Stainless steel is strong, but it has trouble in very high temperatures. When it gets too hot, the steel reacts with oxygen in the air. This makes a thin layer on the surface that can crack and fall off. When this happens, the steel wears out faster and can break early.

To fix this problem, engineers add tiny amounts of rare earth metals to the steel. These special alloys help the steel stay protected for a much longer time. Today, rare earth alloys are very important for work in extreme heat.

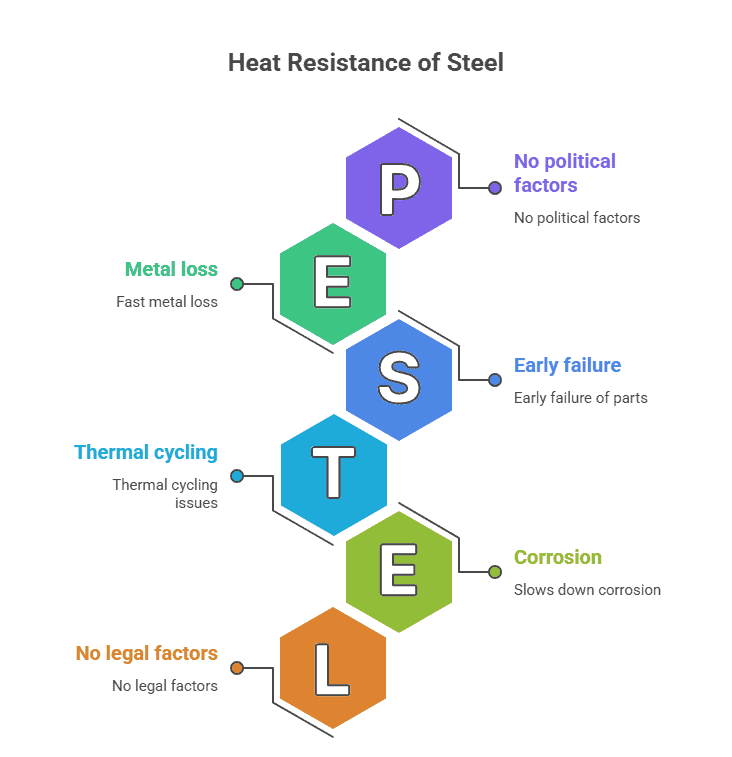

Understanding Heat Resistance of Steel

Heat resistance means steel can stay strong and keep its shape in high heat. Stainless steel’s composition is made from iron alloyed with chromium. When the chromium content is added to the iron alloy and reaches 10.5% or more, it reacts with oxygen to create a razor-thin protective film called chromium oxide. This protective layer is what makes stainless steel different from ordinary steel.

How Stainless Steel Protects Itself

Stainless steel contains chromium. When heated, chromium reacts with oxygen and forms a thin protective layer on the surface. This layer is called chromium oxide, written as:

Cr2O3Cr_2O_3Cr2O3

This oxide layer works like a shield. It:

- Blocks oxygen from reaching the metal

- Slows down corrosion

- Helps the steel last longer at high temperatures

As long as this layer stays attached, the steel remains protected.

Why the Protective Layer Fails

Problems begin at very high temperatures or when steel heats up and cools down many times. This is called thermal cycling.

During thermal cycling:

- Steel expands when heated

- Steel shrinks when cooled

- The oxide layer expands and shrinks at a different rate

This difference creates stress between the metal and the oxide layer. Over time:

- Cracks form

- The oxide layer loosens

- Pieces of the layer fall off

This flaking is known as spalling.

Why Spalling Is Dangerous

When spalling happens:

- Fresh metal is exposed to oxygen

- A new oxide layer forms

- The new layer also flakes off

This cycle repeats again and again, causing:

- Fast metal loss

- Thinner steel sections

- Early failure of parts

Heat Resistant vs Oxidation Resistant Steel

These two terms are not the same:

- Heat resistant steel keeps its strength at high temperatures

- Oxidation resistant steel protects itself from oxygen damage

A steel can be heat resistant but still fail if it oxidizes too.

The Role of Rare Earth Elements (REEs) in Metallurgy

A rare earth element (REE) is defined as an element from the lanthanide series, comprising 15 elements, along with Scandium and Yttrium, that are increasingly important for various technological applications such as permanent magnets and electric vehicles.

Rare earth elements are a group of special metals used in very small amounts. Even though their name says “rare,” many of them are found all over the world. What makes them special is how they behave inside metal.

In metallurgy, rare earth elements are added in tiny amounts to improve how metals perform, especially at high temperatures.

Common Rare Earth Metals Used in Steel

The most common rare earth elements used in heat resistant stainless steel are:

- Cerium (Ce) Helps oxide layers stick better to the steel surface.

