The metal casting industry is very important. It helps make many things, like car parts and art. People have been using this method for many centuries, and it continues to improve with time..

The industry is expected to grow a lot. By 2033, it could reach USD 325.69 billion. New technology is driving this growth. There is also more demand from industries like cars and construction. Additionally, a focus on being eco-friendly is helping the industry grow.

In this article, we will explain how metal casting works. We will also talk about the different ways it is used and how companies like Huasuma are helping the industry.

What is Metal Casting?

Metal casting is a smart and useful way to make things. It has been used for thousands of years. The technique involves pouring melted metal into a mold, where it cools and forms a solid object.

Metal casting is mainly used to create firm metal items for a wide range of applications. It’s a way to make objects quickly and efficiently, especially when they need to be strong or last a long time.

Metal casting started a long time ago, all the way back to 3200 BCE, when people first used it to make tools and artwork. The Bronze Age was an important time because it was when people discovered bronze. Bronze made metal casting more useful. People used it to make weapons and beautiful decorations.

Over the years, metal casting made many things. It created sculptures, jewelry, weapons, and tools. It became an important way to make things that were both artistic and useful. During the Industrial Revolution, people invented new metal casting methods. Methods like sand casting and die casting helped make things in large amounts.

Our cast products are undergoing secondary processing #cncmill #cncsoftware #manufacturing #

Applications of Metal Castings

Many industries use metal casting to create things we use every day. Let’s look at some of the key industries that rely on metal casting.

Automotive Industry

Metal castings are important in the automotive world. For example, car engines and transmission systems are made with metal castings. These parts need to be strong and durable, and metal casting allows manufacturers to make these parts in the right shape and size.

Construction

In construction, metal castings are used to create strong and durable support structures. These structures help hold up buildings and bridges, making sure they’re safe and stable. Cast metals are perfect for construction because they are strong and can handle heavy loads.

Artistic Uses and Sculptures

Metal casting isn’t just for tools and machines. It’s also used by artists to create beautiful sculptures. Artists often use metals like bronze to make intricate and detailed art pieces that last a long time.

Household Items

People make common household items like door handles, lamp posts, and faucets using metal casting. They use cast metal because it’s strong and can be molded into the right shape for everyday use.

Small Production Shops

Small production shops also use metal casting. It’s a fast way to make parts in small batches or create custom orders. Metal casting helps save time and is a good option for quick production.

Types of Metal Casting Processes

Metal casting can be done in various ways, and each method has its own advantages based on what it’s used for. Below are two common types you should be familiar with:

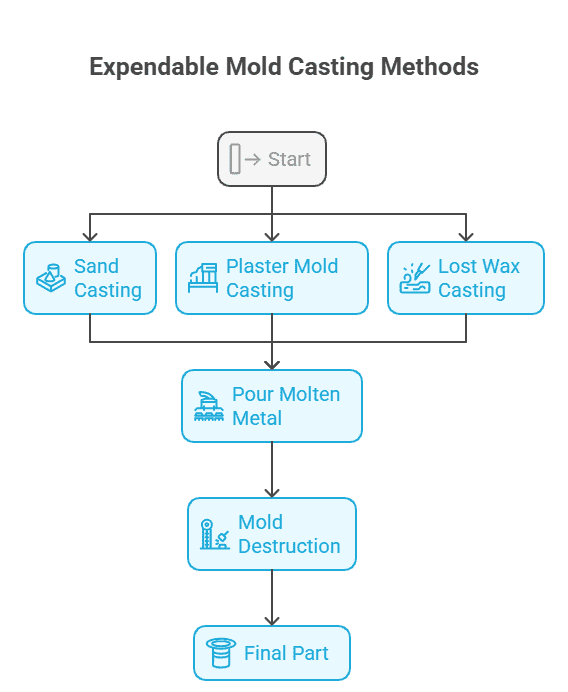

Expendable Mold Casting

In expendable casting, a single-use mold is used to shape the molten metal into a specific part. These molds are usually made from sand, plaster, or ceramic, which are easy to shape. This method is great for making parts with detailed shapes and is also cost-friendly. But since the mold gets broken after one use, it’s not a good choice for making lots of the same parts.

