I. Introduction: The Industrial Gold Standard for Abrasion

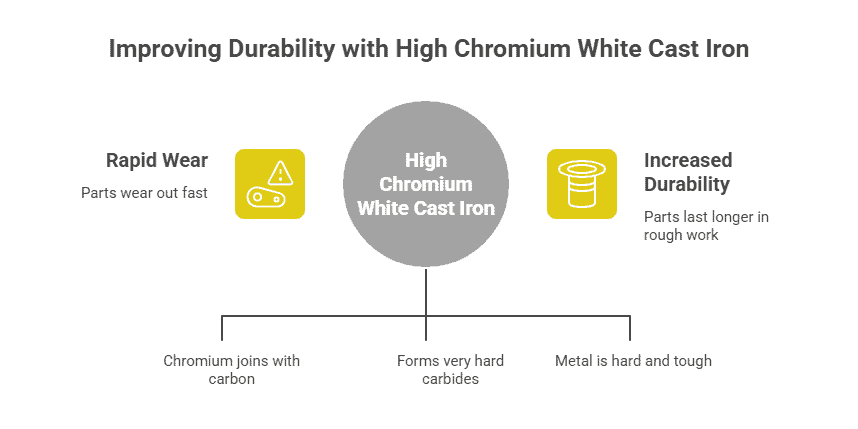

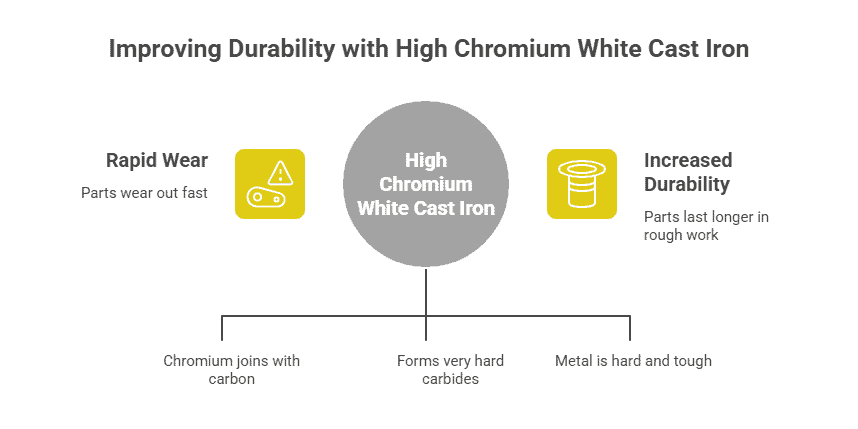

High chromium cast iron is one of the wear resistant materials used in a variety of applications where stability in an aggressive environment is a principal requirement. Higher chromium provide excellent oxidation and growth resistance for temperatures. Many heavy industries use it because it lasts longer in rough and harsh places. It works best where parts wear out fast.

Sand, rock, and ore often hit or rub metal parts. This causes damage called abrasion. High chromium cast iron handles this kind of damage very well.

This metal is different from normal cast iron. It contains a large amount of chromium. Chromium mixes with carbon inside the metal and forms very hard particles called carbides. These carbides protect the surface. They slow down scratching, cutting, and grinding.

The most important carbides in this metal are called M₇C₃ carbides. They are very hard and very strong. They help parts last longer in tough working conditions. Because of this, high chromium white cast iron performs better than regular white iron and many types of steel.

People use this metal in many heavy-duty parts, such as:

- Mining machines

- Grinding mills

- Slurry pumps

- Dredging equipment

High hardness is a big advantage. But it can also cause problems. Very hard metal can crack if it is too brittle.

The real goal is balance. The metal must resist wear, but it must also stay tough. When engineers find the right balance, parts last longer and work better in real jobs.

II. Core Properties of High Chromium White Cast Iron

High chromium cast irons (HCCIs) are specialized ferrous alloys that demonstrate exceptional wear resistance and mechanical properties. To fight this problem, many shops use High Chromium White Cast Iron (HCCI).

This metal is special. It lasts longer. It wears slower. And when used the right way, it saves money on repairs and downtime.

Why High Chromium White Cast Iron Is So Strong

High Chromium White Cast Iron gets its strength from:

- What it is made of

- How its inside structure forms

Both control hardness and wear life.