- Lanthanum (La) Makes the oxide layer more stable and less likely to crack.

- Yttrium (Y) Strongly improves oxide adhesion and slows down oxidation.

These elements are usually added at less than 0.5% of the total alloy.

Why Rare Earth Elements Work So Well

Rare earth elements (REEs) play a quiet but foundational role in many of the technologies we rely on daily.

- They bond strongly with oxygen

- They move easily to grain boundaries inside the steel

- They settle at weak points where damage often starts

Because of this, they act like “helpers” that fix problem areas in the metal.

Small Amounts, Big Results

Unlike chromium or nickel, rare earth elements do not change the strength of steel very much. Instead, they improve how the steel protects itself.

Even tiny additions can:

- Improve oxidation resistance

- Reduce surface cracking

- Extend service life by many years

This is why rare earth alloys are used in very demanding heat applications.

Why Engineers Use REEs

Engineers choose rare earth elements because they:

- Solve problems chromium cannot

- Work at extreme temperatures

- Improve long-term reliability

How Rare Earth Alloys Improve Oxidation Resistance

Rare earth elements may be added in very small amounts, but they make a very big difference. They change how the steel surface behaves at high temperatures. This improvement happens through several important mechanisms.

The Reactive Element Effect (REE)

The main reason rare earth alloys work so well is called the Reactive Element Effect.

When rare earth elements are added to stainless steel:

- They move toward the surface of the metal

- They sit between the steel and the oxide layer

- They change how the oxide layer grows and sticks

Because of this effect:

- Oxide layers grow more slowly

- The oxide layer becomes thinner and denser

- The surface stays protected for a longer time

Even less than 0.1% of a rare earth element can create this effect. This makes rare earth alloys very efficient and cost-effective for high-temperature use.

Strengthening Grain Boundaries

Inside steel, there are tiny regions called grain boundaries. These are weak spots where damage often starts.

At high temperatures, harmful impurities like sulfur move toward these grain boundaries. Sulfur weakens the bond between the metal and the oxide layer. This makes spalling more likely.

Rare earth elements solve this problem by:

- Trapping sulfur and other impurities

- Keeping them away from grain boundaries

- Strengthening the metal structure

This results in:

- Better metal bonding

- Fewer cracks

- Longer service life

Improving Oxide Layer Adhesion

One of the biggest problems in heat resistant stainless steel is oxide layer flaking, also called spalling.

Rare earth elements help the oxide layer stay attached by:

- Anchoring the oxide layer to the metal surface

- Reducing stress between the metal and oxide

- Making the oxide layer grow more evenly

Because of this:

- The oxide layer does not peel off easily

- The steel survives sudden temperature changes

- Thermal shock damage is reduced

This is especially important in industries where equipment heats up and cools down many times.

Controlling Oxygen Diffusion

Oxidation happens when oxygen moves into the steel and reacts with it. Rare earth elements slow this process down.

They do this by:

- Blocking fast paths where oxygen travels

- Making it harder for oxygen to reach the metal

- Slowing the movement of metal atoms toward the surface

As a result:

- Oxidation happens much more slowly

- Less metal is lost over time

- The steel keeps its thickness and strength

Why This Improves Steel Lifespan

All these effects work together. Rare earth elements do not stop oxidation completely, but they control it.

- Oxide layers stay attached

- Spalling is greatly reduced

- Steel lasts longer at extreme temperatures

This is why rare earth alloys are now used in the most demanding heat applications.

Comparing Common Heat Resistant Stainless Steel Grades

Not all stainless steels work the same at high temperatures. Some steels can handle heat for a short time, while others can work in very hot places for many years. The big difference is whether the steel contains rare earth elements or not.

Standard Heat Resistant Stainless Steel

310S stainless steel is a common type of heat resistant steel. It contains chromium and nickel, but it does not contain rare earth elements.

- It can work up to about 1035°C

- It forms a protective oxide layer

- The oxide layer can crack and fall off

- It works best in normal industrial heating

This steel is good for medium heat, but it does not last long in very high temperatures.

Stainless Steel with Rare Earth Elements

When rare earth elements are added, steel can handle much more heat and last longer.

| Steel Type | Rare Earth Added | Max Temperature | Where It Is Used |

| 310S Standard | None | 1035°C | General factories |

| High-temperature Ferritic | Yttrium | 1150°C | Car exhaust systems |

| Advanced Austenitic | Cerium / Lanthanum | 1200°C or more | Industrial furnaces |

Why Rare Earth Steels Are Better

Steel with rare earth elements:

- Keeps the oxide layer stuck to the surface

- Does not flake easily

- Loses less metal over time

Because of this, it stays strong much longer.

