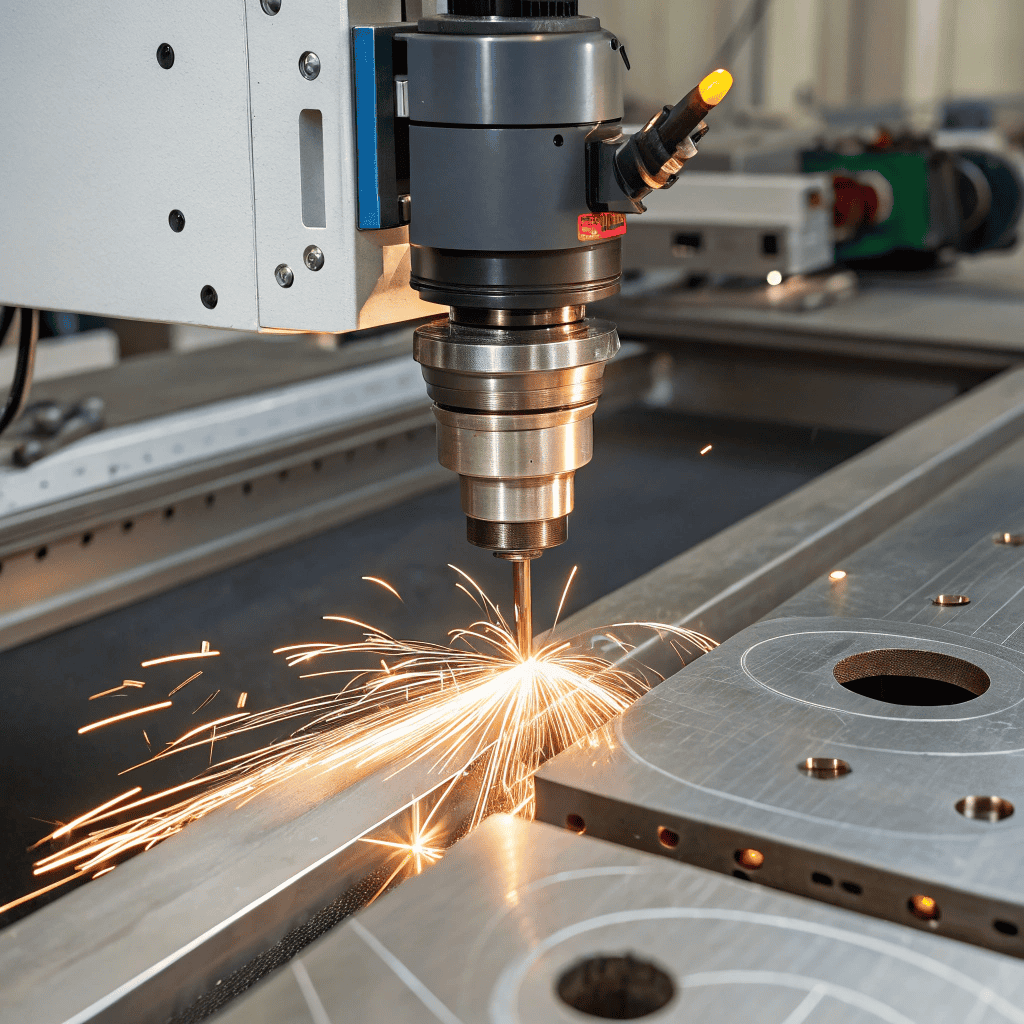

High-speed and high-precision are the new manufacturing environment. And laser machining is setting new standards for accuracy, repeatability, and efficiency. From micro-drilled holes in medical devices to precision cuts in aerospace turbine blades, laser positioning systems are powering next-generation production lines.

Unlike traditional mechanical methods, laser cutting and drilling offer non-contact, programmable, micron-accurate processes, all essential for industries demanding tight tolerances, low thermal distortion, and reduced material waste.

With the rise of automation, AI integration, and adaptive optics, manufacturers now have access to unmatched capabilities for complex, high-throughput operations.

In this simple guide, I will tell you the core technologies, industrial applications, and how to choose the right laser positioning system.

And also, I highlight the difference between laser cutting vs. drilling, and future trends that are shaping high-precision laser machining.

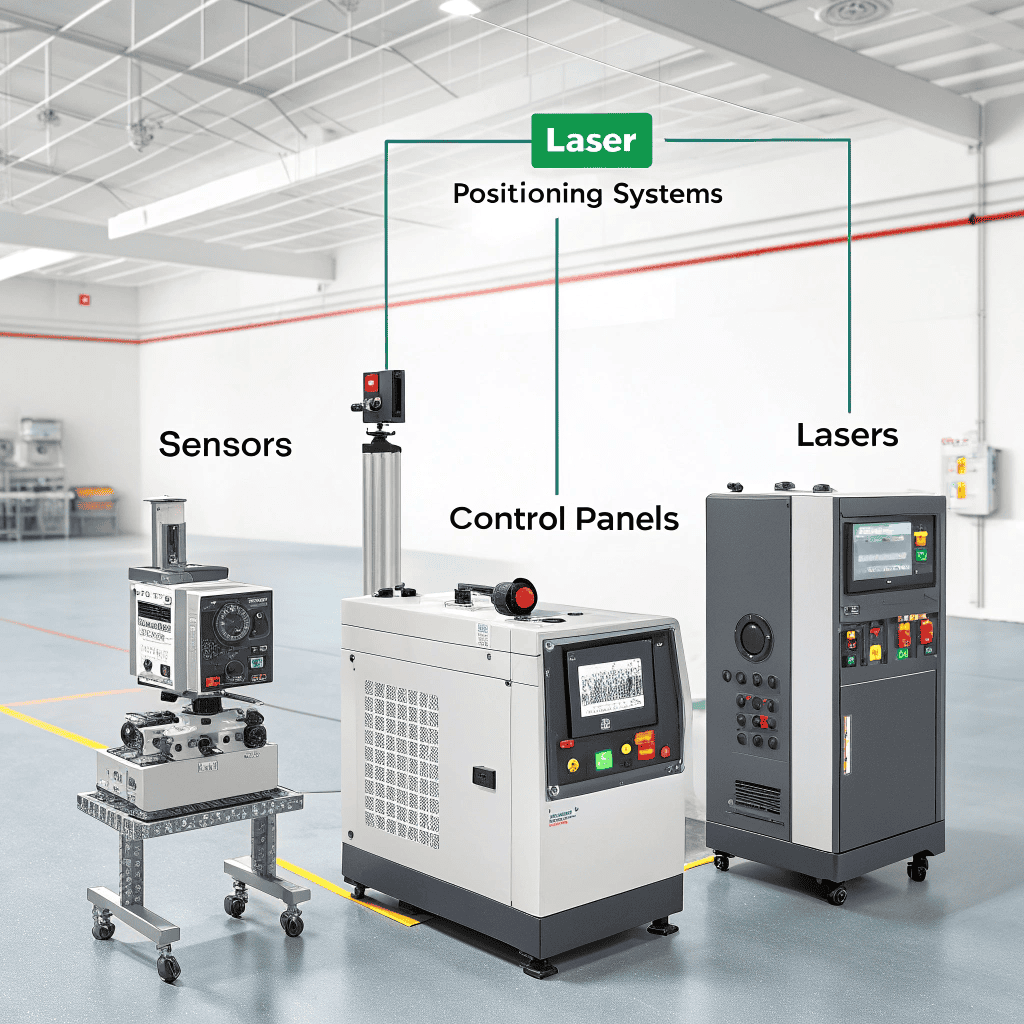

What is a Laser Positioning System?

