Mold development

Molds are designed per drawings: lost foam for small runs, plastic or metal molds for large-scale production.

Please Fill the form

we'll connect you within hours

The company mainly produces various wear-resistant and heat-resistant components for building materials, mining, and power equipment.

It is equipped with testing instruments such as spectrometers to ensure quality control throughout the entire production process.

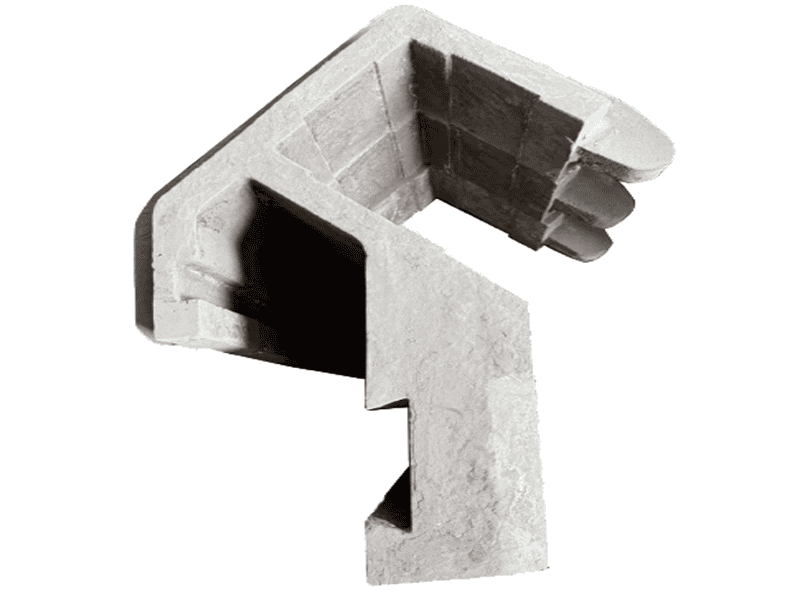

Customer-ordered gating cups are cast using the coated sand process, formed through core shooting and curing.

Lean More >>

Customer-ordered hammer heads are cast with coated sand and heat-treated for hardness and wear resistance.

Lean More >>

Custom rake teeth manufactured using the sand casting process, delivering durability and reliable performance.

Lean More>>

Custom gear sleeves manufactured using the sand casting process to ensure high precision and reliable performance.

Lean More >>

Custom heat-treatment baskets manufactured using sand casting, offering excellent heat resistance and structural strength.

Lean More >>

Custom furnace pots manufactured using the lost foam casting process, ensuring excellent heat resistance and dimensional accuracy.

Lean More >>

Leverage our extensive network and discover the possibilities Huashun can offer you

Each project follows a well-established cooperation process. Professional staff provide 24/7 tracking services, ensuring efficient communication and rapid quotation.

Molds are designed per drawings: lost foam for small runs, plastic or metal molds for large-scale production.

Molds are designed per drawings: lost foam for small runs, plastic or metal molds for large-scale production.

Alloy materials are melted in suitable furnaces, with chemical composition and temperature controlled to meet specifications.

Qualified molten metal is poured into the sand mold under strict safety and process controls.

After pouring and solidification, the sand is removed, gates and attachments are cut off, forming the casting; machining ensures proper assembly.

All castings are inspected with CMM, chemical composition checked via spectrometer, hardness tested with Brinell or Leeb testers, and tensile reports provided if required.