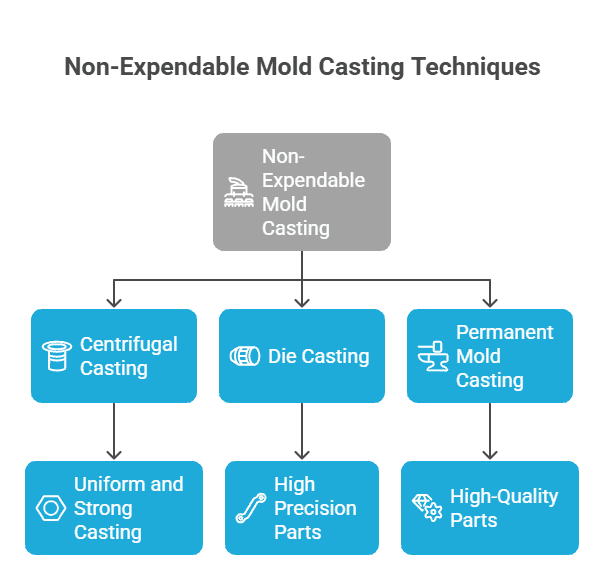

Non-Expendable Mold Casting

In permanent mold casting, also called non-expendable casting, strong molds are used many times to make parts. These molds are built from heat-resistant materials like iron, steel, or graphite. Before pouring in the melted metal, the mold is heated. Once the metal cools and hardens, the mold is opened to take out the final product.

Expendable Mold Casting Methods

Expendable mold casting involves different methods where the mold is broken after the metal is poured. These methods are commonly used because they allow for greater design freedom and can handle complex shapes. Let’s take a look at some of the most popular methods.

Sand Casting

One of the most widely used and earliest metal casting techniques is sand casting. It’s cost-effective and flexible. This method uses sand to build the mold that shapes the metal. The mold is destroyed after the metal is poured and cooled. It works well for casting both big and small objects, including engine blocks and sturdy parts. Parts made from sand casting can weigh up to 2,700 kg (about 6,000 pounds).

Plaster Mold Casting

Plaster mold casting uses plaster of Paris to make the mold. It works well for creating small parts with fine details. This method is only suitable for metals that melt at lower temperatures, such as brass or aluminum. It’s a low-cost way to produce detailed pieces with smooth surfaces.

Lost Wax Casting

This method is ideal for creating finely detailed items such as small sculptures and jewelry. It begins with shaping the object in wax, which is then covered in a heat-resistant material like clay. Once set, the wax is melted out, leaving an empty mold that is filled with molten metal to form the final design.

Non-Expendable Mold Casting Techniques

Non-expendable mold casting uses molds that can be reused multiple times. These molds are made from strong materials that can withstand many cycles of pouring molten metal. Let’s look at some common non-expendable mold casting techniques.

Centrifugal Casting

Centrifugal casting involves pouring hot metal into a rotating mold. The spinning motion pushes the metal outward, which helps create a uniform and strong casting. This method is often used to make pipes, tubes, and other circular parts. The spinning helps the metal fill the mold evenly, ensuring the casting has no weak spots.

Die Casting

Die casting helps create components with high precision. In this method, liquid metal is pushed into a metal mold using high pressure. This technique allows manufacturers to create complex shapes with a smooth finish. Die casting is used in the automotive industry. It helps make parts like engine components and small, detailed pieces for electronics.

Permanent Mold Casting

Permanent mold casting uses a metal mold that can be reused many times. This method is great for making high-quality parts that need to be produced in large quantities. The mold is often made from steel or iron and is used to create items like engine blocks, cylinder heads, and other parts that need to be strong and durable.

