Ever wondered how modern machinery or bridges handle all stress without cracking? Moreover, what’s the base material that they don’t even catch rust over time? The answer often lies in a single material, low-alloy steel.

In modern times, low-alloy steel has turned into the backbone of heavy industries. Diverse industries use low alloy steel in one form or another, from construction machinery to energy plants. It’s flexible, affordable, and yet high-performing.

In this blog, we will learn more about low alloy steel material, its composition, and properties. We will also see why this material is different from stainless and high-alloy steels.

What Is Low Alloy Steel?

In general, there are two major classifications of steel.

- Stainless steel (or high alloy steel)

- Low alloy steel

As the term establishes, low alloy steel contains a small percentage of alloying elements such as chromium, nickel, vanadium, molybdenum, and others. Usually, low alloy steel contains just 8-10% of alloying elements. Sometimes, even less than that.

Although the added alloys seem minor in quantity, they make a significant improvement:

- Improve the steel’s strength and hardness.

- Build steel resistant to everyday wear and tear.

- Don’t let it lose flexibility or machinability.

- Enhance metal performance for diverse applications.

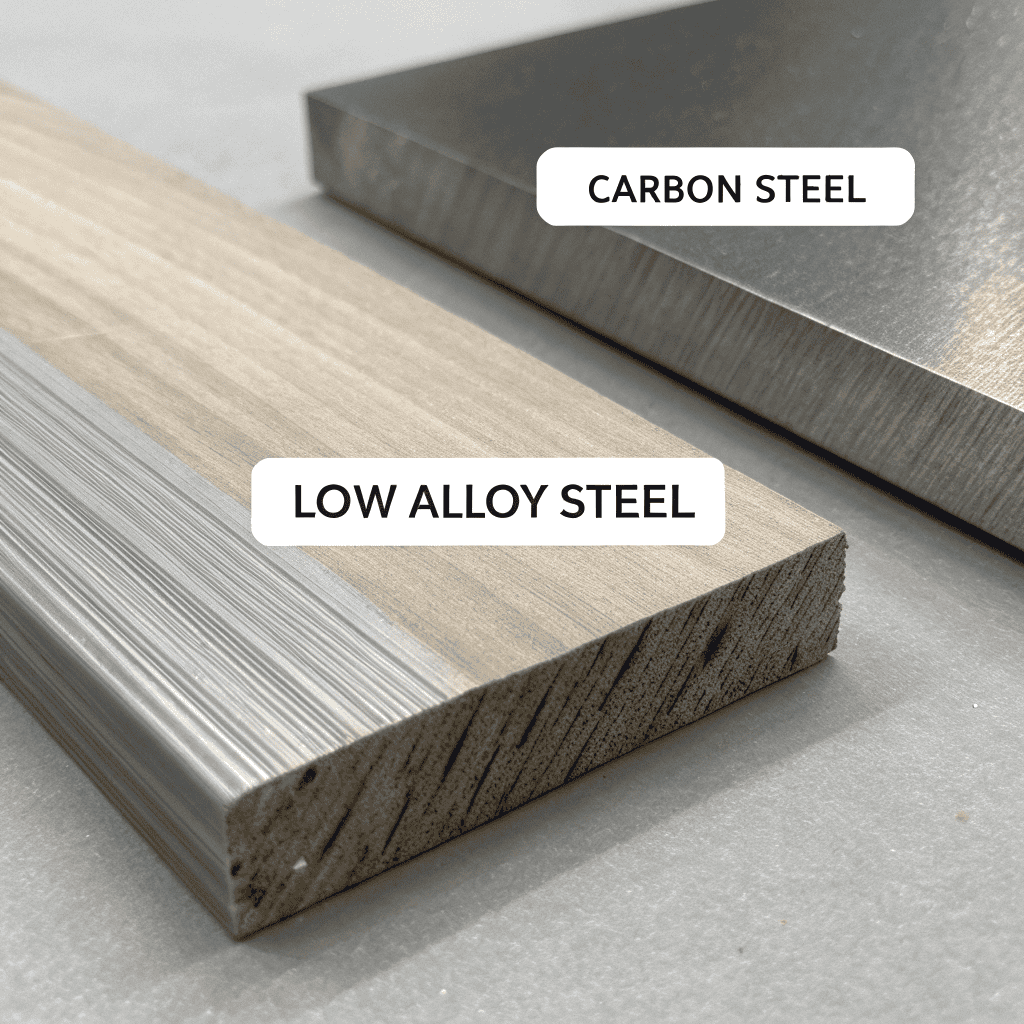

What’s the Difference Between Low Alloy Steel and Carbon Steel?