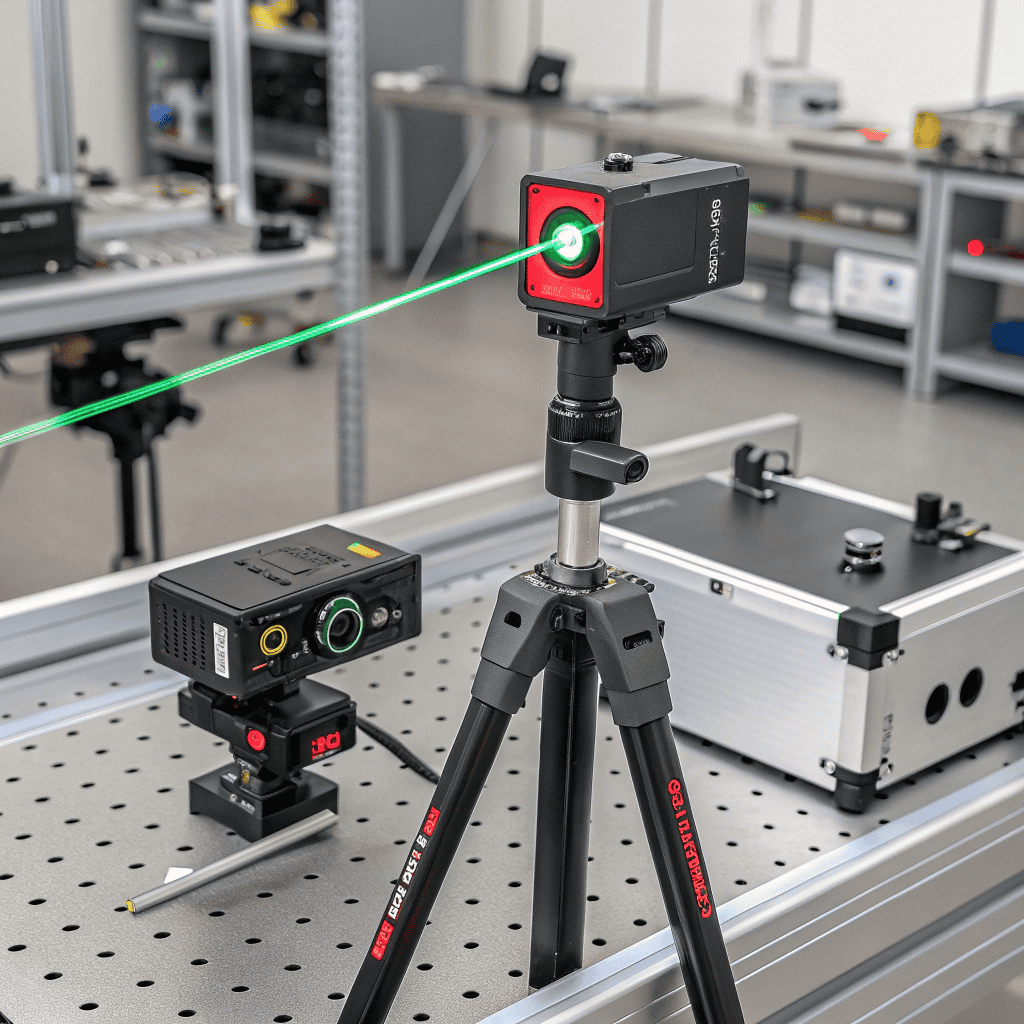

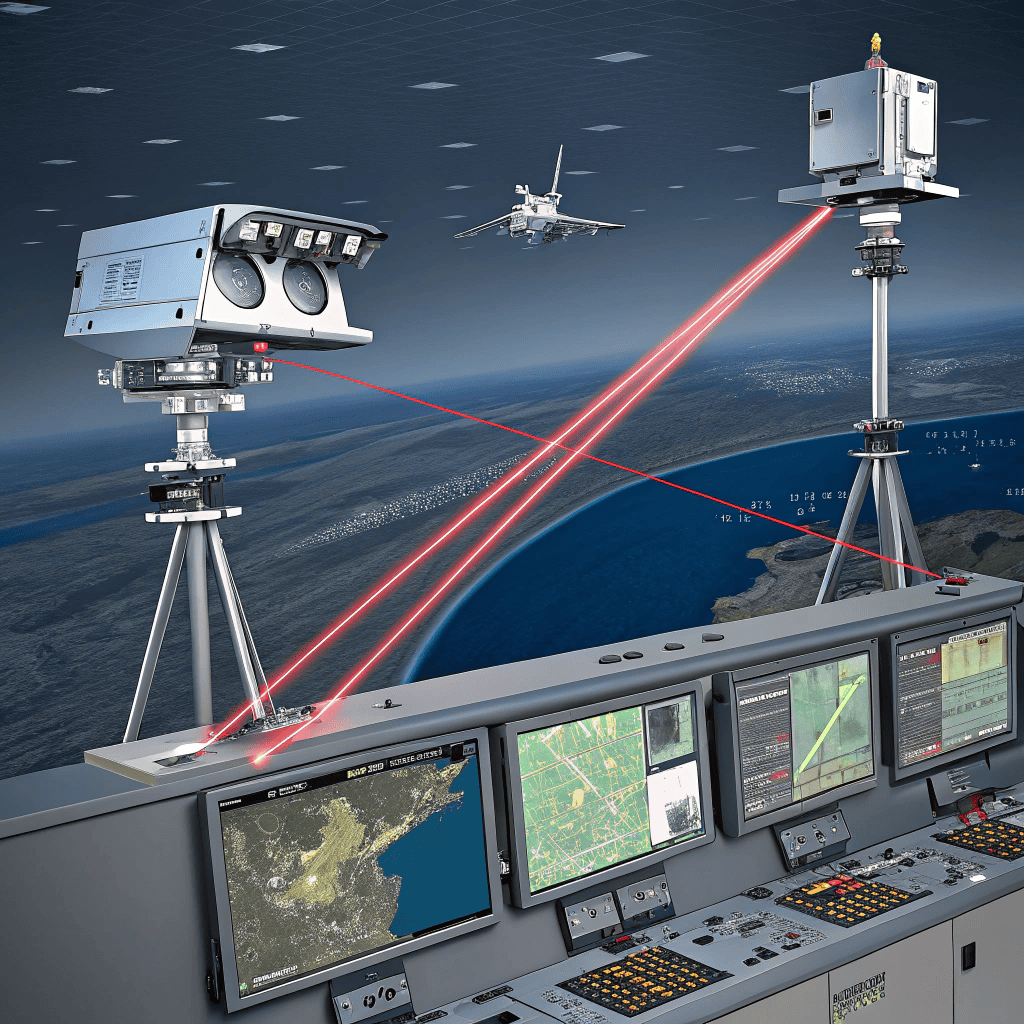

A laser positioning system is an advanced optical-mechanical setup that uses laser beams to precisely locate, guide, or measure positions during machining tasks such as cutting, drilling, engraving, or alignment.

