Gone are the days when manual tools could keep up with today’s precision demands.

Today, manufacturers use hydraulic CNC press brakes – advanced sheet metal bending machines known for their accuracy and efficiency. This technology is essential in custom sheet metal fabrication, enabling precise bends across various materials and thicknesses.

Whether used in-house or through outsourced CNC metal bending services, these machines are built for performance and consistency.

A hydraulic press brake machine speeds up production and minimizes waste, making it a valuable tool in the competitive fabrication industry.

What is a Hydraulic CNC Press Brake?

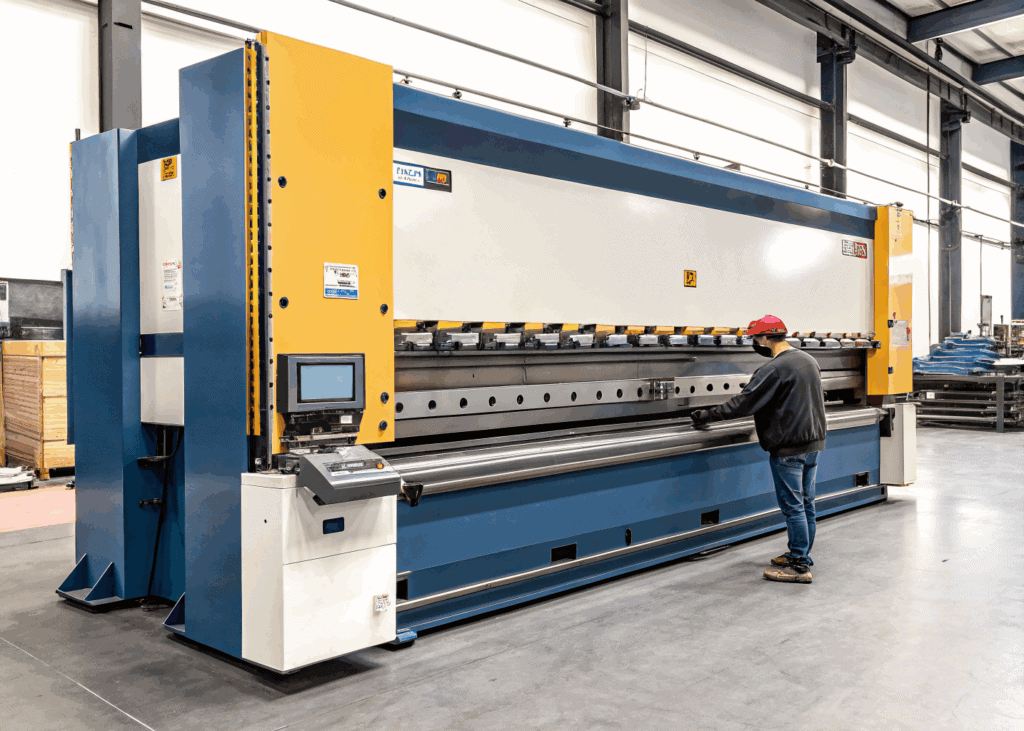

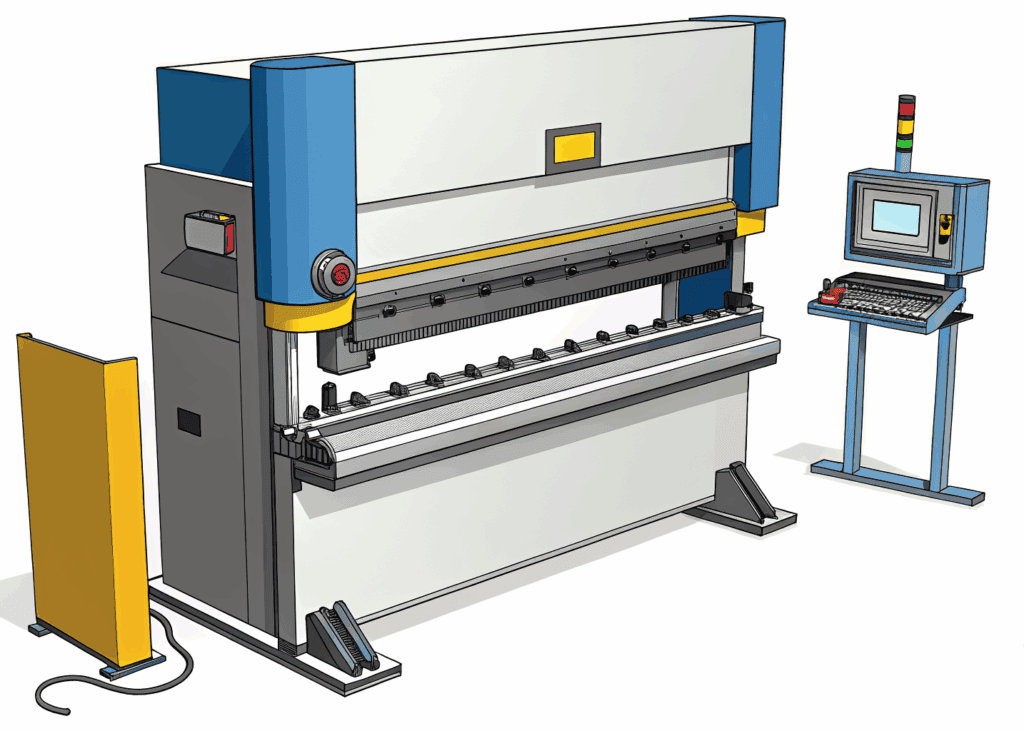

