Making strong parts is important in many industries. Machines need grooves, slots, and smooth 3D shapes to work. Gantry CNC milling machines can cut both simple and complex parts. They do this with high precision. These machines can also handle very large pieces. Other mills cannot do this.

In this article, you will learn about groove machining. You will also learn about surface machining. Finally, you will see why gantry CNC milling is best for big and complex jobs.

What is Groove Machining?

Grooving in machining refers to the process of cutting narrow channels or recesses on the surface of a workpiece. It is an essential step in preparing components for assembly or for creating pathways for seals, O-rings, or other similar elements.

This operation is typically performed on CNC machines and involves specialized cutting tools designed for the task. The grooving process is precise, requiring attention to detail to ensure the desired depth and width of the groove is achieved without causing damage to the workpiece.

Grooves are found in many parts:

- Keyways – slots in shafts that pass torque between gears or pulleys.

- Straight slots – used for alignment and fixtures.

- O-ring grooves – channels that hold seals in pumps, valves, and engines.

- Snap ring grooves – circular cuts that keep rings in place on shafts or inside holes.

Grooves can be cut in many materials:

- Steel – strong, durable, often used in heavy machinery.

- Aluminum – light, common in cars and planes.

- Plastics and composites – used in seals or electrical housings.

- Copper and brass – chosen for corrosion resistance or conductivity.

Modern CNC machines can cut grooves with high precision. Accuracy often reaches ±0.01 mm. Surface finish can be controlled as well, which is key for sealing grooves or parts that carry loads.

What is Spatial Surface Machining?

Spatial surface machining means cutting and shaping complex 3D surfaces. Instead of flat or straight cuts, you work with curves, angles, and changing depths. This type of machining creates parts that must match exact 3D shapes.

You use computer-controlled machines to move a tool along many paths. The tool cuts small amounts of material until the full surface is shaped. Every pass adds detail and accuracy. This method allows you to build parts that normal milling cannot produce.

You see spatial surface machining in advanced industries:

- Aerospace parts – like fuselage panels and structural joints.

- Turbine blades – shaped for airflow and efficiency in jet engines or power plants.

- Molds and dies – used to form plastics, metals, or composites into complex shapes.

- Medical implants – curved surfaces that must fit the human body.

These parts must fit and perform with no room for error. A turbine blade with the wrong curve loses efficiency or fails. A mold that is off by a fraction of a millimeter ruins every product it makes. Gantry CNC machines give you the precision and repeatability needed. Their rigid structure and multi-axis control let you cut exact 3D surfaces at large scales.

Introduction to Gantry Milling Machines

A gantry milling machine is a type of mill with a bridge-like frame. This frame is called a gantry. It spans the workpiece. The cutting tool moves across the frame to shape large and heavy parts. You use gantry mills when a part is too big or heavy for vertical or horizontal mills.

The gantry frame stands on two columns. A cross beam connects the columns. The tool head moves along the beam. It can travel side to side, front to back, and up and down. The workpiece stays fixed on the bed. The tool moves to do the cutting. This design makes the machine rigid and strong. It can handle very large parts without losing accuracy.

- Manual Gantry Milling – The operator controls the movement by hand or simple feeds. It is slower and less precise. It is used for basic jobs.

- CNC Gantry Milling – Computer Numerical Control (CNC) guides the tool with programmed instructions. It allows multi-axis movement, repeatable results, and complex machining with high accuracy.

Gantry milling machines give you several benefits:

- Large workpiece capacity – They can hold parts several meters long and very heavy.

- Rigidity – The bridge design resists vibration. This keeps cuts accurate.

- Precision – CNC gantry mills hold tight tolerances even on oversized parts.

- Flexibility – They can cut simple grooves or complex 3D surfaces in the same setup.

Gantry CNC Milling Machines

CNC stands for Computer Numerical Control. You program the machine to follow exact paths. The computer moves the cutting tool step by step. This makes the process faster and more accurate. It also gives you repeatable results. CNC lets you make complex parts that are not possible with manual control.

CNC gantry mills can move in several axes:

- 3-axis – moves up and down, side to side, and front to back.

- 4-axis – adds rotation, so you can cut around the part.

- 5-axis – tilts and rotates the tool, so you can reach deep curves and angles.

More axes mean fewer setups. They save time and give you higher accuracy on complex parts.

You design a part in CAD (Computer-Aided Design). Then CAM (Computer-Aided Manufacturing) turns that design into machine code. The CNC gantry mill follows the code to cut the exact shape. This link between design and machining reduces mistakes and saves time.

