Aluminum die casting is a way to make strong and useful metal parts. In this process, hot liquid aluminum is poured or pushed into a special mold called a die. The die has a shape inside it. When the aluminum cools and becomes solid, it comes out in the same shape as the mold.

People use aluminum for many products because it is light, does not rust easily, and is very flexible. Aluminum die casting helps factories make parts that have a lot of detail and fit together very well. This is important for cars, airplanes, machines, and many things we use every day.

Today, aluminum die casting helps many industries create parts that are strong, smooth, and ready to use. That is why it is one of the most helpful ways to make metal parts.

What Is Aluminum Casting Die

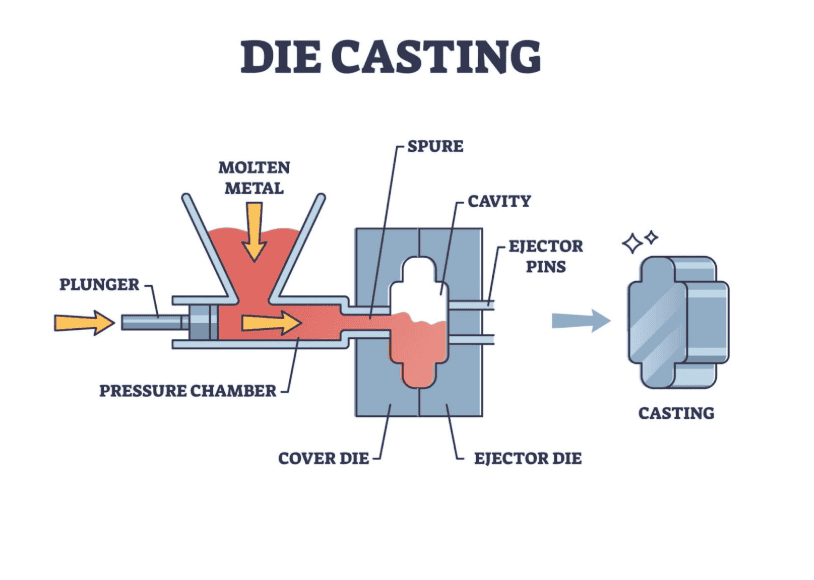

Die casting is one of the oldest methods used to shape metals. The metal or metal alloy is melted, then poured into a prepared mold and allowed to cool. The molded piece is then removed from the mold and processed further by one or more of a great variety of processes.

Aluminum die casting refers to the process of producing metal components by injecting molten aluminum into molds at high pressure, which allows for high production rates and good dimensional repeatability, particularly in the automotive and mechanical engineering sectors.

The Aluminum Die Casting Process

Aluminum die casting is a step by step process. Each step is important to make a strong and correct part.

Step 1: Making the Die (The Metal Mold)

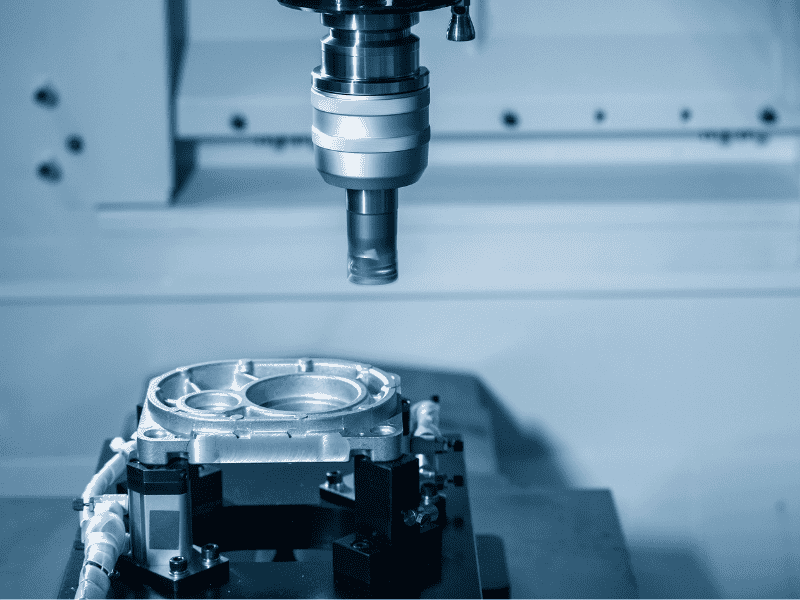

The first step is to make the die. A die is a very strong metal mold. It is usually made from hard steel.

- The die is designed on a computer.