A hydraulic press brake is a type of bending machine used to form sheet metal into precise angles and shapes. It typically consists of a vertically moving ram that applies force to the metal workpiece placed on a die.

A hydraulic CNC press brake machine is a tool used in metalworking to bend sheet metal into specific shapes and angles. It uses hydraulic power and CNC technology, allowing operators to program and perform precise bending operations with great accuracy and consistency.

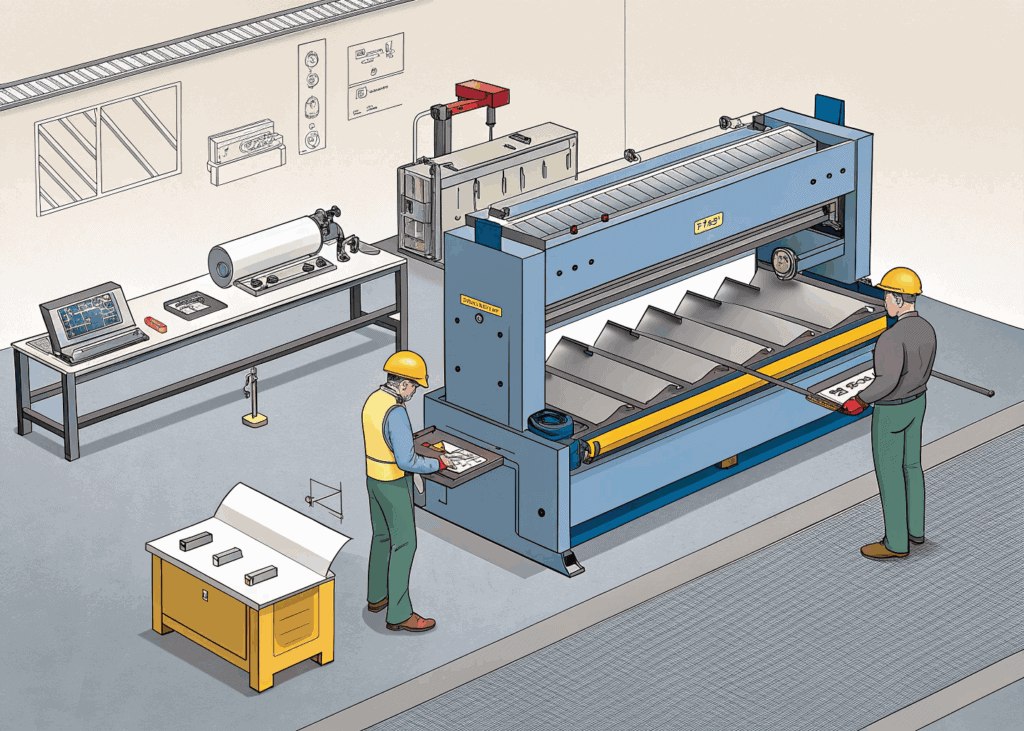

The working principle involves a hydraulic system that applies controlled force to a punch and die setup, bending the metal sheet placed between them. In a press brake, the CNC system controls the machine’s axes, allowing for accurate management of bend angles, lengths, and sequences. This automation reduces human error and increases production efficiency.