These systems are designed to achieve sub-millimeter to micron-level tolerances, making them indispensable in modern manufacturing environments where precision is paramount.

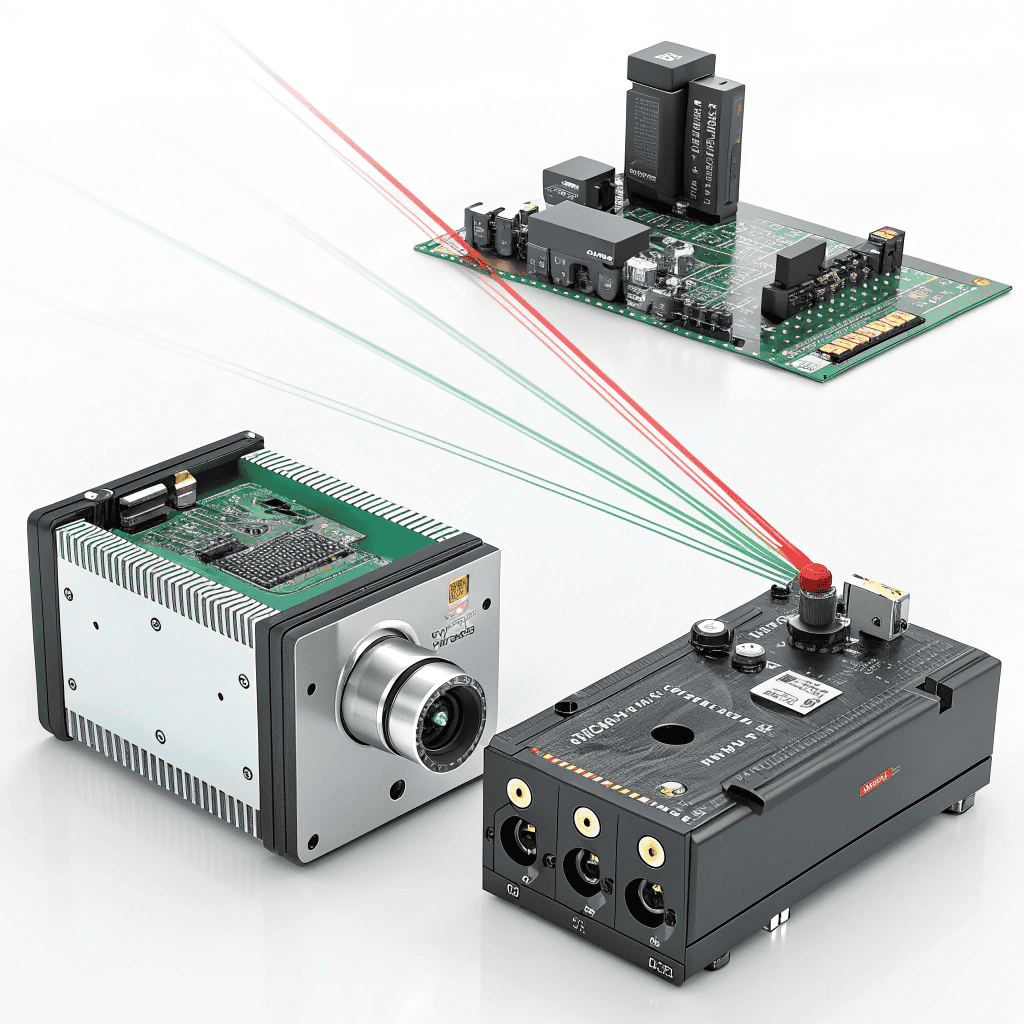

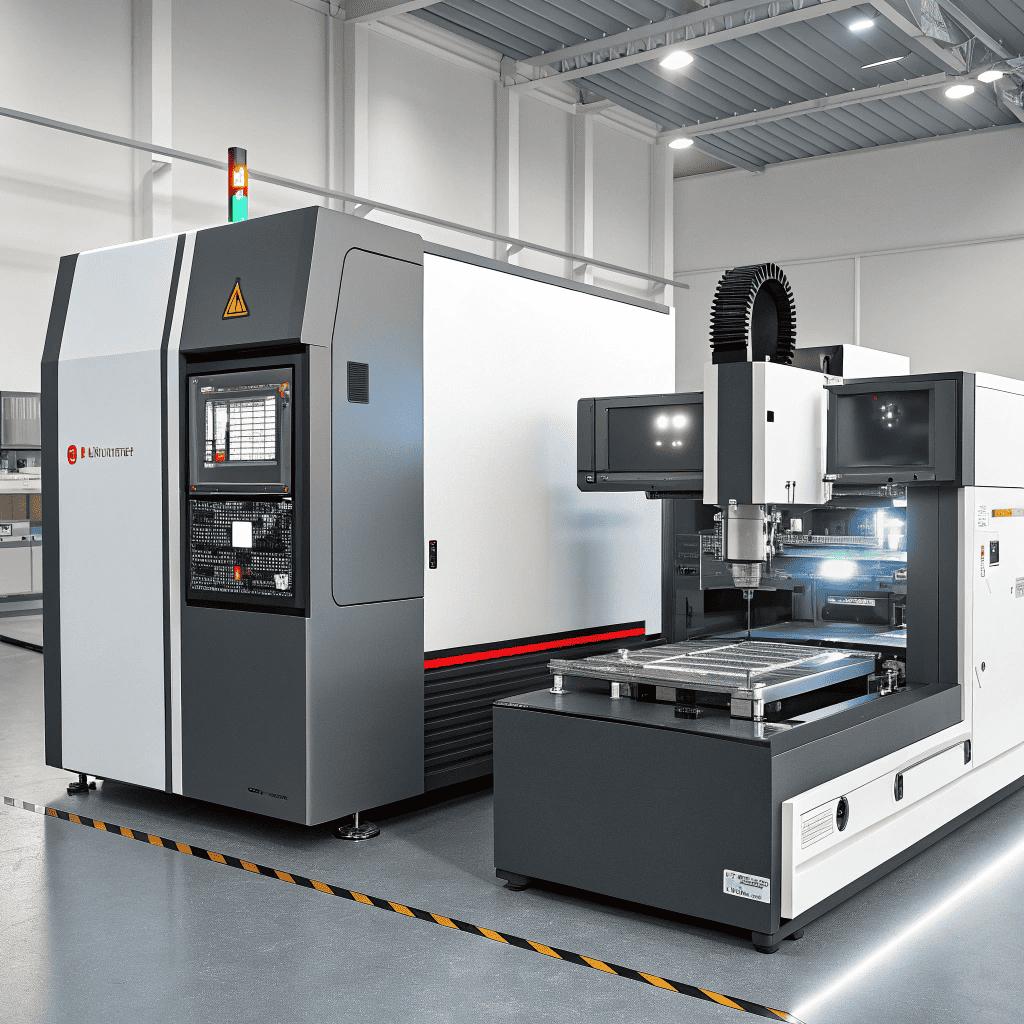

At its core, a laser positioning system integrates a laser source, beam delivery optics, and motion control mechanisms to direct the laser with pinpoint accuracy. These systems are often paired with computer numerical control (CNC) platforms, machine vision, and AI-driven software to ensure consistent performance across a wide range of materials and geometries.