CNC gantry mills handle both simple and advanced work. They cut straight grooves, slots, and keyways. They also shape complex 3D surfaces like molds, turbine blades, and dies. That is why many industries use them for jobs that need accuracy and scale.

Large Gantry Milling Machines for Heavy-Duty Workpieces

Large gantry milling machines are built for very big parts. The machine bed can be several meters long and wide. Some machines cut parts over 20 meters in length and weighing many tons. You use them when parts are too large for standard mills.

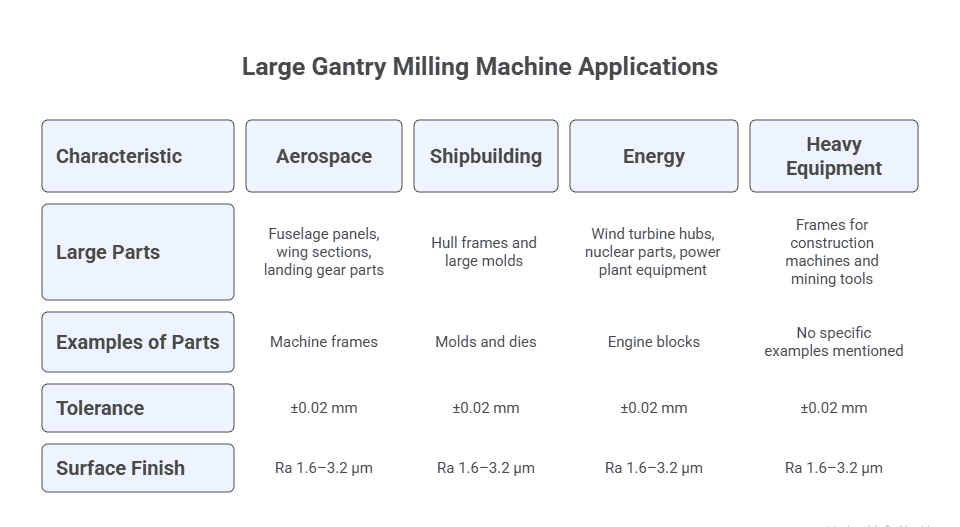

These machines serve industries that need oversized components:

- Aerospace – fuselage panels, wing sections, landing gear parts.

- Shipbuilding – hull frames and large molds.

- Energy – wind turbine hubs, nuclear parts, power plant equipment.

- Heavy equipment – frames for construction machines and mining tools.

Common parts made on large gantry mills include:

- Machine frames – bases for industrial machines.

- Molds and dies – for plastics, composites, and metals.

- Engine blocks – for ships, power plants, and heavy vehicles.

Even at large scale, these machines hold tight tolerances. Many can cut within ±0.02 mm. They also deliver smooth surface finishes (Ra 1.6–3.2 µm). This is critical for sealing, assembly, and reducing wear.

Groove & Surface Machining with Gantry CNC: Key Advantages

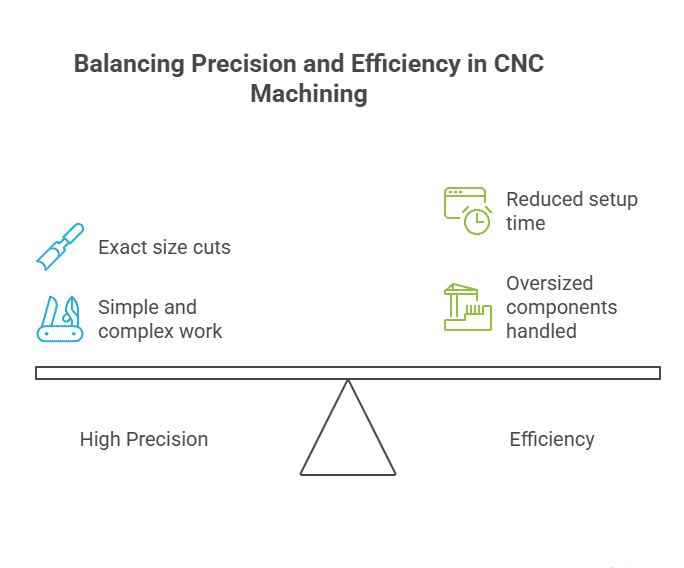

CNC control cuts grooves and surfaces to exact size. You can repeat the cut many times with the same result. This keeps every part within design limits.

One gantry CNC machine can cut both straight and curved features. It handles keyways, slots, and O-ring grooves. It also shapes 3D parts like turbine blades, molds, and dies. This makes the machine useful for many kinds of jobs.

Large gantry mills cut heavy parts in one setup. You do not need to move the part to other machines. This saves time and lowers the chance of mistakes.