- Then machines cut the steel to make the inside shape.

- The inside of the die is the exact shape of the part we want.

The die is made in at least two halves. This helps the part come out later. Some dies also have moving parts, like slides or cores. These help make holes, deep pockets, or special shapes in the part.

Making the die takes time and money, but it can be used many times to make thousands of parts.

Step 2: Clamping the Die

The two halves of the die are put into a die casting machine. The machine closes the halves together very tightly. This is called clamping.

Clamping is important because:

- It keeps the two halves in the right place.

- It stops the hot aluminum from leaking out.

- It helps the part keep the right size and shape.

The machine uses very strong force to hold the die shut during casting.

Step 3: Melting the Aluminum

Before the aluminum can go into the die, it must be melted.

- Solid aluminum is heated in a furnace.

- It is heated until it turns into a liquid.

- The liquid aluminum looks like shiny, glowing metal.

The temperature must be just right. If it is too cold, the metal will not fill the mold. If it is too hot, it can damage the die or cause problems in the part.

Step 4: Injecting the Molten Aluminum

Now the liquid aluminum goes into the die.

- The machine pushes the molten aluminum into the die very fast.

- It uses high pressure to force the metal into every small space.

This pressure is very strong. It helps the metal reach thin walls, tiny corners, and fine details.

Because of this step, die cast parts can have:

- Smooth surfaces

- Thin walls

- Very exact shapes

Step 5: Cooling and Solidifying

After the aluminum fills the die, it must cool.

- The metal touches the cold steel walls of the die.

- Heat leaves the aluminum and goes into the die.

- The aluminum gets cooler and turns solid.

This step is called solidifying. The part must stay inside the die until it is hard enough to keep its shape.

Some dies have cooling channels with water or oil inside. This helps control how fast the part cools. Good cooling makes the part stronger and helps avoid defects.

Step 6: Opening the Die

When the part is solid, the machine opens the die.

- The two halves move apart.

- You can now see the new aluminum part inside.

The part is still attached to extra metal, called the runner and gates. These are the paths the metal used to enter the cavity. They will be removed later.

Step 7: Ejecting the Casting

The part is pushed out of the die.

- The die has pins inside called ejector pins.

- When the die opens, these pins push the part out gently.

The pins must push in the right spots. If not, the part can bend, crack, or get stuck. Good design of the ejector pins helps protect the part and speeds up production.

Step 8: Trimming and Cleaning

After the part comes out, it still has extra metal around it.

- The extra metal from runners and gates is cut off.

- Sharp edges are removed.

- The surface may be cleaned or gently smoothed.

Sometimes, parts go through a deburring step. This removes small bumps and rough spots. Now the part looks closer to its final shape.

Step 9: Surface Finishing (If Needed)

Many die cast parts already have a good surface. Sometimes, companies still add a finish to make them stronger or nicer.

Common finishes include:

- Painting

- Powder coating

- Anodizing

- Polishing

These finishes can:

- Protect the part from rust and damage

- Make it look more attractive

- Match company colors or branding

Step 10: Quality Check and Use

The last step is to check the part.

- Workers or machines measure key sizes.

- They look for cracks, holes, or other problems.

- Only good parts are packed and shipped.

After that, the parts go to car makers, machine makers, or other factories. There, the parts are used in bigger products like cars, bikes, tools, or devices.

Advantages of Using Aluminum Die Casting

Aluminum alloys are desirable in many applications because of their high strength to weight ratio and corrosion resistance. This is particularly true in transport applications and in pressure systems where the strength of materials is often purposefully kept low.

Lightweight and Strong

Aluminum is a lightweight and strong material that is highly valued in various industries. Aluminum die casting allows for the production of lightweight parts with high strength-to-weight ratios. This makes aluminum die casting an ideal choice for manufacturing parts that require both strength and weight savings.

Does Not Rust Easily

Aluminum does not rust the way iron does. This helps the parts stay clean and safe, even when they are outside or near water. It also means the parts last longer.

Good at Moving Heat and Electricity

Aluminum can move heat and electricity well. This makes it good for parts in electronics, motors, and lights. It helps keep machines cool and working safely.

Makes Smooth and Exact Parts

Die casting makes parts that are very smooth and the right shape. The mold helps every part look the same. This is important when thousands of parts need to fit together in big machines.

Fast for Large Production

Die casting is a fast process. Once the mold is ready, the machine can make many parts in a short time. This helps companies save time and money.

Low Cost for Big Orders

The mold costs money to make, but after that, each part is cheap to produce. This is helpful when a company needs many parts for cars, tools, or machines.