By eliminating physical contact with the workpiece, laser positioning systems minimize wear, reduce mechanical stress, and enable intricate designs that would be impossible with traditional tools.

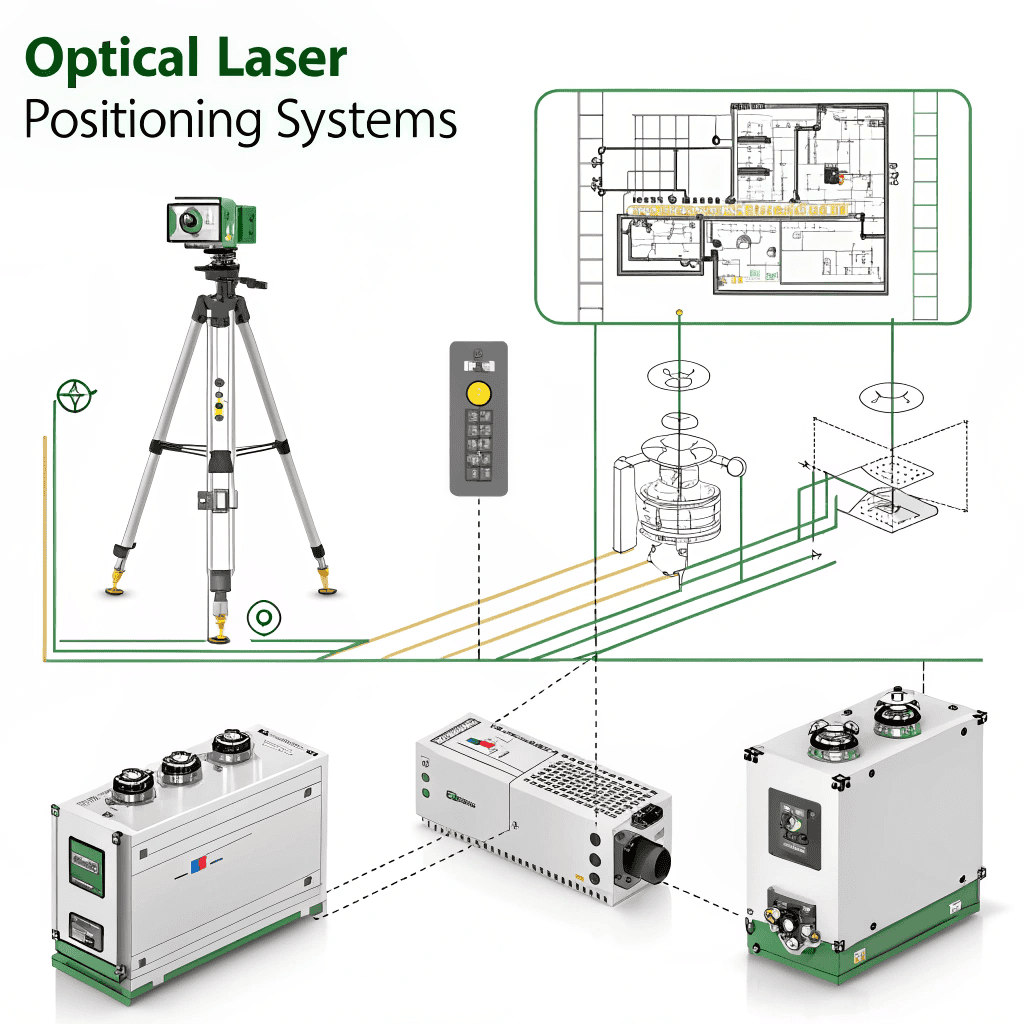

Technical Specifications of Optical Laser Positioning Systems

Optical laser positioning systems calculate distances to moving system parts contact-free, quickly and with absolute precision. In cycles lasting just milliseconds, the laser distance measuring system provides the position values required for dynamic control functions with millimeter accuracy using a selection of Industrial Ethernet and fieldbus interfaces.

With these sensors, distances of up to 300 m can be calculated with maximum accuracy through the use of the latest signal processors. Borderline situations are detected and also diagnostic data indicated with the integrated, extensive functionality catalog.

Repeatability of 1 mm, with tested absolute measurement accuracy from ±2 mm to ±5 mm. With the PROFINET and PROFIBUS variants, a parallel SSI interface is available to directly supply the frequency inverter with position data.

Key Benefits of Laser Positioning Systems

- Precision and Accuracy: Achieve tolerances as tight as ±1 micron, critical for industries like aerospace and medical device manufacturing.

- Non-Contact Processing: Eliminates tool wear and reduces the risk of material deformation.

- Versatility: Capable of processing metals, ceramics, polymers, composites, and more.

- High Throughput: Enables rapid production with minimal setup time, ideal for high-volume manufacturing.

- Minimal Waste: Focused laser beams reduce material waste compared to mechanical cutting methods.

Core Technologies Behind Laser Positioning Systems

Laser positioning systems rely on a synergy of advanced technologies to deliver unmatched precision, speed, and reliability. Below are the key components and their roles in enabling high-precision laser machining:

1. Galvanometer Scanners

A galvanometer scanner is a highly dynamic electro-optical component that uses a rotatable low-inertia mirror to position a laser beam with high precision and repeatability.

This technology is integral to galvanometer scanner laser systems, which are versatile, accurate, and easy to use, making them ideal for a wide range of applications across various industries.

Galvo scanners are particularly effective for high-speed applications like laser cutting, drilling, and micromachining, where they can achieve beam deflection rates of up to thousands of movements per second.

