What is Lost Wax Casting?

Also referred to as investment casting by some, lost wax casting is a metal casting procedure where manufacturers pour a molten metal into a mold created from a model of wax thereby resulting in duplicate objects, also known as lost wax casting parts.

Lost wax casting is an old procedure, having been around since the third millennium BC. Today, this method is still in use, with manufacturers arguing that it’s flexible, allowing them to develop complex, intricate designs without the need to account for shrinkage or post-process finishing of investment casting products.

In this guide, you’ll get to know almost everything about lost wax casting. The guild will range from how low wax casting works, to the common materials used, the benefits of lost wax casting, and why you need to choose us at Hanke Construction Machinery Manufacturing , Inc. for your entire lost wax casting services.

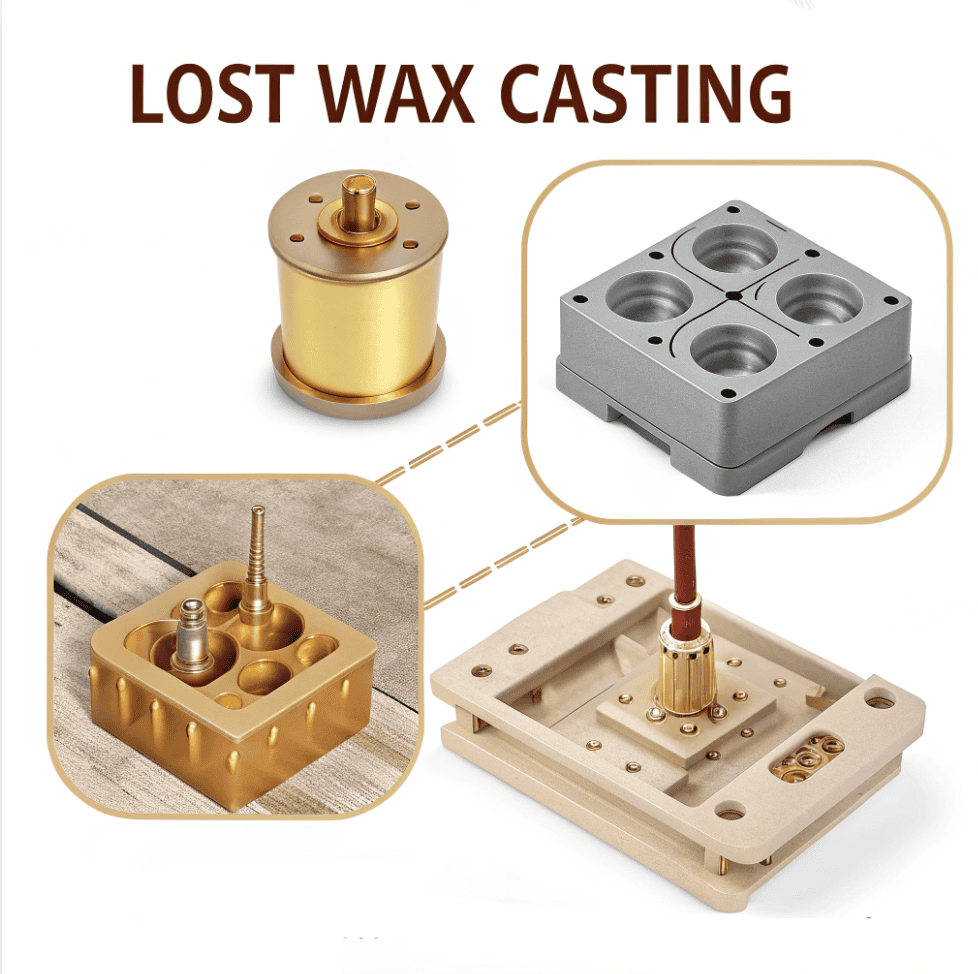

How the Lost Wax (Investment) Casting Process Works

The basic lost wax casting procedure isn’t complicated as you may imagine. First, you need to create a wax model of your desired object or casting parts through either carving or 3D printing. Thereafter, you need to wax the model, coating it with a heat-resistant material to create a mold around it.

After creating your mold, you need to burn the wax to create a hollow cavity in the mold. Now, you need to pour the molten metal into the hollow cavity to fill the space where your wax used to be. Once you finish this process, let the metal cool and solidify before breaking the mold to reveal the cast metal object or casting parts.