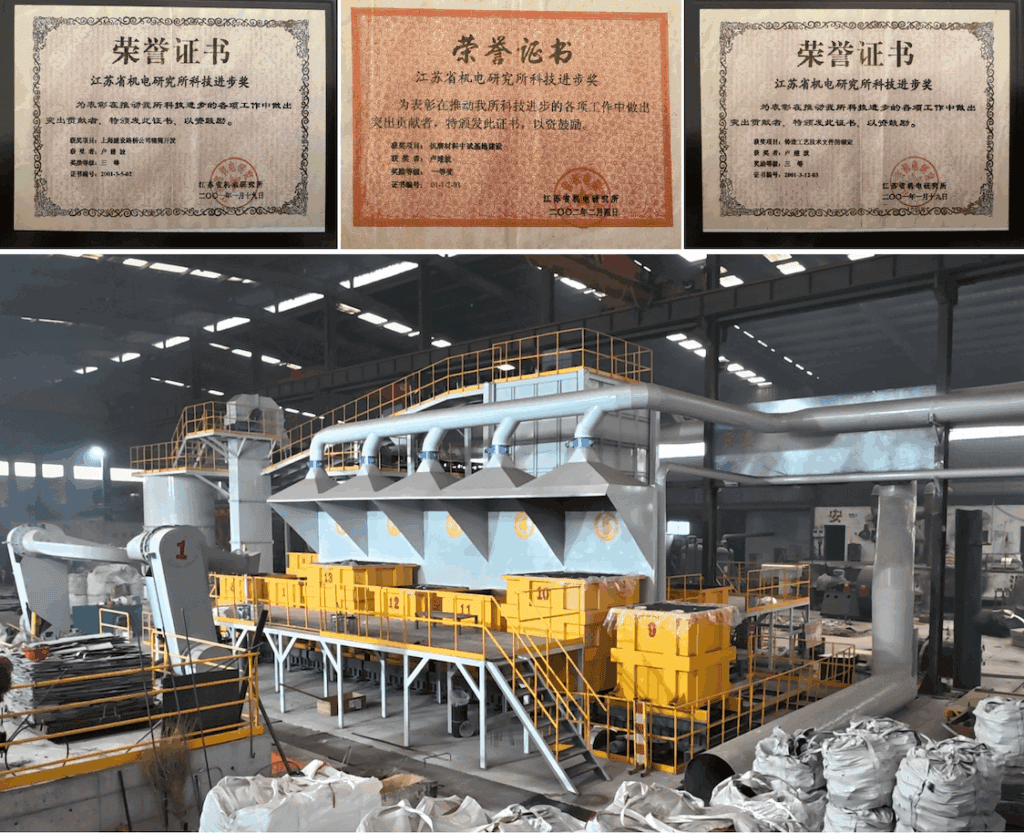

A casting company with 30 years of expertise in wear-resistant and heat-resistant cast components, helping customers save up to 30% in costs.

Nearly 30 years of experience in wear-resistant and heat-resistant cast components, delivering cost-effective material solutions for mining and crusher equipment.

Advanced testing equipment ensures strict quality control and consistent, reliable performance from casting to finished products.

Integrated casting and precision machining services, supported by in-house CNC equipment and strategic cooperation with XCMG.

Discover what our clients have to say

Explore the Latest Trends, Technologies, and Benefits in the World of Casting and Forging for Industrial Excellence

Aluminum die casting is a way to make strong and useful metal parts. In this process, hot liquid aluminum is poured or pushed into a

Ever wondered how modern machinery or bridges handle all stress without cracking? Moreover, what's the base material that they don't even catch rust over time?

Manganese steel is a very strong metal. It contains iron, carbon, and manganese. Robert Hadfield discovered it in 1882, and people now call it Hadfield

Your Questions Answered: Everything You Need to Know About Our Services

Yes, we offer custom casting solutions based on customer drawings and real operating conditions, ensuring optimal material selection for durability and cost-efficiency.

We use advanced tools, including German spectrometers and coordinate measuring machines, for comprehensive quality inspections.

We implement full-process quality control using advanced equipment such as spectrometers, temperature testers, metallographic analyzers, and hardness testers to guarantee stable performance from raw materials to finished products.

Absolutely. Our in-house CNC machining centers, milling machines, large gantry machines, and drilling equipment allow us to provide one-stop casting and precision machining solutions, ensuring efficient and reliable delivery.

If possible, we request you provide us with the following information to provide our offer:√2D drawings with dimension tolerances and/or 3D models The desired grade of the metals and alloys