Unlike traditional or manual press brakes, which rely on mechanical or purely hydraulic action controlled by the operator’s skill, hydraulic CNC press brakes offer greater consistency and ease of use.

Manual press brakes require repeated manual adjustments, leading to variability in output quality, whereas hydraulic CNC machines provide automated, repeatable bends based on programmed instructions.

A hydraulic CNC press brake machine offers precise bends, ensuring tight tolerances. It’s great for large production runs because it repeats the process consistently. Automation also helps simplify complex tasks, cut labor costs, and reduce waste.

Sheet Metal Bending Machines: Types and Applications

Sheet metal bending is a key metal forming process where force is applied to shape sheet metal into the required form. This technique has been around since ancient times and has evolved greatly with advances in technology.

Sheet metal bending machines come in various types, each suited to different manufacturing needs and production volumes. The most common types include hydraulic, servo-electric, and manual press brakes.

- Hydraulic Press Brakes: These machines use hydraulic systems to apply consistent and powerful force, making them ideal for bending thicker metals and handling heavy-duty tasks. Their CNC integration allows for precise control, repeatability, and automation.

- Servo-Electric Press Brakes: Powered by electric servo motors, these machines offer energy-efficient operation and fast cycle times. They are perfect for medium-thickness materials and applications requiring high speed and precision.

- Manual Press Brakes: These rely on human operation to apply bending force. While less precise and slower than their powered counterparts, manual press brakes remain valuable for small-scale jobs, prototyping, and low-volume production.

Sheet Metal Bending Machine Applications

Sheet metal bending machines are widely used across multiple industries due to their versatility and capability to create complex parts. Key sectors benefiting from these machines include:

- Automotive: Manufacturing body panels, car parts, brackets, and chassis components with tight tolerances and repeatable bends.

- Aerospace: Producing lightweight, durable components from specialized alloys requiring precise shaping.

- Construction: Fabricating structural elements, ductwork, and architectural metal features.

- Machinery and Equipment: Creating parts for industrial machines, agricultural tools, and various equipment requiring durable metal components

Selecting the right sheet metal bending machine depends on factors such as the material type, sheet thickness, production volume, and the level of precision required. Hydraulic CNC press brakes, in particular, offer unmatched flexibility and accuracy, making them a go-to solution in demanding custom sheet metal fabrication environments.

CNC Metal Bending Services: Why Businesses Choose Outsourcing

Outsourcing CNC metal bending services has become a popular strategy for many businesses aiming to optimize costs, access specialized expertise, and improve operational efficiency. Instead of investing heavily in expensive equipment and training, companies can rely on experienced service providers who offer precision bending tailored to specific production needs.

Advantages of outsourcing bending services include:

- Cost Savings: Eliminates the need for upfront investment in hydraulic CNC press brake machines and reduces ongoing maintenance expenses. Businesses pay only for the bending services they require, improving cash flow.

- Access to Expertise: Professional metal bending services bring years of experience, advanced equipment, and skilled operators who ensure high-quality, consistent results, especially for complex or custom bends.

- Increased Efficiency: Outsourcing reduces lead times by leveraging providers’ specialized workflows and advanced machinery, helping businesses meet tight deadlines and scale production as needed.

For example, a manufacturer requiring custom sheet metal fabrication of industrial parts with precise, multi-angle bends might partner with a CNC metal bending service. The service provider uses advanced hydraulic CNC press brakes to produce components that meet strict quality standards, allowing the manufacturer to focus on assembly and finishing.

By outsourcing, businesses can avoid costly trial and error processes, minimize waste, and gain flexibility to respond quickly to changing market demands.

CNC metal bending services offer an efficient, cost-effective solution for companies looking to enhance product quality and production agility without the burden of owning and operating specialized machinery.

CNC brake presses are indispensable in modern custom sheet metal fabrication, offering precision, efficiency, sustainability, and adaptability. As manufacturers continue to embrace automation, the role of CNC technology in press brakes will only expand, driving advancements in productivity and quality.