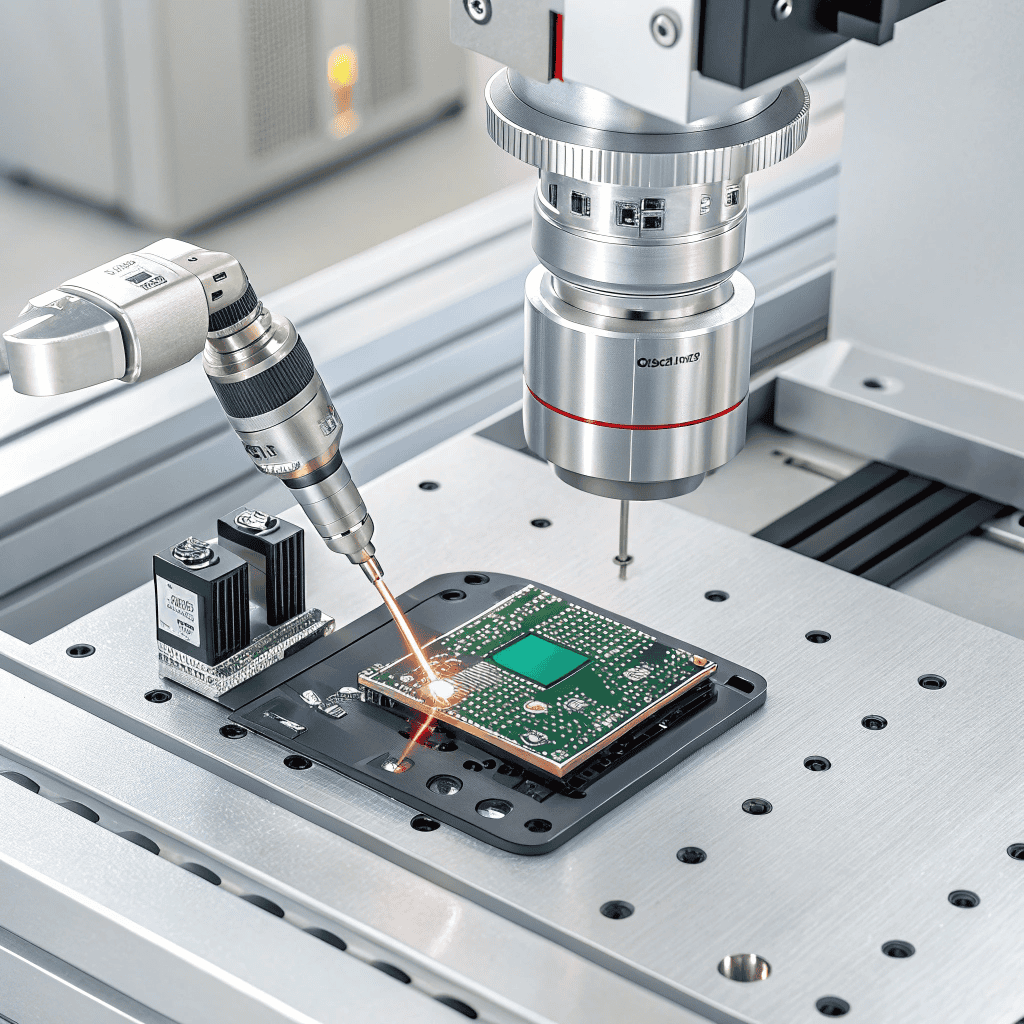

- Applications: Micro-drilling of printed circuit boards (PCBs), laser engraving, and precision cutting of thin films.

- Advantages: High-speed beam steering, low inertia, and compatibility with various laser wavelengths.

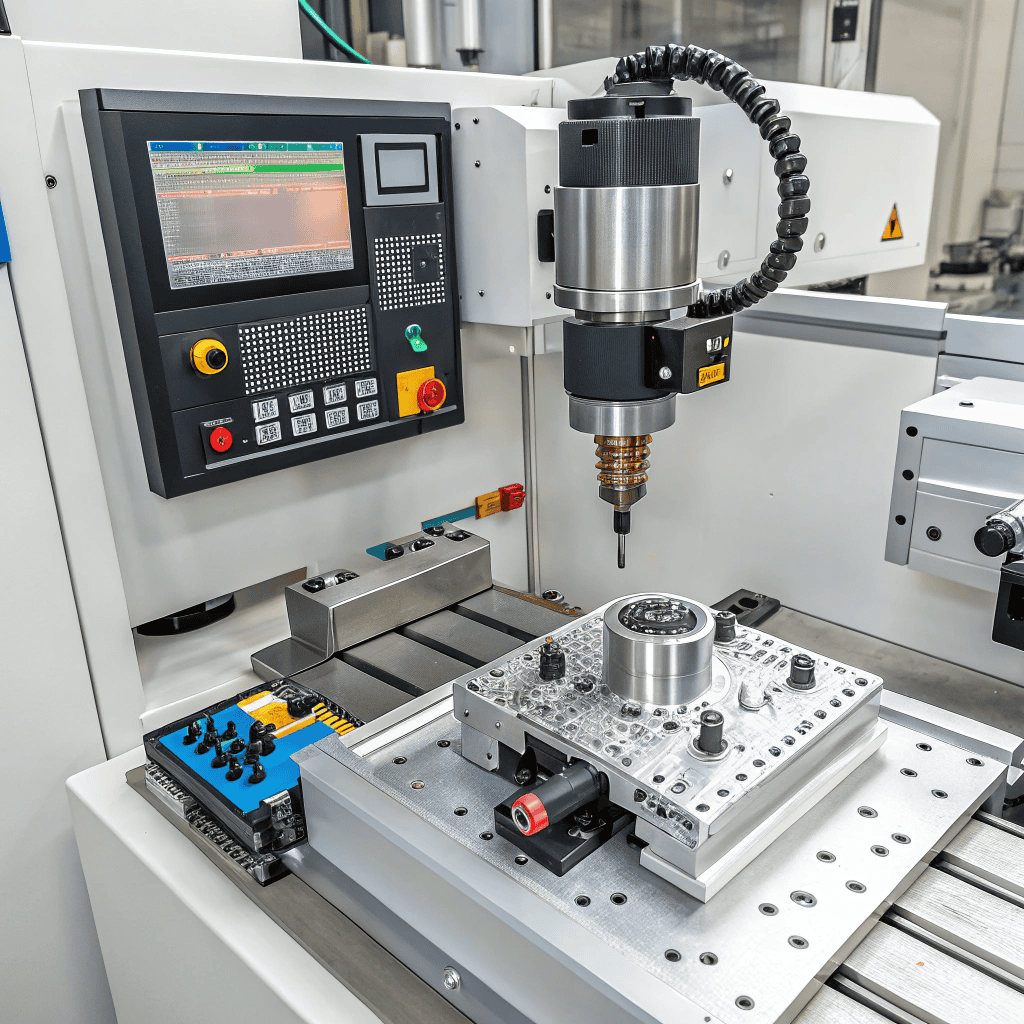

2. Computer Numerical Control (CNC)

CNC systems provide automated and repeatable motion control, translating digital designs (e.g., CAD files) into physical outcomes with micron-level accuracy. In laser positioning systems, CNC platforms control the movement of the laser head, workpiece, or both, ensuring precise alignment and consistent results.

Modern CNC systems are equipped with multi-axis control, allowing complex 3D geometries to be machined with ease.

- Applications: Cutting intricate patterns in aerospace components, drilling micro-holes in fuel injectors.

- Advantages: High repeatability, scalability for large production runs, and integration with CAD/CAM software