Chemical Composition (What’s Inside the Metal)

This metal mainly uses two elements:

- Chromium: 12% to 30%

- Carbon: 2% to 3.5%

Why this mix matters

- Chromium joins with carbon

- They form very hard carbides

- These carbides fight cutting and scratching

Shop tip:

More chromium usually means better wear life.

Too much carbon can make parts crack easier.

Balance is everything.

Microstructure: What the Metal Looks Like Inside

Inside the metal, there are two main parts:

- Hard M₇C₃ carbides (these do the fighting)

- The matrix (this holds everything together)

Think of it like this:

- Carbides act like armor

- The matrix acts like the body

Heat treatment decides if the matrix becomes:

- Austenite

- Martensite

- Or a mix of both

Why shape matters

- Fine carbides = longer life

- Big, sharp carbides = more crack risk

Good control gives better service in the field.

Mechanical Performance (What You See on the Job)

| Property | Performance |

| Abrasion resistance | Excellent |

| Toughness | Medium |

| Best use | Grinding, slurry, sliding wear |

This metal is not as tough as steel, but it lasts much longer in abrasion-heavy work.

III. The Role of Heat Treatment in Hardness Optimization

High Chromium White Cast Iron is hard.

But as-cast parts are not ready for work.

Heat treatment helps the metal:

- Get harder

- Last longer

- Break less often

Why As-Cast Metal Is Not Enough

As-cast parts contain retained austenite.

This phase:

- Is soft

- Wears faster

- Can change later during use

When it changes, parts may:

- Crack

- Change size

- Fail early

As-cast parts also trap internal stress from fast cooling.

Stress weakens parts and raises failure risk.

Heat treatment fixes these problems.

Destabilization Heat Treatment

This is the most common heat treatment for HCCI.

How it works

- Heat the casting to 900°C–1100°C

- Hold it for a set time

- Let small carbides form inside the metal

These secondary carbides:

- Pull carbon and chromium out of austenite

- Make austenite unstable

Cooling and Hardness Gain

After heating:

- Workers cool the part in air

During cooling:

- Weak austenite turns into martensite

- Martensite is very hard

Result

- Higher hardness

- Better wear life

- Stronger parts in service

Shop advice:

Too much heat or time can hurt the part.

Control the process for best results.

IV. Specialized Processing: Austempering High Chromium White Cast Iron

Sometimes hardness alone is not enough. Some parts also need impact strength. This is where austempering helps.

What Is Austempering?

Austempering is heat treatment that is applied to ferrous metals, most notably steel and ductile iron. It is primarily used to improve mechanical properties or reduce / eliminate distortion. The austempering of steel was first pioneered in the 1930s by Edgar C. Bain and Edmund S. Davenport, who were working for the United States Steel Corporation at that time.

Austempering is defined by both the process and the resultant microstructure. For example, they may be produced as-cast or air cooled with the proper alloy content. These materials are also not referred to as austempered.

Austempering creates metal that:

- Bends more before breaking

- Handles shock better

Some retained austenite stays inside on purpose.

This phase:

- Absorbs stress

- Slows crack growth

- Helps parts last longer

Hardness vs Impact: Choosing the Right Option

| Work Type | Best Choice |

| Heavy abrasion only | Destabilized HCCI |

| Abrasion + impact | Austempered HCCI |

Where austempering works best

- Pumps

- Crushers

- Mining and quarry parts

- Shock-loaded wear components

Real-world advice:

If parts keep cracking, hardness may be too high.

Austempering often fixes this problem.

V. Factors Affecting Final Hardness

Many things decide how hard High Chromium White Cast Iron becomes. From real shop experience, three factors matter the most:

- Alloy elements

- Cooling speed

- Heat treatment control

Getting these right helps parts last longer in tough jobs.

Alloying Elements (Small Changes Matter)

Some added elements help the metal harden better.

- Molybdenum (Mo)

Helps the metal harden evenly. It also stops soft structures from forming. - Nickel (Ni)

Adds strength, but too much keeps the metal soft. - Copper (Cu)

Helps a little, but too much can weaken the part.

🛠️ Shop advice:

Engineers must balance these elements. Too much of any one causes trouble instead of strength.