Benefits of Lost Wax Casting Over Other Methods

For engineers and manufacturers alike, lost wax casting has some benefits worth noting. The first being few limitations or restrictions to the types of metals to use during the process. Engineers and manufacturers can use an array of metals that fit their investment casting products.

Another benefit is that it requires less manpower. It has a low post-processing, uses few resources and has a fast turnaround. Additionally, the size range begins with something miniature as a dental implant. Manufacturers can then scale to include casting parts that are intricate and detailed such as engine parts that weigh thousands of pounds.

Common Materials Used

Even though you can use plenty of materials in your lost wax casting service, some of the most common materials preferred by many include stainless steel, bronze, aluminum, and brass. Others include alloys such as nickel-chrome and cobalt-chrome.

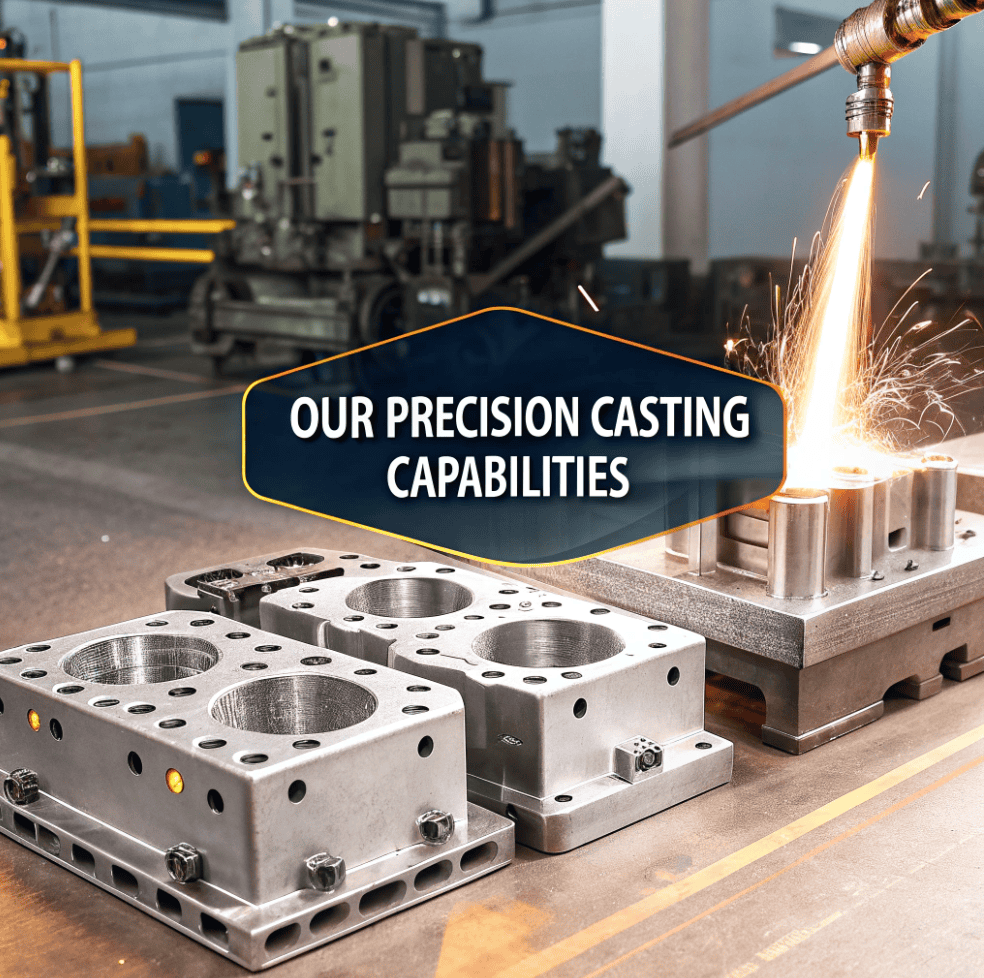

Our Precision Casting Capabilities

We at Hanke Construction are a top lost wax casting service provider, having opened for business in 1993. Having been in business for more than two decades and counting, you can count on us for your entire investment-casting project. Some of our capabilities include the following:

Tolerances & Quality Standards

Tolerance is vital in lost wax casting as it influences the functionality and accuracy of the final cast part. We at Hanke Construction understand the importance of tolerances and quality standards of our lost wax casting parts.