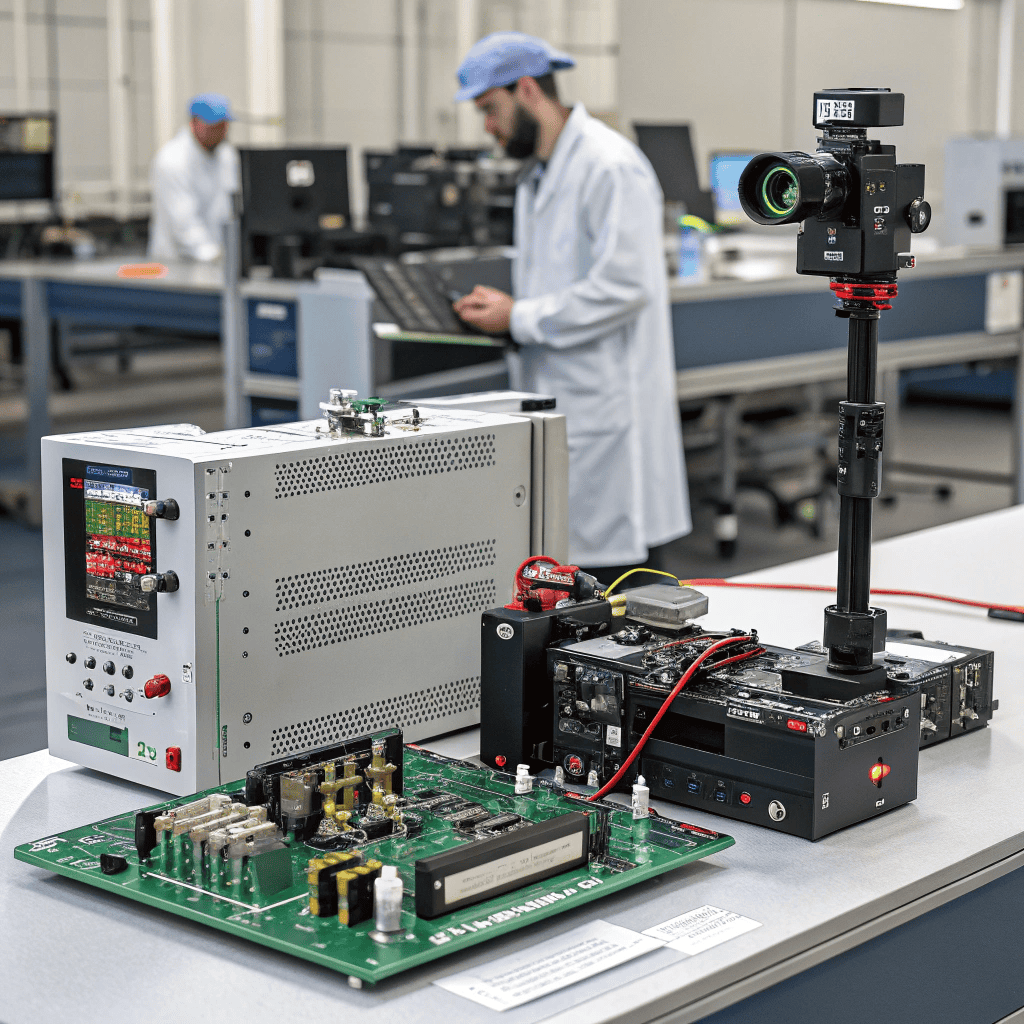

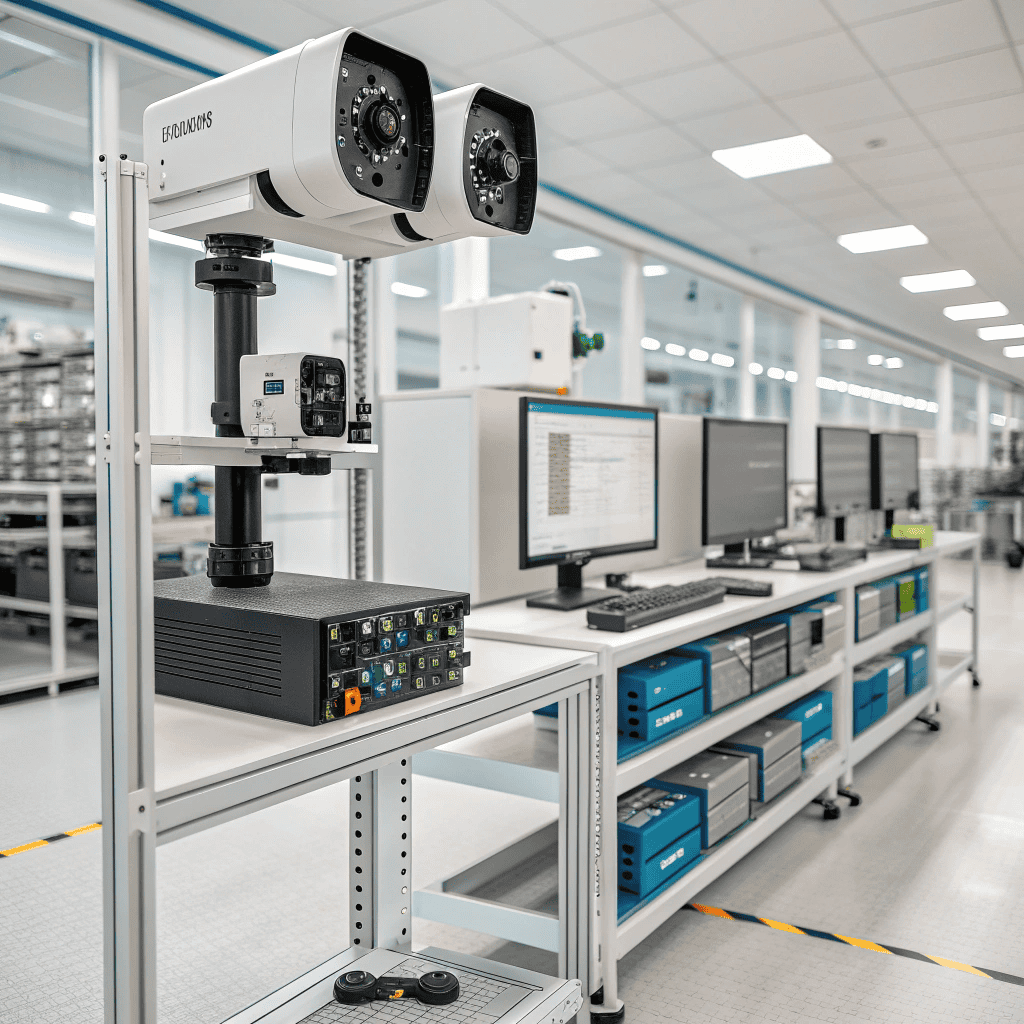

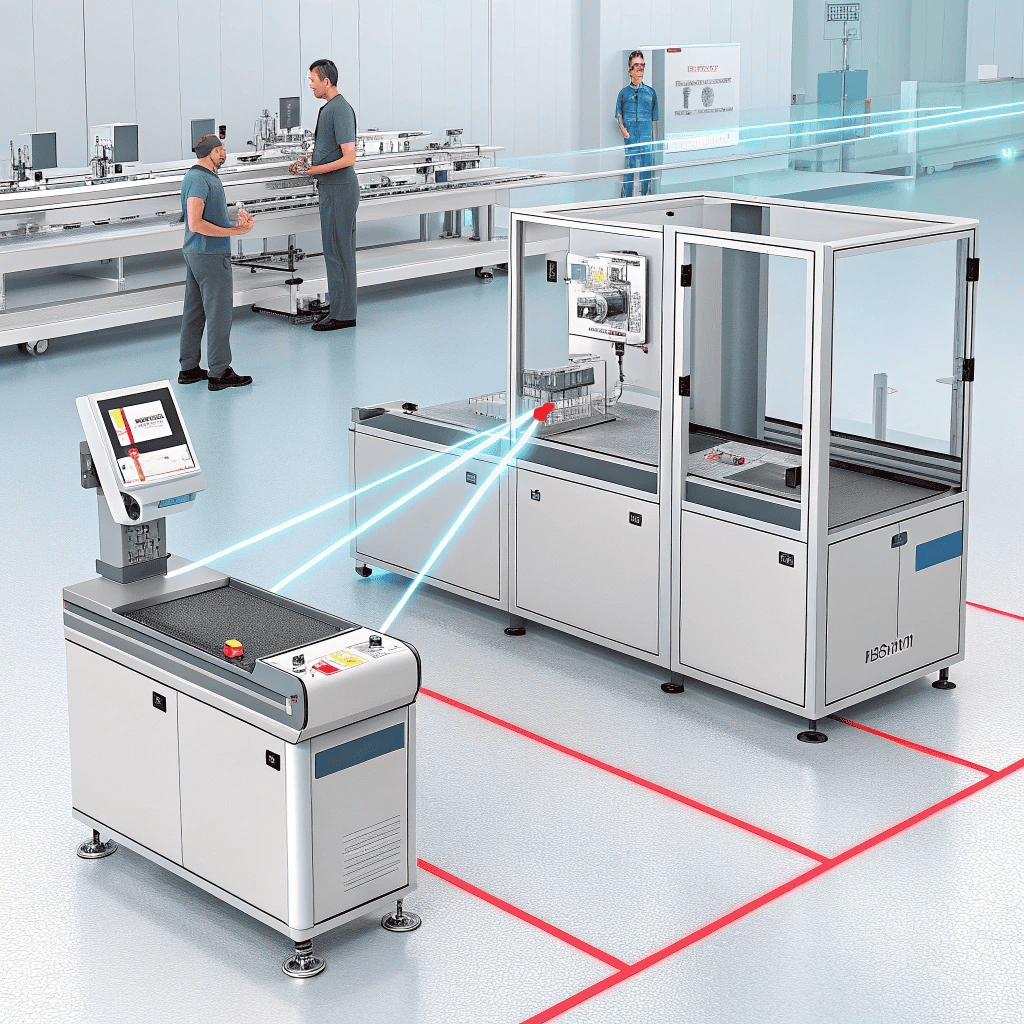

3. Machine Vision Systems

Machine vision systems enhance laser positioning accuracy by providing real-time monitoring and alignment correction. These systems use high-resolution cameras and image-processing algorithms to detect workpiece features, verify alignment, and ensure quality control.

By integrating machine vision, manufacturers can achieve closed-loop feedback, where the system automatically adjusts the laser’s position based on real-time data.

- Applications: Aligning laser cuts on pre-patterned substrates, inspecting micro-drilled holes for defects.

- Advantages: Reduces human error, improves quality assurance, and enables adaptive machining.

4. Adaptive Optics

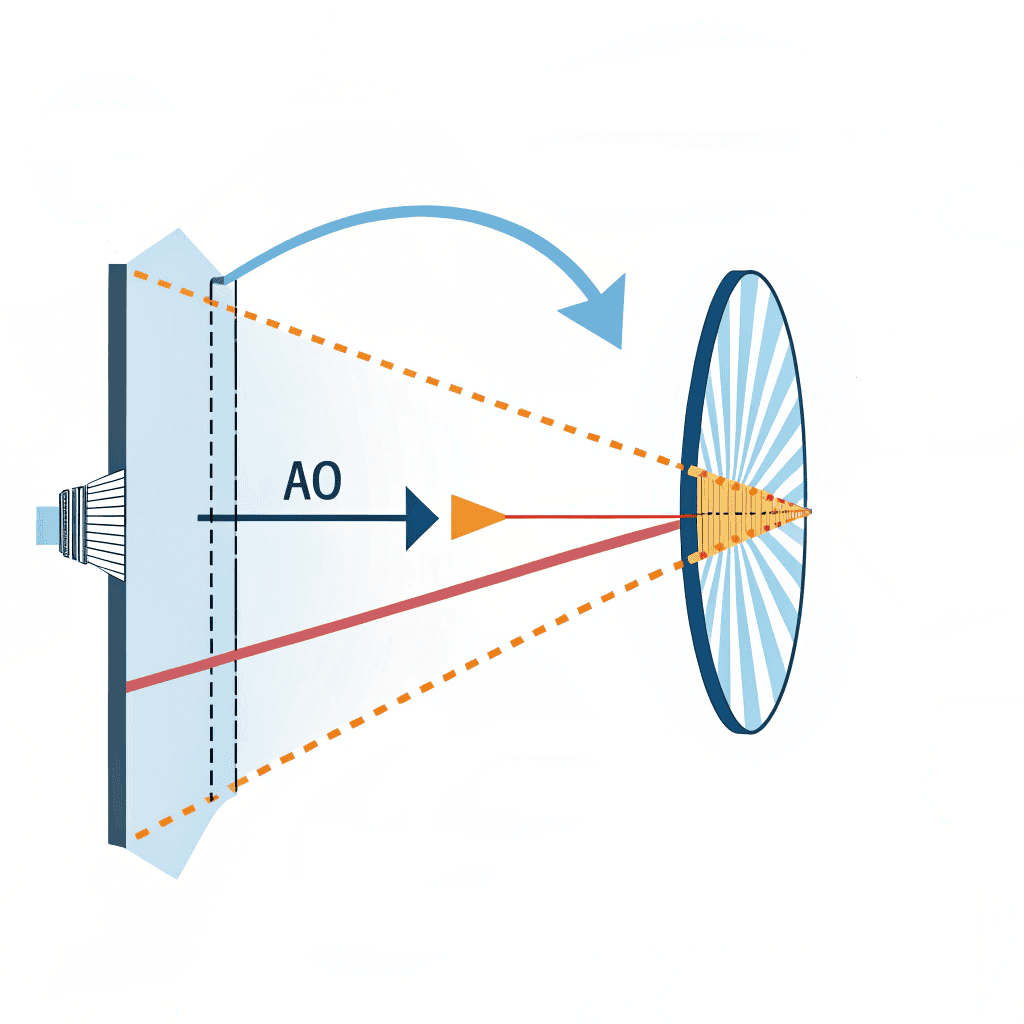

Adaptive optics (AO) is a technique of precisely deforming a mirror in order to compensate for light distortion. Adaptive optics dynamically adjust the laser beam’s shape, focus, and intensity based on material properties or part geometry.

By compensating for variations in surface curvature, thickness, or reflectivity, adaptive optics ensure consistent machining quality across complex workpieces.

These systems often incorporate deformable mirrors or liquid-crystal spatial light modulators to fine-tune the beam in real time.

- Applications: Cutting or drilling multi-layer materials, machining curved surfaces in optical components.

- Advantages: Enhances beam quality, improves depth control, and reduces thermal effects.

5. AI and Predictive Algorithms

AI and predictive algorithms are transforming laser positioning systems by optimizing tool paths, reducing cycle times, and predicting potential deviations before they occur.

Machine learning models analyze historical machining data to identify patterns, enabling proactive adjustments to parameters like laser power, speed, or focus. AI also facilitates predictive maintenance, minimizing downtime by forecasting equipment wear.

- Applications: Optimizing laser cutting paths for complex geometries, predicting material behavior during drilling.

- Advantages: Increases efficiency, reduces errors, and supports automation in smart factories.