People often confuse low-alloy steel with plain carbon steel, which is not true. Rather, low-alloy steel is a distinct variety. The following table compiles the differences between low-alloy steel and carbon steel.

| Feature | Carbon Steel | Alloy Steel |

| Composition | Iron + Carbon | Iron + Carbon + Alloying Elements |

| Durability | Moderate | Higher |

| Corrosion Resistance | Low | Improved |

| Cost | Lower | Slightly higher |

| Applications | Basic construction, tools | Heavy machinery, automotive, pipelines |

In simple words, low alloy steel is the “upgraded version” of plain carbon steel. It’s tougher, more reliable, and a better fit for industrial use.

Composition of Low Alloy Steel

Though low in amounts, low-alloy steel may contain various alloys. The added alloys decide the final quality of the material.

The table given below highlights the list of elements added to low alloy steels and their estimated composition.

| Element | General Alloy Percentage |

| Carbon (C) | 0.2-0.5% |

| Chromium (Cr) | 0.5-1.5% |

| Manganese (Mn) | 0.5-1.5% |

| Nickel (Ni) | 0.5-2% |

| Molybdenum (Mo) | 0.2-1% |

| Vanadium (V) | 0.05-0.2% |

How Composition Affects the Properties

The chemical composition shapes the real properties of the material. Here’s how different elements decide the strength and quality of low-alloy steel:

- Carbon, manganese, and nickel add to the base strength and hardness.

- Chromium builds corrosion resistance in low alloy steel material.

- Molybdenum and vanadium make the steel durable even in high temperatures.

Key Properties of Low-Alloy Steel

Here are the key properties of low-alloy steel that make it different from other types of steel.

- Affordable Cost

Unlike stainless steel, low alloy steel has fewer alloying elements. Therefore, it’s affordable compared to other materials. But this low cost never means quality compromise.

Low alloy steel is still durable, corrosion-resistant, and heat-resistant. Therefore, it is the best fit for the projects where clients are looking for cost savings and high performance.

- High Strength & Toughness

One of the best features of low-alloy steel is that it can show outstanding strength. A few low-alloy steel types are stronger than stainless steel. Due to the addition of diverse elements, low alloy steel has tensile and yield strength.

It can withstand the heavy everyday wear and tear without any quality deterioration. This makes the low alloy steel material an ideal choice for high-stress environments like excavators and hydraulic systems.

- Good Fatigue Resistance

Let’s be honest. Failure is the ultimate part of every journey, especially for alloy steels. However, low-carbon alloy has good fatigue resistance. It can withstand failure under repeated or cycling loading.

Or, in other words, even when there is repeated stress, low alloy steel surpasses it without cracking. Fatigue resistance makes it perfect for industries like aerospace and automobiles.

- Moderate Corrosion Resistance

Both low alloy steel and high alloy steel resist rust. Yes, you heard it right. Thanks to the added elements like chromium and nickel. Low-alloy steel can withstand environmental factors like moisture and chemicals (even at extremes).

So, even after years of outdoor applications, it doesn’t affect the appearance of the low alloy steel material. It preserves its structural integrity and appeal for the long term.

- Excellent Weldability and Machinability

Manufacturers love using low alloy steel for its enhanced mechanical properties. It responds well to the heat treatment.

So, low alloy steel material can be easily cut and welded into the desired shape and size. The adaptability of low alloy steel to machines and tools saves a lot of time and cost.