Multi-axis movement lets the tool reach more surfaces in one run. You set the part once and finish more work. This shortens machining time and improves accuracy.

Groove Machining vs. Other Milling Processes

Groove Machining vs. Slotting vs. Drilling

Each process has a different job. Groove machining cuts channels. Slotting makes straight cuts. Drilling makes round holes.

| Process | Purpose | Shape | Precision | Common Use |

| Groove Machining | Cuts channels for fit or seal | Straight, circular, curved | Very high (±0.01 mm) | Keyways, O-ring grooves, snap rings |

| Slotting | Makes straight cuts in material | Rectangular slot | Moderate | Fixtures, key seating |

| Drilling | Produces holes | Circular hole | Moderate to high | Fastening, fluid flow |

Gantry Milling vs. Vertical/Horizontal Milling Machines

Gantry mills are different from vertical or horizontal mills. They cut larger parts and resist vibration better.

| Machine Type | Workpiece Size | Rigidity | Precision | Common Use |

| Gantry Milling | Very large, heavy parts | Very high | High (±0.02 mm) | Aerospace, shipbuilding, molds |

| Vertical Milling (VMC) | Small to medium parts | Moderate | High (±0.01 mm) | General machining, automotive |

| Horizontal Milling (HMC) | Medium to large parts | High | High (±0.01 mm) | Production, heavy-duty cutting |

Cost-Efficiency and Scalability

- Groove machining cuts cost by reducing errors in sealing and assembly.

- Gantry machines handle large parts in fewer steps, saving time.

- For small parts, vertical or horizontal mills may be cheaper.

- For very large parts, gantry CNC machines give the best mix of cost, speed, and accuracy.

Industries Using Gantry CNC Milling Machines

In modern manufacturing, precision and efficiency have always been the two core goals pursued by enterprises. Among them, the gantry CNC milling machine has become an indispensable and important tool in the field of modern manufacturing with its unique structural design and excellent performance.

Gantry CNC machines make large and precise parts for planes and spacecraft. They cut turbine blades, wing sections, fuselage panels, and landing gear parts. These parts must meet strict safety and performance rules.

In the auto industry, gantry CNC machines cut molds and dies for body panels and engine parts. They are also used for electric vehicle components. Accuracy and smooth surface finish are critical in these parts.

Bulldozers, cranes, and mining tools use strong frames and housings. Gantry CNC machines cut these oversized parts in one setup. The rigid frame keeps cuts accurate, even on thick steel.

The energy sector needs very large and heavy parts. Gantry CNC machines make wind turbine hubs, power plant casings, and nuclear components. These parts demand tight tolerances. Failure here can cause major breakdowns.

Choosing the Right Gantry Milling Machine or Service Provider

When choosing a gantry milling machine, focus on:

- Machine size – Match the part size to the bed size.

- Accuracy – Check the tolerances the machine can hold.

- Axis capability – Choose 3, 4, or 5-axis. More axes give more flexibility for complex surfaces.

In-House vs. Outsourcing

- In-house machining – Works if you have steady demand and the budget for equipment. You gain full control but face high upfront costs.

- Outsourcing – Better if you need large or complex parts only at times. A supplier already has the machines and skilled staff.

Tips for Selecting a Supplier

- Review their machine list and confirm they can handle your part size.

- Check their tolerance records and ask for project samples.

- Make sure they use modern CAD/CAM systems.

- Look for industry experience in your field, like aerospace or energy.

Why Choose Huasuma?

At Huasuma, we make very strong and accurate machine parts. We use big gantry CNC machines that can cut large and heavy pieces with high precision. Our machines can move in many directions, so we can shape both simple grooves and complex 3D surfaces.

Our company is located in the Tongshan High-Tech Development Zone of Xuzhou, Jiangsu Province. Founded in 2019, it occupies a land area of 30,000 square meters, with workshop space covering approximately 15,000 square meters. The company holds multiple national patents, participates in developing industry standards, and exports to over 60 countries worldwide.

When you work with Huasuma, you get:

- Modern machines can handle very large parts.

- A skilled team that knows how to cut grooves, smooth 3D shapes, and handle heavy parts.

- Reliable results that meet the high standards needed in industries like airplanes, cars, energy, and construction machines.

Conclusion

Groove machining creates channels for keys, seals, and rings. Spatial surface machining builds complex 3D shapes like turbine blades and molds. Gantry CNC milling combines power, accuracy, and scale.

Large gantry machines cut parts that no other mill can handle. They save setup time, hold tight tolerances, and serve many industries. For large and complex parts, gantry CNC milling is the best solution.

Contact us for precision groove machining and large-scale CNC services.