Cooling Rate (Fast vs Slow Cooling)

Cooling speed plays a big role.

- Fast cooling

Forms hard structures. Improves wear life. - Slow cooling

Forms soft structures like pearlite. Reduces hardness.

Thick parts cool slower than thin ones. Air flow, part size, and layout all affect cooling speed.

Retained Austenite (Helpful or Harmful?)

Some austenite stays after heat treatment.

- A small amount helps absorb stress

- Too much lowers hardness and causes size changes

To control it, engineers may:

- Cool parts faster

- Add extra heat steps

- Use sub-zero cooling if needed

Tempering Cycles

Tempering helps remove stress after hardening.

- Short tempering keeps parts hard

- Long or hot tempering softens the metal

Good tempering improves part life without losing wear resistance.

VI. Maintenance and Application Best Practices

Choosing the right grade matters. Not every job needs the same hardness.

Engineers often use ASTM A532 to pick the correct grade. This standard groups materials by chromium level and wear type. The right grade means fewer failures and longer service life.

Welding and Machining

Welding

High Chromium White Cast Iron is hard to weld.

- It cracks easily if heated and cooled too fast

- Workers must preheat parts

- Special filler metals help reduce cracks

Machining

Machining is also difficult.

- Hard carbides wear tools fast

- Most machining happens before final heat treatment

- Many parts are cast close to final shape

Real-world tip: Good design saves time, reduces repairs, and lowers cost over time.

Cooling and Hardness Increase

After heating, workers cool parts in air or forced air.

During cooling:

- Unstable austenite changes into martensite

- Martensite is very hard and strong

This change:

- Increases hardness

- Improves wear resistance

- Helps parts last longer in harsh work

VIII. Troubleshooting Destabilization Heat Treatment Issues and Case Studies

Destabilization heat treatment improves hardness and wear life. But problems can appear if engineers do not control the process. Understanding these problems helps prevent failure.

Common Problems After Destabilization

Some parts show defects after heat treatment. The most common problems include:

- Low hardness

- Cracking

- Too much retained austenite

- Large or uneven carbides

These problems reduce wear life and can cause early failure.

Carbide Coarsening and How to Fix It

Carbide coarsening happens when the metal stays too hot for too long. Large carbides form and spread unevenly. These carbides make cracking easier.

To reduce carbide coarsening:

- Do not overheat the casting

- Avoid long holding times

- Use controlled heating rates

- Match time and temperature to part thickness

Fine and evenly spaced carbides give better wear and strength.

How to Reduce Retained Austenite

Too much retained austenite lowers hardness. It can also cause size changes during service.

Engineers reduce retained austenite by:

- Using the correct destabilization temperature

- Cooling fast enough after heating

- Adding sub-zero cooling when needed

- Using light tempering cycles

Case Study 1: Destabilization at 950°C

At 950°C, secondary carbides form slowly. The matrix loses some carbon and chromium. Martensite forms during cooling.

Results:

- Good hardness

- Fine carbides

- Moderate retained austenite

- Better toughness

This temperature works well for parts that need wear resistance with some impact.

Case Study 2: Destabilization at 1000°C

At 1000°C, carbide precipitation increases. The matrix loses more carbon. Martensite formation improves.

Results:

- Higher hardness

- More secondary carbides

- Lower retained austenite

- Higher crack risk if not controlled

This temperature works best for pure abrasion with low impact.

Comparison of Results

| Feature | 950°C | 1000°C |

| Hardness | High | Very High |

| Carbide Size | Fine | Larger |

| Retained Austenite | Moderate | Low |

| Crack Risk | Lower | Higher |

VII. Conclusion

High-chromium white iron represents a crucial category of wear-resistant materials in manufacturing applications. Its widespread use in mining and minerals processing stems from its outstanding abrasion resistance, attributed to the presence of hard alloy eutectic carbides within its microstructure.

Its hard carbides protect parts from grinding and cutting damage. That is why mining, milling, and slurry systems rely on it.

Heat treatment makes the biggest difference:

- Destabilization improves hardness and wear life

- Austempering improves toughness and crack resistance

The key is balance. Too much hardness causes failure. Too little causes fast wear.

With proper heat treatment and control, High Chromium White Cast Iron will continue to be a trusted material for demanding industrial work.