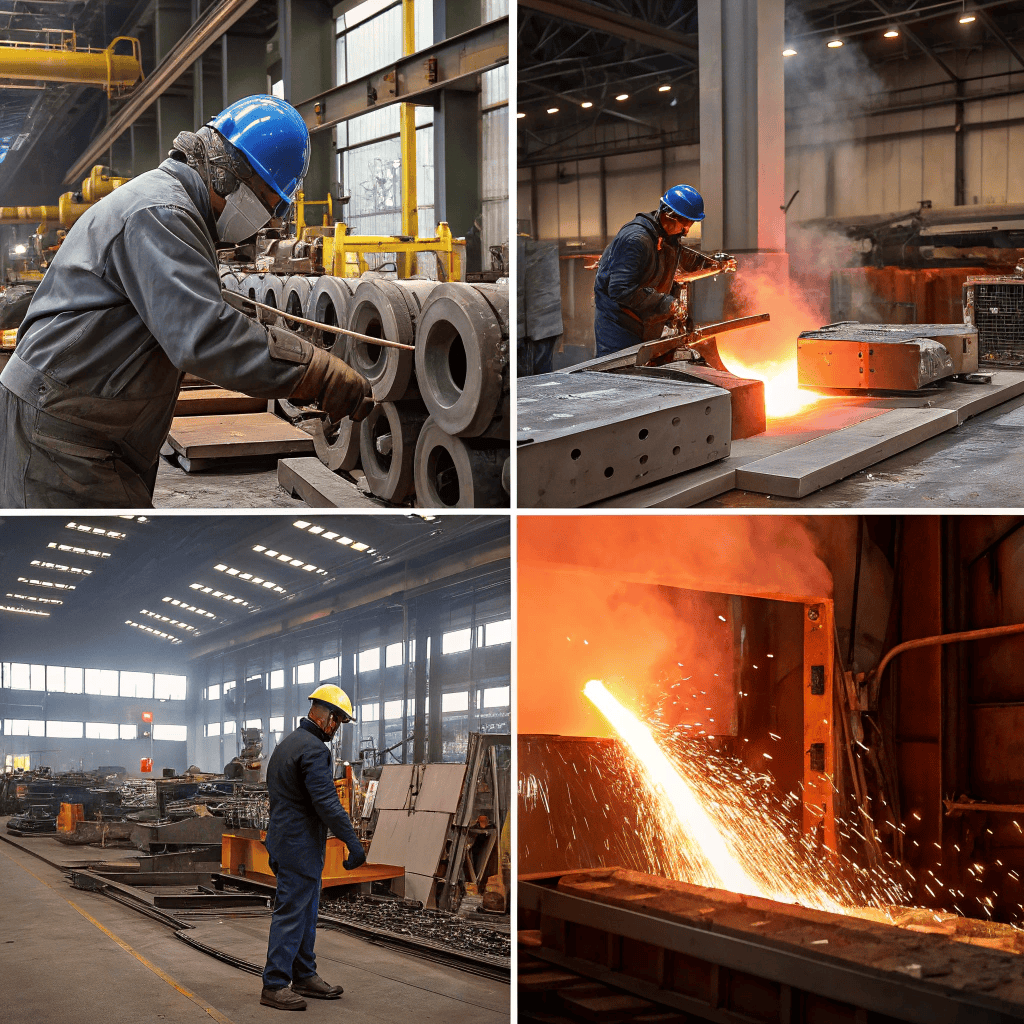

Manufacturing and Heat Treatment of Low-Alloy Steel

Let’s see how manufacturers produce low-alloy steel.

Manufacturing low-alloy steel isn’t a one-step process. It involves several controlled steps that define its final quality.

Step 1: Melting and Alloying

First, the raw materials are melted in a furnace. Later, alloy elements are added and mixed together with precision.

Step 2: Casting

The molten alloyed steel is then cast into molds to achieve the desired shape. Hot rolling helps the steel to gain shape, like sheets, bars, and plates. The shape of molds may vary depending on the projects.

Step 3: Heating of Low Alloy Steel

This is the step where the real magic happens. Heating helps low alloy steel material to build a structure and gain strength. Common heating techniques include:

- Tempering: To reduce brittleness and strengthen balance.

- Normalizing: To refine grain structure and build high strength low alloy steel.

- Quenching: A rapid cooling process to increase the steel’s hardness.

What are the Common Standards and Grades for Low Alloy Steel?

The typical grade and standards of low alloy steel material include:

AISI 4140

Include chromium and molybdenum as the primary alloys. Known for its high strength and toughness.

AISI 4340

It is called Nickel-Chromium-Molybdenum Steel. Popular for its superior fatigue resistance.

ASTM A572

High Strength Low Alloy (HSLA) Structural Steel or ASTM A572 is known for its durability. It is widely used in construction, like bridges and buildings.

There are other grades and variations also available that manufacturers use for projects.

What Is High Strength Low Alloy Steel (HSLA)?

You might have heard of the term High Strength Low Alloy Steel. Let’s see what it means. It’s the subclass of low-alloy steels designed for maximum strength with minimal weight.

How Is It Different

These steels include microalloying elements like niobium, titanium, and vanadium. Such alloys enhance the strength through grain refinement. The table given below explains the clear difference between low alloy steels and high strength low alloy (HSLA) steel.

| Property | Regular Low Alloy Steel | High Strength Low Alloy Steel |

| Strength | High | Very High |

| Weight | Moderate | Lighter |

| Cost | Affordable | Slightly Higher |

Common Applications of High Strength Low Alloy (HSLA) Steels

The common applications of high strength low alloy (HSLA) steels are truck frames, construction cranes, pipelines, and pressure vessels. You can find their use in the applications where light weight and durability are both the primary KPI of the manufacturing.

Low Alloy Steel vs Stainless Steel

While low alloy steel offers numerous advantages, it’s important to understand how it compares with other steel types. Although both belong to the steel family, low alloy steel and stainless steel have different properties. You can choose the best one that excels in specific conditions.