Picking the Right Steel

Engineers must think about:

- How hot it will get

- How often it heats and cools

- How long the part must last

For very high heat, rare earth alloys are the better choice.

Industrial Applications of Rare Earth Alloys

Rare earth alloys are key to modern materials. They improve the properties of metals, plastics, and ceramics. Adding rare earths enhances strength, durability, and heat resistance.

Many industries use rare earth alloys as additives. They are important in aerospace, automotive, and energy systems. For example, they prevent corrosion in metals and increase efficiency in energy storage. Rare earth alloys also improve performance in electronics and advanced manufacturing.

Aerospace Industry

In airplanes and rockets, parts face extreme heat and stress.

Rare earth alloys are used in:

- Engine parts

- Combustion chambers

- Hot air flow areas

These parts heat up and cool down many times. Rare earth alloys stop oxide layers from cracking and falling off, which helps keep the parts safe and strong.

Energy Generation

Power plants use equipment that runs at high temperatures for long periods.

Rare earth alloys are used in:

- Boilers

- Heat exchangers

- Nuclear reactor parts

These parts must resist oxidation for many years. Rare earth elements slow down oxidation and reduce metal loss, which lowers repair costs.

Automotive Industry

Modern cars produce a lot of heat, especially in the exhaust system.

Rare earth alloys are used in:

- Turbocharger housings

- Exhaust manifolds

- Catalytic converter parts

These parts are thin and heat up very fast. Rare earth elements help the oxide layer stay in place and prevent damage from heat cycles.

Manufacturing and Industrial Furnaces

Factories use furnaces that operate at very high temperatures every day.

Rare earth alloys are used in:

- Furnace trays

- Heat treatment fixtures

- Glass-making equipment

Because these parts heat and cool many times, rare earth alloys help them last longer and reduce shutdown time.

Why Industries Choose Rare Earth Alloys

Companies choose these alloys because they:

- Last longer

- Reduce maintenance

- Improve safety

- Save money over time

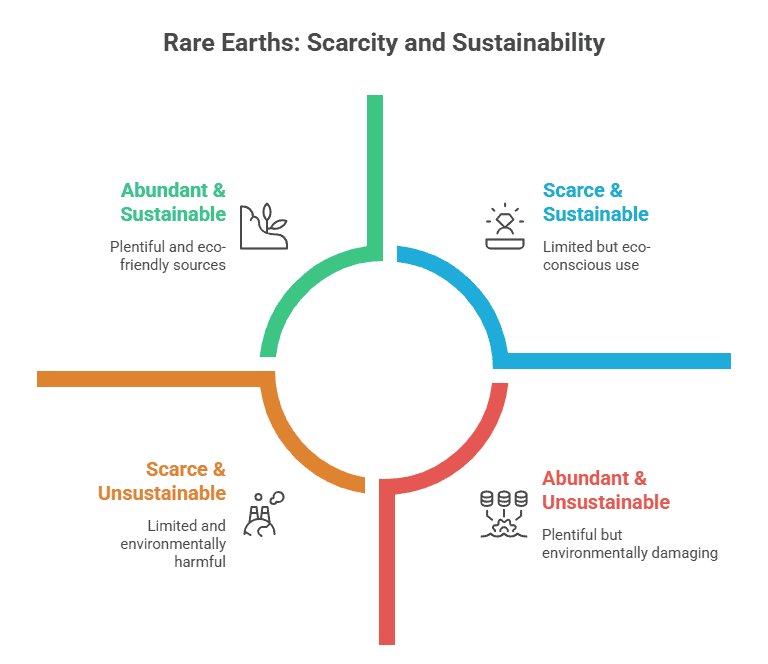

Future Trends: Scarcity and Sustainability of Rare Earths

Rare earth elements are very helpful, but they are hard to make. They are found in only a few places in the world, and mining them takes time and money. Because of this, supplies can change and prices can rise or fall.

Many industries need rare earth elements. They are used in steel, electronics, and clean energy. This makes it important to use them carefully.

To help with this, engineers are finding new ways to use rare earth elements. One idea is to use very small amounts but still get the same results. Even tiny amounts can protect steel if used correctly.

Scientists are also improving alloy designs. They study how rare earth elements work on the surface of steel so they can put them exactly where they help the most.

Conclusion

Heat resistant stainless steel must work in very hot places without getting damaged. When the heat is too high, normal stainless steel can stop working due to protective layer cracks. Rare earth alloys help fix this problem by keeping the protective layer strong and in place. Even tiny amounts of rare earth metals can help the steel last much longer. Today, rare earth alloys are very important for high heat use. Picking the right steel means thinking about heat, surroundings, cost, and how long it needs to last.