As a top lost wax casting service provider, we can envisage your measurement data. We have a big team highly qualified in advanced metrology and 3D software. We are able to come up with accurate measurements that you cannot find in some casting facilities.

We also use Advanced Product Quality Planning (APQP) to ensure we manufacture high-quality casting parts to meet customer demands.

Surface Finishes & Complex Geometries

We at Hanke Construction excel at producing some of the most complex geometries alongside detailed components. We’ve been in business for over two decades, learning and improving on how to come up with smooth surface finishes on our entire casting parts.

At Hanke Construction, we understand that achieving complex shapes and sizes with high precision and consistency is one of the biggest challenges that manufacturers face. However, regardless of the shape of your product, rest assured of precision casting parts with smooth surface finishes.

Tooling & Mold Making Process

Tooling and mold making are vital in lost waxing. This is because they impact the precision, accuracy, and the quality of the final cast product. This ensures that there’s consistent replication of efficient production and intricate designs or casting parts.

Our lost wax casting services utilize several tools for the production of mold waxes. However, we mostly use high-grade aluminum alloy that serves as a mold for wax. We handle different casting processes and therefore employ proper tooling to create desired cast parts.

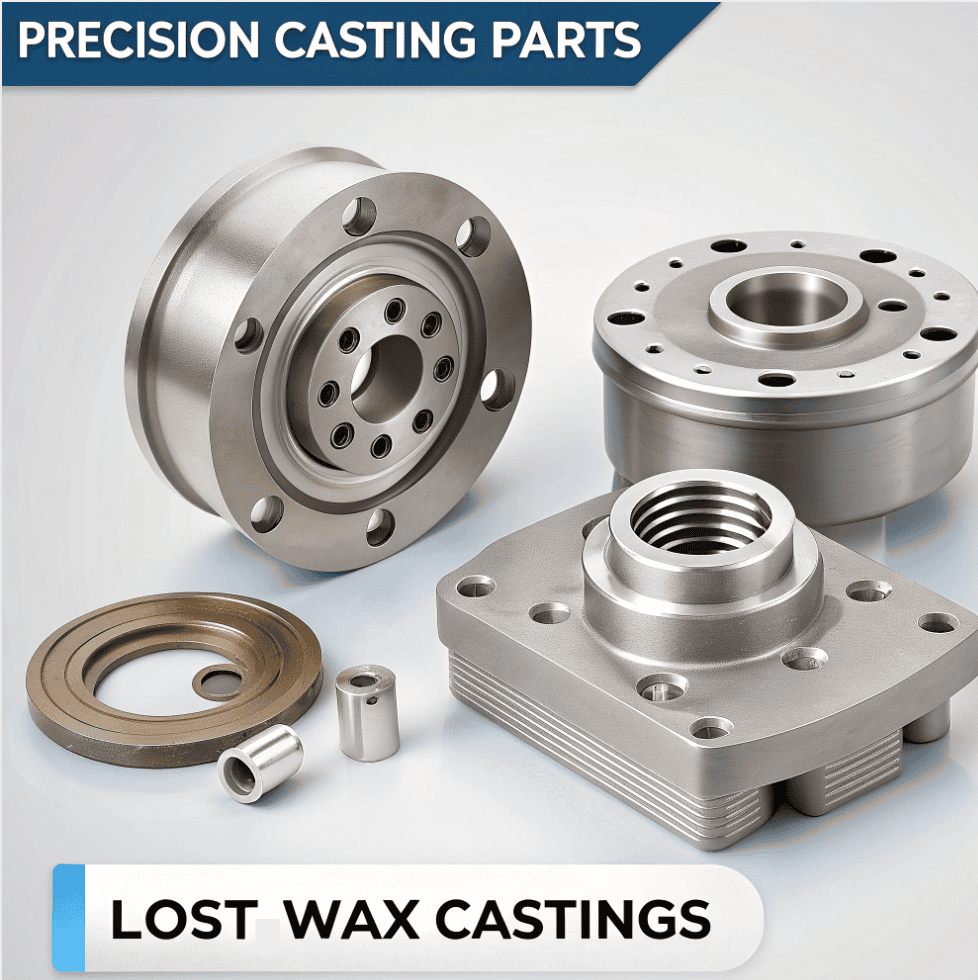

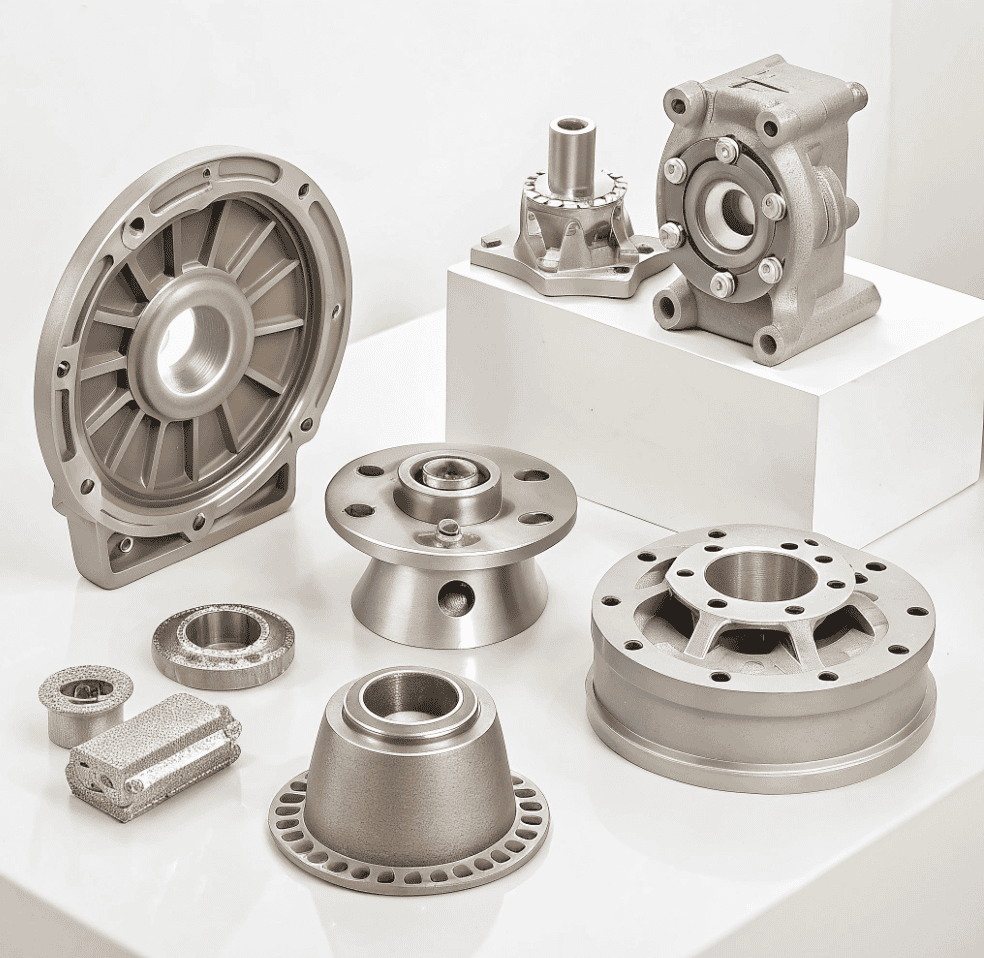