Strong and Even Walls

Aluminum die casting produces parts that are highly durable and resistant to corrosion, making them ideal for use in harsh environments or applications where parts are subjected to high stress or wear.

Types of Aluminum Die Casting Processes

There are a few main ways to do aluminum die casting. Each way has its own purpose. Factories pick the one that works best for the part they want to make.

High-Pressure Die Casting

This is the most common method.

In this process:

- Melted aluminum is pushed into the mold very fast.

- A strong machine uses high pressure to fill every small space.

- The part cools quickly and becomes solid.

High pressure die casting is good for:

- Making many parts fast

- Making small and medium parts

- Making parts with smooth surfaces

Some factories use vacuum help in this method. This removes air from the mold and makes the part stronger with fewer tiny holes inside.

Low-Pressure Die Casting

This method works slower than high pressure casting.

In this process:

- Melted aluminum rises into the mold from below.

- Gentle pressure is used, not strong pressure.

- The part cools slowly.

Low pressure die casting is good for:

- Parts that need better strength

- Parts that need to be very clean inside

- Parts that must not have many air bubbles

It takes more time, but the parts usually have better quality.

Gravity Die Casting

Gravity die casting uses simple gravity to fill the mold.

In this process:

- Melted aluminum is poured into the mold by hand or by a machine.

- The metal flows down into the mold because of gravity.

- The part cools inside the mold.

Gravity die casting is good for:

- Parts with thick walls

- Parts that need good strength

- Parts that do not need very thin or tiny shapes

This method is slower, but it makes strong and reliable parts.

Cold Chamber Die Casting

Cold chamber casting is used for metals like aluminum that melt at high heat.

In this process:

- The metal is melted in a separate furnace.

- A ladle moves the hot aluminum into the casting machine.

- Then the metal is pushed into the mold.

Common Aluminum Alloys Used in Die Casting

Aluminum alloys are special mixes of aluminum and other elements. These mixes help the metal become stronger, smoother, or easier to cast. Different alloys are used for different jobs.

Alloy 380

Alloy 380 is the most popular alloy in aluminum die casting.

It is used because:

- It is easy to cast

- It fills the mold well

- It has good strength

- It does not rust easily

Many companies use Alloy 380 for car parts, tools, and machine parts.

Alloy A360

A360 is another common alloy.

It is known for:

- Very good strength

- Very good corrosion resistance

- Better flow into the mold than 380

Alloy A383

A383 has more silicon in it. Silicon helps the metal flow smoothly into thin or tricky parts of the mold.

A383 is good for:

- Small thin parts

- Parts with tiny details

- Parts that need great castability

Alloy 360

Alloy 360 is used for parts that face high heat.

It is known for:

- Strong performance when hot

- High corrosion resistance

- Good durability

Properties and Applications of Aluminum Die Cast Parts

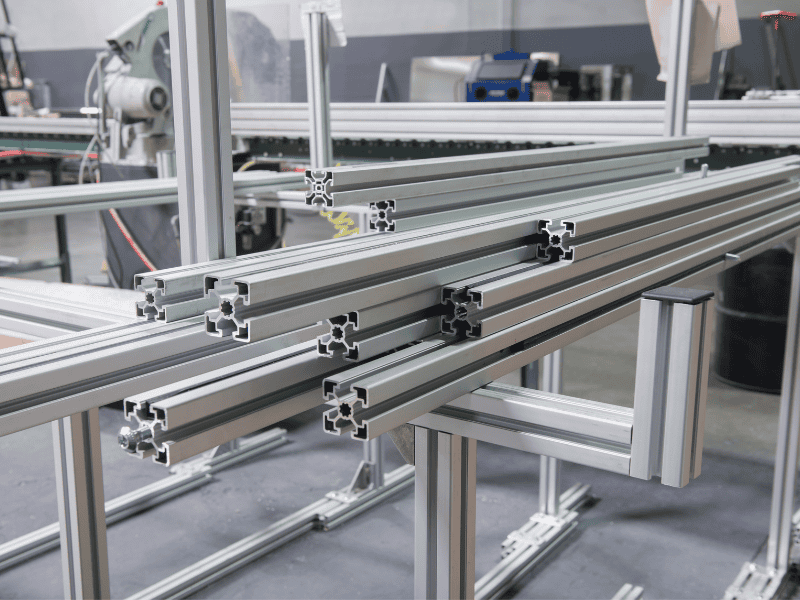

Aluminum die cast parts are used in many places because they are light, strong, and easy to shape. These parts help build machines, vehicles, tools, and many products we use every day.