The Metal Casting Process Step-by-Step

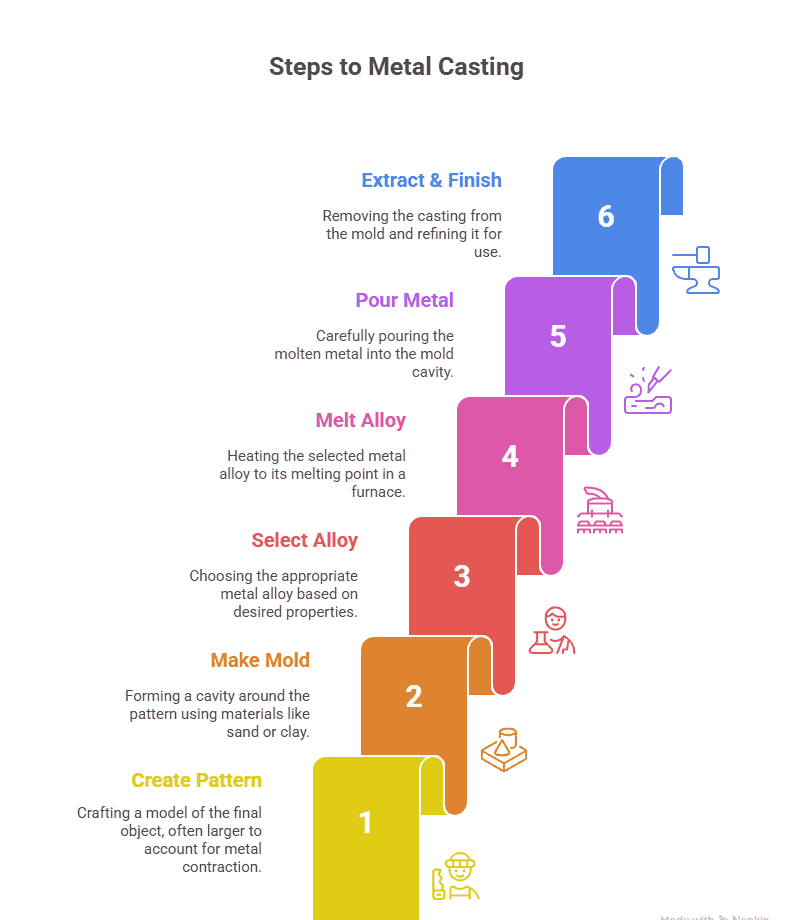

Metal casting involves several important steps. Let’s break down each step so you can understand how it works from start to finish.

1. Creating the Pattern

The first step is making a pattern of the item to be cast. Materials such as wax, plastic, wood, or metal are commonly used to form the pattern. The pattern is usually made larger than the final size of the object because metal contracts as it cools. This process ensures that the final casting will be the right size.

2. Making the Mold

After the pattern is finished, a mold is created by surrounding it with substances like clay or sand. This material hardens to form a shape that will hold the molten metal. The mold must be strong enough to withstand the heat of the molten metal.

3. Selecting the Metallic Alloy

Choosing the right metal for casting is very important. Different metals have different properties, like strength and resistance to rust. For example, steel is strong and used for construction, while aluminum is lightweight and good for things like airplane parts. The alloy (a mixture of metals) is chosen based on what the final product will be used for.

4. Melting the Alloy

After selecting the alloy, it’s melted in a furnace. The metal is melted by raising it to a very high temperature. The right temperature is important because different metals melt at different points. For example, aluminum melts at around 660°C, while steel requires a much higher temperature.

5. Pouring the Molten Metal

After melting, the metal is gently transferred into the prepared mold. This step must be done carefully to avoid spilling or causing defects in the final product. The liquid metal flows into the mold and forms the exact shape of the design.

6. Extracting and Finishing the Casting

After the metal has cooled and solidified, the mold is removed, and the casting is taken out. The casting may have rough edges or imperfections, so it is cleaned and polished. This step ensures the final product is smooth and ready for use.