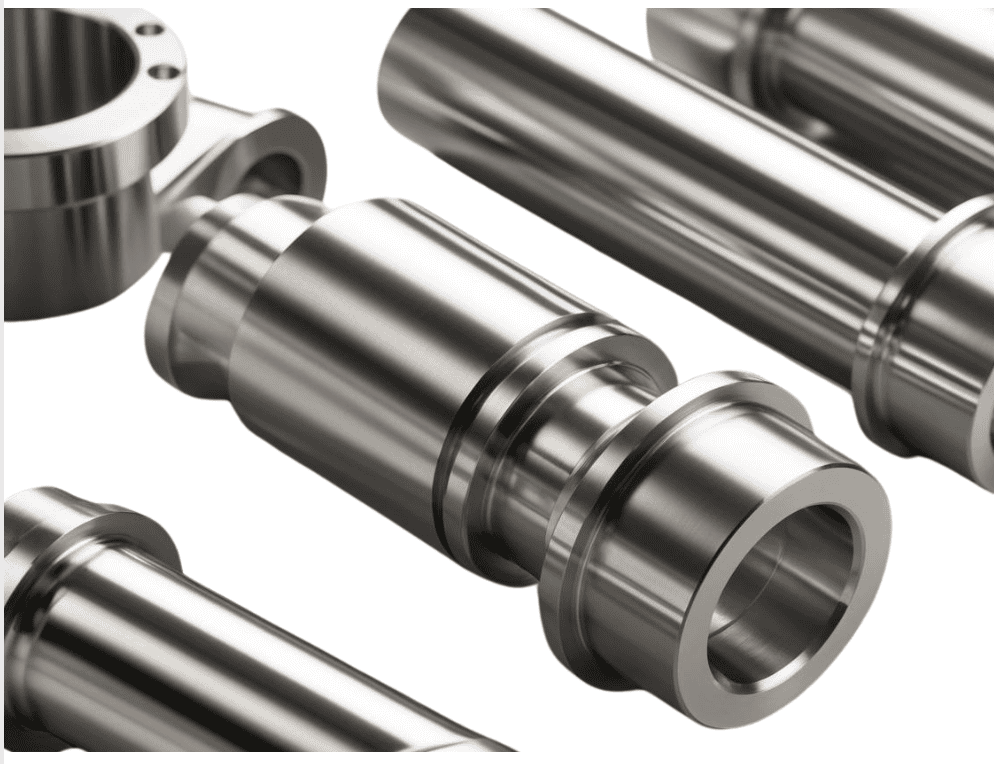

Types of Casing Parts We Produce

At Hanke Construction, our lost wax casting service is able to manufacture plenty of components used in several industries. We are able to create a wide range of high quality components and parts for different sectors. Some of the casting parts we produce include the following:

Custom Industrial Components

As a bespoke lost wax casting service provider, we are able to create custom industrial components for almost all kinds of industries. We produce high quality custom industrial components to cater to unique needs of individual customers.

With our customizable specifications, we’re able to meet customers’ specific parameters such as material, size, color, and functionality, thereby allowing a high degree of personalization. Our casting parts clearly stand out from the rest.

Automotive & Aerospace Parts

Lost cast waxing plays a vital role across the automotive and aerospace industries. The automotive industry heavily depends on investment casting products. We are experts in the field with the ability to manufacture fuel systems, engine components, and suspension systems, to mention but a few.

The aerospace industry heavily relies on us for the manufacture of crucial casting parts such as bearings, jet engine airfoils, turbine exits, flaps, and other critical engine components that are integral to several parts of these vehicles.

Medical & Marine Applications

The exactness of our investment is ideal for regulatory specifications needed for products in the medical field. Such include investment casting products such as forceps, surgical instruments, and implants, to mention a few.

Parts required for marine sector produced via lost wax casting also have to exhibit some specific characteristics to withstand harsh conditions. At Hanke Construction Machinery Manufacturing, we are able to manufacture several marine casting parts such as slip linkages, valve brackets, locking levers, and propellers, among others.

Why Choose Us for Lost Wax Casing Services?

When it comes to lost wax casting services, there’s nothing more unpleasant than sourcing your components from unprofessional manufacturers. Since you’re paying them using your hard-earned funds, you need to ensure that you get high quality casting parts in return.

Have you been painstakingly looking for a qualified, experienced, and reliable lost wax casting manufacturer? If you are here, count yourself lucky. You may want to make us your number one choice for your entire lost wax casting services, especially due to the following reasons:

In-House Tooling and Rapid Prototyping

Our in-house tooling coupled with rapid prototyping is arguably one of the big reasons to choose our lost wax casting services. With this, we offer a streamlined approach to lost wax casting, thereby allowing us to create prototypes quickly and even tooling for low-volume manufacturing.

With our in-house tooling, we’re able to create plastic or other any other tooling to come up with wax patterns, thereby reducing costs and lead time on your casting parts. Our rapid prototyping utilizes 3D printing to create wax patterns easily and directly from a CAD design.