Easy to Shape into Complex Designs

Aluminum die casting can make parts with tiny details and special shapes. The metal flows into every small space in the mold, so the part comes out neat and exact.

- Fit together perfectly

- Have smooth surfaces

- Have small or tricky shapes

Strong and Long Lasting

Even though aluminum is light, it is still very strong. The parts can handle pressure, heat, and daily use. This is why many industries trust aluminum die cast parts.

Used in Cars and Trucks

The car industry uses many aluminum die cast parts.

Common parts include:

- Engine covers

- Transmission parts

- Brackets and mounts

- Light housings

Used in Aerospace

Airplanes and space equipment need light but strong parts. Aluminum die cast parts are perfect for this. They can handle high heat, heavy use, and tough weather.

Used in Electronics and Telecommunications

Because aluminum moves heat well, it is used in:

- Phone parts

- Computer parts

- Cooling housings

- Signal boxes

Used in Renewable Energy

Wind turbines and solar systems use aluminum parts because they are light and do not rust. This helps the equipment last longer outside in sun, rain, and wind.

Used in Medical Devices

Medical tools and machines need clean, safe, and strong parts. Aluminum castings help make frames, covers, and small pieces inside the machines.

Used in Agriculture and Military

Farm tools, tractors, and other equipment use aluminum parts because they are strong and reliable. The military uses aluminum parts in gear and tools because they are light and tough.

Comparison With Other Casting Methods

Aluminum die casting is one way to make metal parts, but it is not the only way. Other methods include sand casting and permanent mold casting. Each method has its own strengths and limits.

Die Casting vs Sand Casting

Sand casting uses sand to make the mold.

Sand casting is good for:

- Very large parts

- Small or large orders

- Lower mold cost

But sand casting has limits:

- The surface is rough

- The sizes are not as exact

- Parts may need more finishing

- It takes more time

Die Casting vs Permanent Mold Casting

Permanent mold casting also uses a metal mold, but without high pressure.

- Medium sized parts

- Strong parts with good thickness

- Lower cost than die casting tools

But it cannot make shapes as detailed as die casting.

Die casting fills the mold with pressure, so the parts come out smoother and more exact.

Why Hot Chamber Casting Cannot Use Aluminum

Hot chamber die casting is used for metals with low melting points. Aluminum melts at very high heat. This heat can damage the hot chamber machine

Surface Finishing Options for Aluminum Die Castings

Aluminum die cast parts often come out smooth, but many companies still add a finish. A finish helps the part look better, last longer, and stay safe from damage. There are several ways to finish aluminum parts.

Deburring and Cleaning

After a part is made, it may have tiny bumps or sharp edges. Deburring removes these small pieces so the part is safe to touch and use.

Then the part is cleaned to remove dirt, dust, or leftover oil. A clean surface helps other finishes stick better.

Conversion Coating

A conversion coating is a thin layer that protects the part. It helps remove any leftover metal particles and prepares the surface for paint or other finishes.

Anodizing

Anodizing makes the surface harder and more durable. It also gives the part a clean and bright look.

Anodizing helps:

- Stop corrosion

- Make the part stronger

- Add color if needed

Electroplating

Electroplating covers the aluminum with a thin metal layer. This layer makes the part look shiny and helps protect it from wear.

The process uses electricity to attach the metal to the part. It can use different metals depending on the look and strength needed.

Chrome Plating

Chrome plating is a special type of electroplating.

It gives the part:

- A bright silver look

- A very hard surface

- Extra corrosion protection

Powder Coating

Powder coating uses dry powder that sticks to the part. Then the part is heated, and the powder melts into a smooth coat.

This finish is:

- Strong

- Scratch resistant

- Colorful

- Long lasting

Polishing

Polishing makes the metal shiny and smooth. It can give the part a mirror-like look.

Some companies add wax after polishing to protect the shine and make the part last longer.

Environmental Impact and Sustainability

Aluminum die casting can be good for the environment, but it also has challenges. Many factories are working hard to make this process cleaner and safer for our planet.

Aluminum Can Be Recycled

One of the best things about aluminum is that it can be recycled again and again. It does not lose its quality when melted and reused.

- Save natural resources

- Reduce waste

- Lower the need for new raw materials

Low Waste Compared to Other Methods

Die casting uses most of the metal that goes into the mold. The extra metal from runners and gates can be melted again and reused.

This helps reduce waste during production.