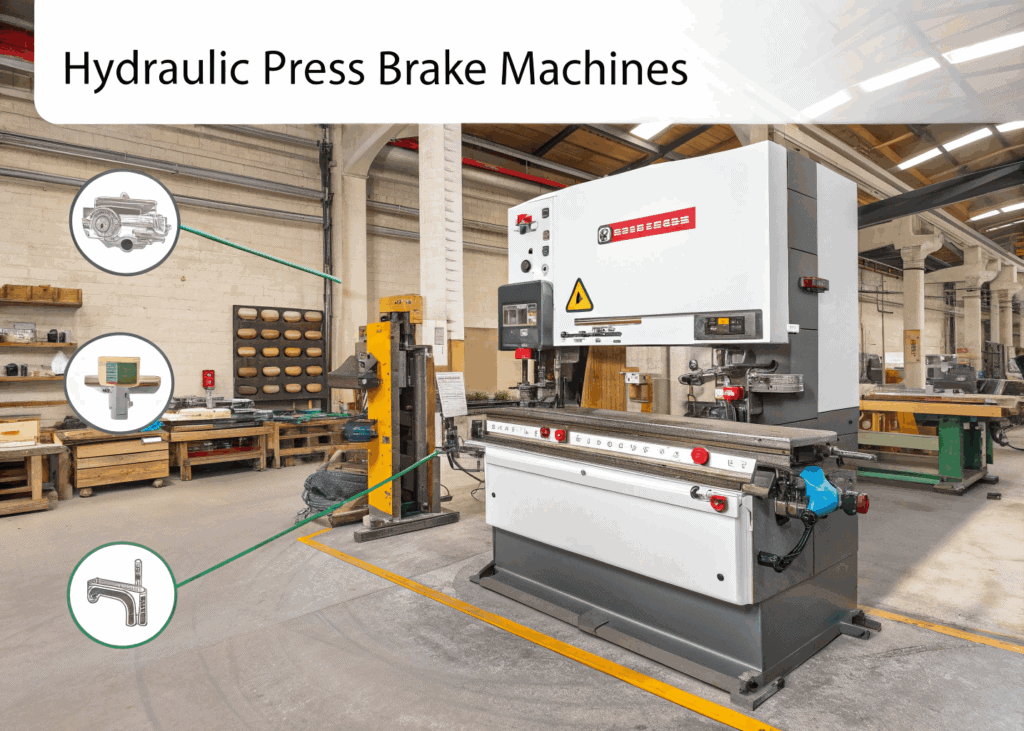

Hydraulic Press Brake Machines: Features That Matter

When investing in a hydraulic press brake machine, manufacturers must evaluate several key features to ensure the equipment aligns with their production requirements. These machines are critical in delivering high precision bending across various materials, and selecting the right configuration can directly impact performance, efficiency, and output quality.

Here are the core features that matter most to buyers:

- Tonnage Capacity:

The tonnage determines the amount of force the press brake can apply during bending. Choosing the correct tonnage is essential based on material type and thickness. Underpowered machines can not handle thicker metals, while overpowered units may waste energy and increase costs. - Working Length:

The bed or working length defines the maximum size of sheet metal the machine can bend. Manufacturers must consider part dimensions and bending applications to choose a hydraulic press brake machine with an appropriate bed size. - Control System / CNC Interface:

Modern hydraulic press brake machines are equipped with CNC (Computer Numerical Control) systems that allow for the programming of bend sequences, angles, and depths. A user friendly interface ensures easier setup, while advanced systems enable multi-axis control, real time feedback, and error minimization. - Precision Bending Capabilities:

High-precision bending is a key advantage of hydraulic press brakes. CNC integration ensures consistent results, tight tolerances, and the ability to reproduce complex bends across large production runs. - Automation and Customization Options:

Advanced machines offer automation features such as back gauge positioning, crowning systems, and tool change capabilities. These features reduce manual input, speed up operations, and support complex geometries with minimal error.

Selecting the right hydraulic press brake machine is not just about size or power, it is about matching the machine’s capabilities to your production goals. With the right specs, businesses can achieve better accuracy, reduce waste, and significantly improve overall manufacturing efficiency.

Custom Sheet Metal Fabrication Solutions: Meeting Unique Industry Needs

Custom sheet metal fabrication plays a crucial role in industries where standard parts simply would not cut it. Every project has its own set of specifications, whether it is a unique shape, specialized material, or strict tolerance. That is where custom fabrication shines.