ISO Certifications & Quality Assurance

Another major reason why you may want to source all your lost wax casting parts from us is the fact that we’re an ISO-certified casting firm. In the years that we’ve been in business, we have ensured not to compromise on quality.

We are proud to inform you that our quality standards have been recognized and managed to receive ISO certification, an international certificate met under our strict guidelines for quality assurance, especially in material, casting parts production, installation, and service provision.

As briefly mentioned earlier, we use Advanced Product Quality Planning to efficiently understand the product and its intended application and translate the knowledge to manufacturing high quality investment casting products. With us, rest assured of high quality, better looking products.

Global Shipping & Competitive Pricing

Regardless of anywhere you are across the globe, you can be sure to receive your lost wax casting parts at the agreed time. Thanks to our global shipping strategies, we at Hanke Construction Machinery Manufacturing are committed to providing our clients rapid turnaround times without having to compromise on quality.

To build trust in our reliable global shipping, we focus on several crucial factors such as transparent communication, reliable tracking, and a good record of safe and timely deliveries. We ensure that all your casting parts arrive at your desired destination at the agreed time.

We also offer some of the most competitive rates compared to many of our competitors. With our state-of-the-art manufacturing firm, some of the latest technology, and an efficient workforce management, we easily achieve competitive production costs to help our customers avoid unnecessary costs on their casting parts.

Investment Casting Products Gallery

Regardless of your investment casting needs, we at Hanke Construction Machinery Manufacturing are ready to meet your demands within the shortest time possible. As stated earlier, industries that continue to benefit from our lost wax casting services encompass aerospace, marine, robotics, medical, and automotive sectors, to mention a few.

Case Studies or Examples

Some of the lost wax casting parts available at our stores include fuel pumps, medical castings implants, injector clamps, oil supply bends, locking levers, and dental prosthetics to mention a few.

Material & Finish Specifications

At Hanke Construction, we offer a wide range of materials and finish specifications on our casting parts, including several metals such as brass, stainless steel, bronze, aluminum, and nickel-based alloys. We prefer stainless steel due to its corrosion resistance and durability. We also use aluminum, mostly because it’s lightweight and a versatile option.

Brass is also an ideal material and we prefer it due to machinability, not forgetting bronze for its durability and strength. Nickel-based alloys aren’t corrosive, offer exceptional heat, and ideal for high-temperature casting parts.

For our casting parts finishes, we heavily rely on Polishing to create smooth, mirror-like surfaces. We also employ Bead Blasting to create a textured finish, and Anodizing finishes to create a protective oxide layer, especially on aluminum lost wax parts.

FAQs about Lost Wax & Investment Casting

What’s the difference between lost wax and investment casting?

Lost wax casting and investment casting are largely synonymous, and refer to the same procedure of creating a mold from wax patterns then casting a metal into it.

What are typical lead times?

Typical lead times for lost wax casting parts differ depending on manufacturers, production volume, and tooling requirements. However, most of them range from 4 to 8 weeks.

Can we help with design optimization?

Absolutely! At Hanke Construction Machinery Manufacturing, we can help you with design optimization to refine the design of the model or wax pattern to ensure accurate casting and efficiency on your casting parts.

Request a Quote or Consultation Today

How to Get Started

High-quality lost wax casting service is one of our offerings here at Hanke Construction Machinery Manufacturing. Having been in business for over two decades, you can rely on us for lost wax casting products that meet your needs. Lost wax casting is our specialty, and known globally for our extraordinary precision and attention to detail.

You can trust Hanke Construction Machinery Manufacturing to bring your entire vision to life, all with exceptional accuracy alongside unmatched craftsmanship through lost wax casting services. Everything is easy with us. All you need to do is to contact us for any lost wax casting needs or request a quote for your project.

What Info to Provide

At Hanke Construction Machinery Manufacturing, you can be sure to find accurate and up-to-date information on our lost wax casting capabilities, the types of metals we use, the complexity of the casting parts to produce, certifications, quality standards, lead times, and volume capabilities, to mention a few.

Wrap Up

Are you looking for top-quality investment lost wax casting services for high precision, superior surface finishes, intricate designs, along with the capability of easily handling a wide range of sizes and materials? If that’s the case, look no further than Hanke Construction Machinery Manufacturing. With our experience and expertise, rest assured of high quality lost wax casting parts within a fleeting period.