Energy Use Is Still High

Even though aluminum is easy to recycle, the die casting process still uses a lot of energy.

Factories use energy to:

- Melt the aluminum

- Run large machines

- Keep molds at the right temperature

Pollution and Air Quality Challenges

Melting aluminum can release gases and small particles into the air. These can affect air quality and add to climate problems.

Factories must use filters and safe systems to lower these emissions.

Cleaner Technology Helps

Many companies are using new tools that use less energy and make less pollution.

Clean improvements include:

- Better furnaces

- Energy saving machines

- Improved cooling systems

- Smarter controls that save power

Closed Loop Systems

Some factories use a closed loop system. This means extra metal is collected, melted again, and reused right away.

- Reduce waste

- Save money

- Keep production clean and efficient

Using Renewable Energy

Some die casting plants now use wind, solar, or hydro power. This helps lower greenhouse gases and makes the whole process greener.

Challenges and Limitations of Aluminum Die Casting

Aluminum die casting has many benefits, but it also has some limits. Knowing these helps companies plan better and choose the right method.

Porosity Problems

Sometimes small air bubbles can get trapped inside the part. These bubbles make the part weaker. This problem is called porosity.

Factories must control the metal flow and cooling to reduce porosity.

High Tooling Cost

The initial tooling costs associated with aluminum die casting can be high. This is because the molds used in the process must be precisely machined and fabricated to ensure accuracy and consistency. This can make aluminum die casting a less attractive option for small production runs.

Limited Flexibility for Design Changes

Once the die is made, it is hard to change the design. If someone wants a new size or shape, they may need a whole new mold.

Not Good for Impact or Bearing Surfaces

Cast aluminum is strong, but it is not the best choice for parts that must take heavy hits or carry a lot of weight.

Can Have Stress Cracks

If the part cools too fast or has uneven walls, small cracks can form. These cracks make the part weaker and unsafe.

Material Waste in Some Steps

Even though extra metal is reused, some parts of the process still create waste. Trimming and removing extra metal creates scraps that must be melted again.

Future Trends in Aluminum Die Casting

The aluminum die casting industry is growing and improving. New technology is helping companies make better parts faster and with less waste.

Better Tools and Machines

New machines can make parts with very tight and exact sizes. Some can create details as small as 0.1 mm. This helps make cleaner and better fitting parts.

More Automation

Robots and smart machines are now used in many factories. They move parts, pour metal, and check quality.

Cleaner and Greener Tech

More companies are trying to use less energy and make less pollution. These changes help protect the environment.

Improved Alloys

New aluminum mixes are being made. These alloys are stronger, lighter, and better at handling heat. This helps companies create better parts for cars, planes, and electronics.

Selecting the Right Aluminum Die Casting Manufacturer for Your Project

Choosing the right die casting manufacturer is very important. A good partner helps you get strong, high quality parts that are made on time and within budget.

Questions to Ask When Vetting a Manufacturer

Before you choose a manufacturer, ask these helpful questions:

Do you have experience with my type of part?

You want a company that knows how to make parts similar to yours.

What alloys do you use?

A good manufacturer understands which aluminum alloy fits your job.

What quality checks do you use?

This includes measuring tools, testing machines, and inspection steps.

How do you control porosity and defects?

A skilled team can explain how they make clean and strong parts.

What is your production speed?

This helps you know if the company can meet your deadlines.

Can you help with design?

Some companies offer design help to make your part easier to cast.

Do you offer finishing services?

Finishes like powder coating or anodizing may be needed.

Case Studies or Examples

Here are simple examples of how choosing the right manufacturer helps:

Example 1: Automotive Company

A car company needed strong brackets for engines. They chose a die caster who used Alloy 380 and vacuum casting. The parts came out strong, smooth, and ready to use.

Example 2: Electronics Maker

A company needed thin parts for cooling systems. Their manufacturer used Alloy A383 because it flows well into tiny shapes. The parts fit perfectly into the final device.

Example 3: Outdoor Equipment Brand

A tool company needed parts that would not rust. The manufacturer used anodizing to protect the surface. The parts lasted longer in rain and sun.

Conclusion and Next Step

Aluminum die casting is a smart choice for many projects. It creates strong, light, and detailed parts that work well in cars, machines, and electronics.

If you want high quality results, you need the right manufacturer. Choose a team with good experience, strong tools, and clear communication.

When you are ready, reach out to a trusted aluminum die casting partner who can guide you from design to final production. Contact us today to get a free quote or to learn more about our services.