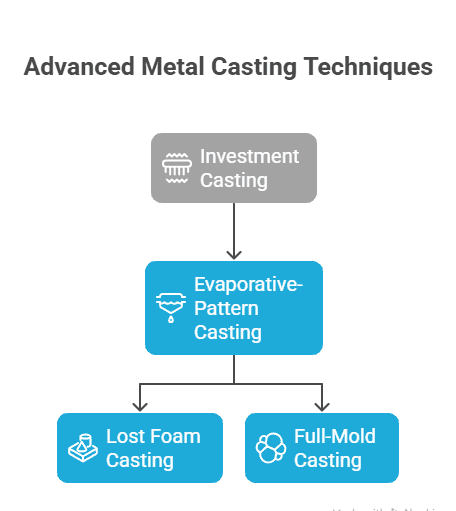

Advanced Metal Casting Techniques

Advanced metal casting techniques provide more precise and detailed castings. These methods are often used for special parts or when you need high quality.

1. Investment Casting

Investment casting, sometimes called the lost wax method, helps make very precise and detailed parts. It’s commonly used for things like jewelry and airplane parts. The process starts with making a wax model of the item. This wax model is then covered with a strong material, such as clay. Once it hardens, the wax is melted out, leaving a hollow mold. Hot metal is then poured into this mold to form the final object. This method works well when small, detailed parts are needed.

2. Evaporative-Pattern Casting

Evaporative-pattern casting uses a pattern made from foam. When molten metal is added, the foam pattern disappears, creating a mold for the casting. This method is faster than investment casting. It’s used for parts that don’t need as much detail. The foam evaporates completely, leaving a perfect space for the molten metal.

3. Lost Foam Casting

This method, called lost foam casting, uses a foam pattern that disappears during the pouring process. The foam is coated with a material like sand and then heated. As the molten metal is poured into the mold, the foam pattern evaporates, leaving behind a metal part in the shape of the foam pattern. Lost foam casting is used for large parts and is often more cost-effective than investment casting.

4. Full-Mold Casting

Full-mold casting is another type of evaporative-pattern casting. It uses a foam pattern made of polystyrene.Sand is packed around the foam model to form the casting mold. When the molten metal is poured, the foam evaporates. This leaves a mold for the casting. This method is used for making larger and simpler parts. It is often used for making engine blocks and other heavy-duty items.

How Huasuma Overcomes Metal Casting Challenges

Metal casting is important for making strong and durable parts that we use every day, like car parts, tools, and building materials. Sometimes, it’s hard to find the right parts that fit perfectly or last a long time. This is how Huasuma can help:

- High-Quality Parts: Huasuma uses the best tools to make sure every part is made correctly. They check every part to make sure it’s strong and works well.

- Different Materials: Whether you need parts made of iron, steel, or aluminum, Huasuma can make it. They use many different types of metal to make sure the part is just right for your needs.

- Custom Solutions: Huasuma listens to what you need and makes custom parts just for you. Whether you need a small or large part, they can help you get it right.

- Fast and Reliable: Huasuma works quickly and carefully, so you get your parts on time and know they’ll work as expected.

Conclusion

Metal casting is an important way to make many things we use every day. It turns liquid metal into solid shapes. This can be used to make car parts, buildings, or even art.

There are different ways to do metal casting. Some ways are better for making big parts. Others are good for making smaller or more detailed parts. No matter the method, metal casting is used in many industries like cars, buildings, and art.

Now you know how metal casting works and why it’s so useful. If you want to learn more or need help with a project, Huasuma is here to assist you. Feel free to reach out for more information or to discuss your specific metal casting needs.

FAQs

Let’s go over some common questions people have about metal casting to make things clearer.

1. What are the common defects in casting?

Metal casting is a complex process, and sometimes things go wrong. Common defects include air bubbles, cracks, or uneven surfaces on the casting. These defects can happen if the metal cools too quickly, the mold isn’t made properly, or the metal is poured too fast.

2. How does metal casting differ from forging?

Casting and forging are two ways to shape metal, but they use different processes. Casting involves melting the metal and pouring it into a mold to form a shape. In forging, the metal is heated and then shaped by hammering or pressing. Forged pieces are often stronger because the metal is tightly packed, while casting is better for making shapes with lots of detail.

3. Is casting cost-effective for small batches?

Casting is usually cheaper when making a lot of parts because the molds can be used again. But if you’re making only a few parts, using sand casting can be cheaper because it doesn’t need expensive molds. Even though it might cost more for small batches, casting can still be a good choice depending on how big or complicated the parts are.