Here’s the table comparing the key features of both materials.

| Property | Low Alloy Steel | Stainless Steel |

| Alloy Content | <10% | >12% |

| Corrosion Resistance | Moderate | Excellent |

| Strength | High | Moderate to High |

| Cost | Lower | Higher |

When To Choose What: Low Alloy Steel vs Stainless Steel

Confused about what you should pick, low alloy steel vs stainless steel? Well, it totally depends on your purpose and project. Still, here are a few ways through which you can make the best decision.

- When your focus is on one strength and wear resistance, you should go for low alloy steel.

- If your top priority is corrosion resistance, you should choose stainless steel.

- However, if you really want to build a cost-effective project, you should go for low-alloy steel. It is way more affordable than other steel options.

- For manufacturing heavy tools like cranes, bulldozers, or industrial gears, you can choose low alloy steel.

- For projects demanding moderate strength (and where cost is not a high factor), you can pick any option.

- If you are targeting a marine, chemical, or food environment, you must choose stainless steel.

If you’re still confused, you may consult an industrial leader to make the right decision and choose a high-performing steel variant for your project.

Low Alloy Steel vs High Alloy Steel

Both low alloy steel and high alloy steel contain alloy within them. However, it’s the composition that actually makes the real difference.

- High alloy steel contains a significant percentage of alloys (generally >10-12%).

- It has low iron content compared to low alloy steel.

The table given below compares the common features between low alloy steel and high alloy steel:

| Property | Low Alloy Steel | High Alloy Steel |

| Total Alloy Content | < 8-10% | > 10-12% |

| Special Feature | Strength, toughness | Corrosion resistance, special performance |

| Cost | Lower | Higher |

| Machinability | Easier | Harder |

What are the Primary Applications of High Alloy Steel

The common types and applications of high alloy steel include:

- Stainless steel: The most common type of alloy steel. It is cheaper and contains about 10-12% of chromium. It is widely used in utensils, kitchen appliances, and medical implants.

- Tool steel: Known for its hardness, tool steel makes the best cutting equipment.

- Maraging steel: Used in aerospace and defense applications, mainly.

Applications of Low Alloy Steel

Let’s come back to the protagonist of the blog, low alloy steel material. The sections below detail why low alloy steel describes a few of the applications of low alloy steel:

- The strength and durability make it ideal for structural construction projects like buildings, bridges, pipelines, and pressure vessels.

- It is also used to form plates and components of heavy machinery and equipment.

- Low alloy steel material is a key component in the automotive industry. You can find its applications in vehicle bodies like car parts and engine components. A few countries also use it for railways and submarines.

- The oil and gas industry uses low alloy steel for drilling platforms.

- It is also found in power generation and chemical plants. Why? It has corrosion resistance and can handle chemicals (even high temperatures).

Advantages and Limitations of Low Alloy Steel

By now, you might have developed an idea about low alloy steel material and how you can use it. Let’s revisit its pros and cons.

Pros of Using Low Alloy Steel

- It has a high strength-to-weight ratio. Means even lightweight, low alloy steel material can deliver extreme durability. It allows for lighter yet long-lasting structures.

- Unlike high-alloy steel, low alloy steel is affordable. Thus, for large-scale projects, it significantly reduces the cost without compromising the overall performance.

- Steels are all about mechanics and machinability. And low alloy steel knows that. It adapts to all kinds of machines. You can easily weld or give a unique shape to low alloy steel material without spending much on labor or resources.

- And, the best part? You can easily customize low alloy steel to your desired shape and size. It can be easily heated using unique techniques without cracking.

Limitations: When You Should Avoid Using Low Alloy Steel

Despite the advantages, there are a few limitations of low alloy steel material.

- It provides just moderate corrosion resistance. Therefore, in extreme humid or marine environments, low alloy steel material won’t deliver true durability. It may even catch rust attacks in severe conditions.

- The material is highly sensitive to heat treatment. In simple terms, the final properties of low alloy steel depend on precise temperature control during manufacturing.

Conclusion

Engineers proudly choose low alloy steel for its lightweight nature and outstanding performance. It provides the workability of traditional steel with affordability. Low alloy steel has advantages that make it ideal for a range of customer applications where high strength and low cost are important.

Low alloy steel material has the power to manufacture precision-engineered components for futuristic machines. And this makes it a foundation of modern industrial processes. From the majestic skyscrapers around you to the machinery and transport you use every day, there’s a part of low alloy steel redefining the game.

If you have any questions, Hanke Construction Machinery Manufacturing Co., Ltd is here to help you.