix this problem. You can use soluble cores in metal casting, injection molding, or…

When industries need a material that’s strong, light, affordable, and resistant to corrosion, aluminum often comes out on top. Its lightweight nature, combined with impressive strength, corrosion resistance, and affordability, makes it a go to…

Metal parts get dirty. Rust, paint, and oil can stick tight. Factories must clean these parts before they build, weld, or paint them again. Two big ways to do this are laser cleaning and sandblasting.…

In manufacturing, getting the part size and weight is very important. If a part is too big or too heavy, it might not fit, work right, or be safe to use. It can also cost…