From the initial design stage to the final product, fabricators work closely with engineers and manufacturers to ensure that the metal components are tailored exactly to the application. This includes choosing the right metal (aluminum, stainless steel, etc.), deciding on appropriate thickness, and incorporating features like cutouts, bends, or mounting points.

Building a prototype for a new device or producing a large batch of enclosures, custom sheet metal fabrication adapts to the technical and aesthetic demands of the job.

From Prototyping to Mass Production

One of the biggest advantages of custom sheet metal fabrication is its flexibility across production stages.

- In the prototyping phase, fabricators can quickly produce one-off parts to test fit, function, and performance.

- As the design matures, the same fabrication processes can be scaled up for mass production, using CNC machines, laser cutting, and automated assembly systems to maintain precision and consistency.

This smooth transition from prototype to production saves time, reduces errors, and supports faster time to market.

Industries That Rely on Custom Sheet Metal Fabrication

Alt Tag: Industries That Rely on Custom Sheet Metal Fabrication

Many industries depend on custom sheet metal fabrication to meet specific functional, regulatory, and durability needs. Common sectors include:

- Electronics: Custom enclosures, component brackets, and heat sinks for devices and systems.

- Transportation: Precision metal parts for vehicles, such as interior panels, mounts, and structural supports.

- Medical: Fabricated metal components for diagnostic equipment, surgical tools, and housings that meet hygiene standards.

- Telecommunications: Racks, chassis, and cable management systems for network infrastructure.

- Industrial Equipment: Durable machine parts, safety guards, and supports for manufacturing environments.

Each of these industries requires strict quality control and custom solutions that can not be achieved with off the shelf components.

Why Choose Our CNC Bending & Fabrication Services

At Hanke Construction Machinery Manufacturing Co., Ltd, we offer expert CNC bending and fabrication services tailored to your needs. Our skilled team uses advanced equipment to ensure precise and consistent results for every project.

We work with materials such as steel, aluminum, and stainless steel, producing parts for construction machinery, mining, rail transit, and petroleum equipment. Some of our key products include shafts, sleeves, pump truck accessories, crawler crane joints, and shovel teeth for excavators.

Our factory is equipped with advanced inspection tools like a German SPECTRO optical instrument and coordinate measuring machines, ensuring every part meets strict quality standards. We are also certified in quality, safety, and environmental systems.

Trusted by clients including the XCMG Group, we aim to deliver consistent quality, competitive pricing, and excellent service.

We also hold industry certifications that demonstrate our commitment to quality and reliability.

Contact us today to request a quote and learn how we can support your next project.

Frequently Asked Questions (FAQs)

What is the difference between a press brake and a bending machine?

A press brake is a type of bending machine specifically designed to bend sheet metal into precise angles and shapes using a punch and die setup.

While all press brakes are bending machines, not all bending machines are press brakes. Press brakes, especially hydraulic CNC press brakes, offer higher precision and automation compared to simpler bending machines.

How accurate is CNC sheet metal bending?

CNC sheet metal bending provides very high accuracy, often within tight tolerances of ±0.1 mm or better.

The computer numerical control system allows for consistent and repeatable bends, reducing human error and ensuring precision across large production runs.

What materials can be bent with a hydraulic CNC press brake?

Hydraulic CNC press brakes can bend a wide range of metals including steel, stainless steel, aluminum, brass, and copper.

Their powerful hydraulic systems enable bending of various thicknesses and material strengths, making them versatile for many fabrication needs.

What industries use custom sheet metal fabrication?

Custom sheet metal fabrication is used across many industries such as electronics, transportation, medical, telecommunications, and industrial equipment manufacturing.

These industries rely on precise, durable, and tailored metal parts that meet strict quality and functional requirements.

Conclusion

Hydraulic CNC press brakes and advanced sheet metal bending machines have transformed the way industries approach metal fabrication. From precision bending and high repeatability to the flexibility of handling various materials, these machines are essential in today’s manufacturing environments.

At Hanke Construction Machinery Manufacturing Co., Ltd, we combine cutting-edge equipment with expert CNC metal bending services to meet the demands of custom sheet metal fabrication. Whether you need prototyping support or large scale production, our team is ready to deliver quality, accuracy, and efficiency.

Contact us today to request a quote for your next CNC metal bending or custom fabrication project. Let’s bring your designs to life with precision and reliability.