These core technologies work together to deliver the laser cutting positioning accuracy and repeatability required for modern, high-precision applications. By combining high-speed galvo scanners, precise CNC control, real time vision feedback, adaptive optics, and AI-driven optimization, laser positioning systems achieve unparalleled performance.

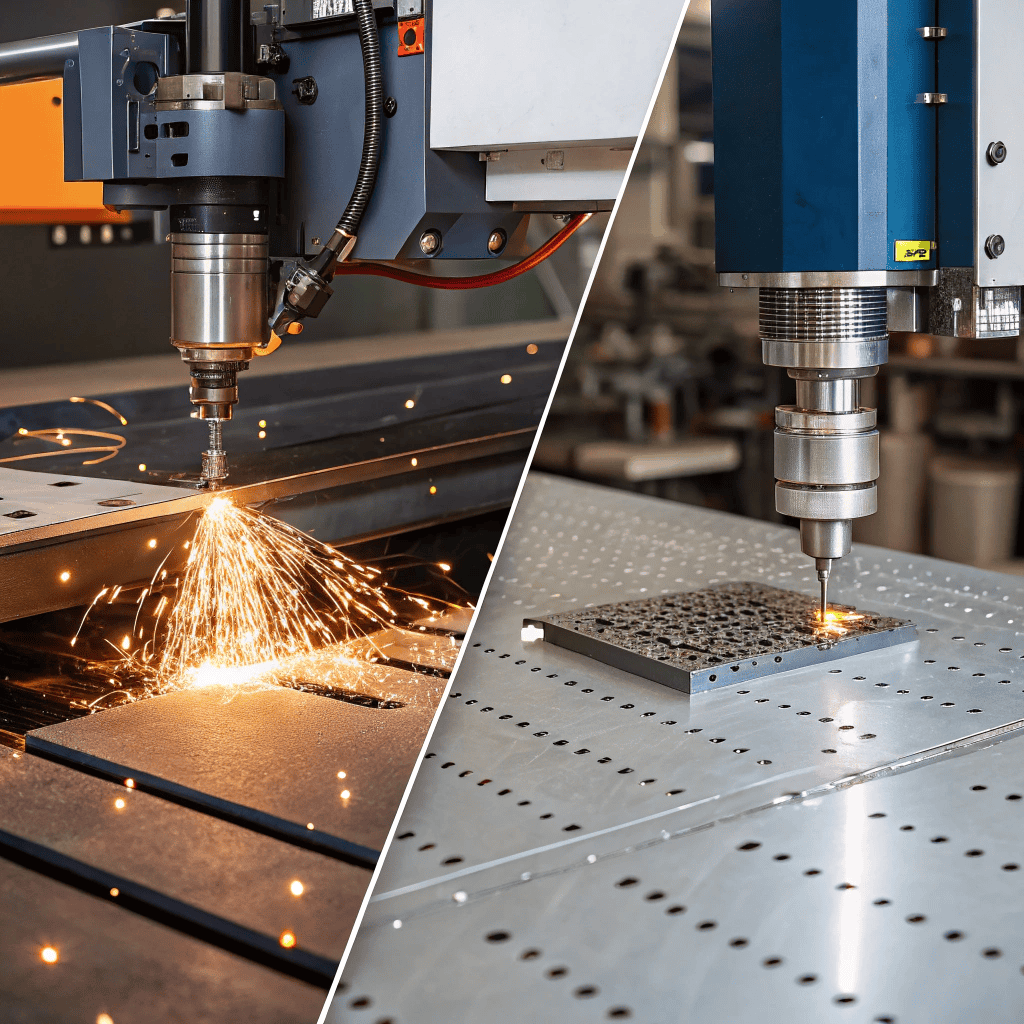

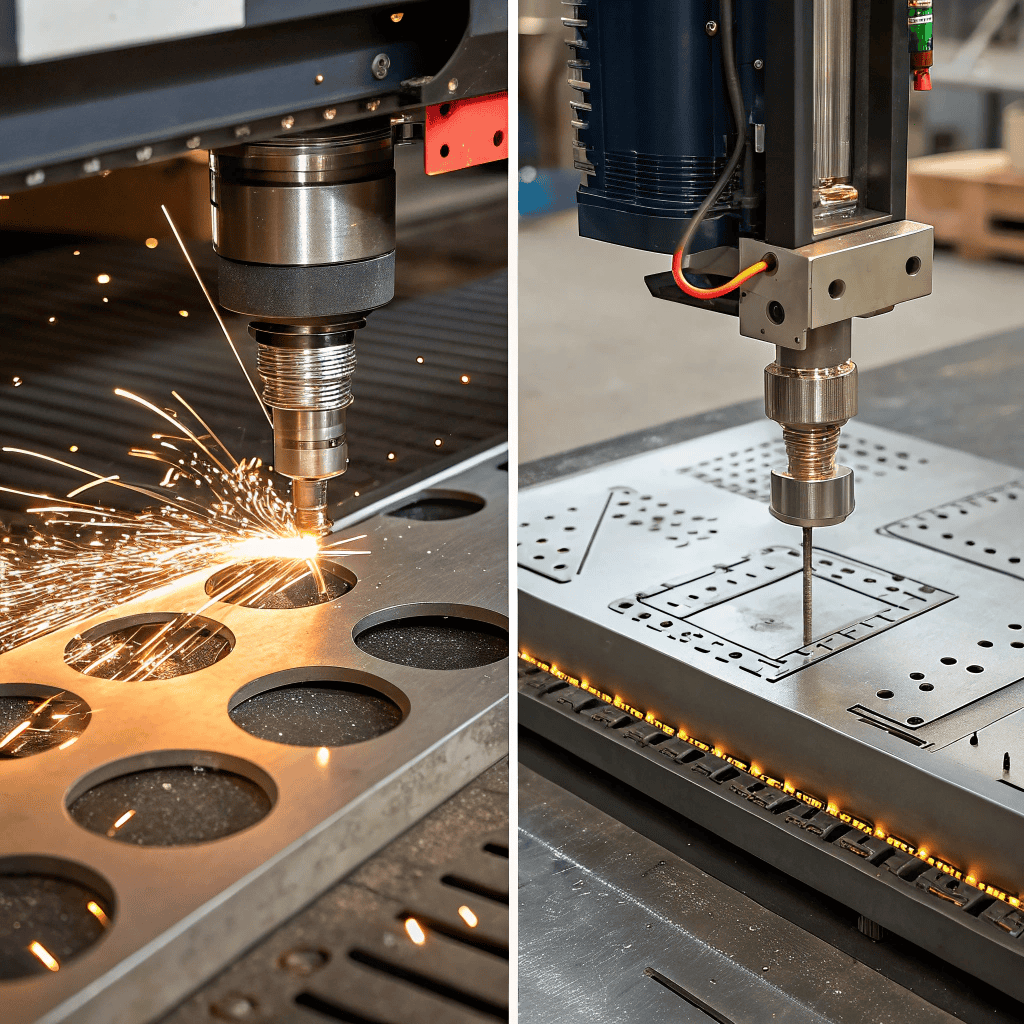

Laser Cutting vs. Laser Drilling: Key Differences

While laser cutting and laser drilling share similar technologies, their processes, applications, and challenges differ significantly. Understanding these differences is crucial for selecting the right approach for specific manufacturing needs.

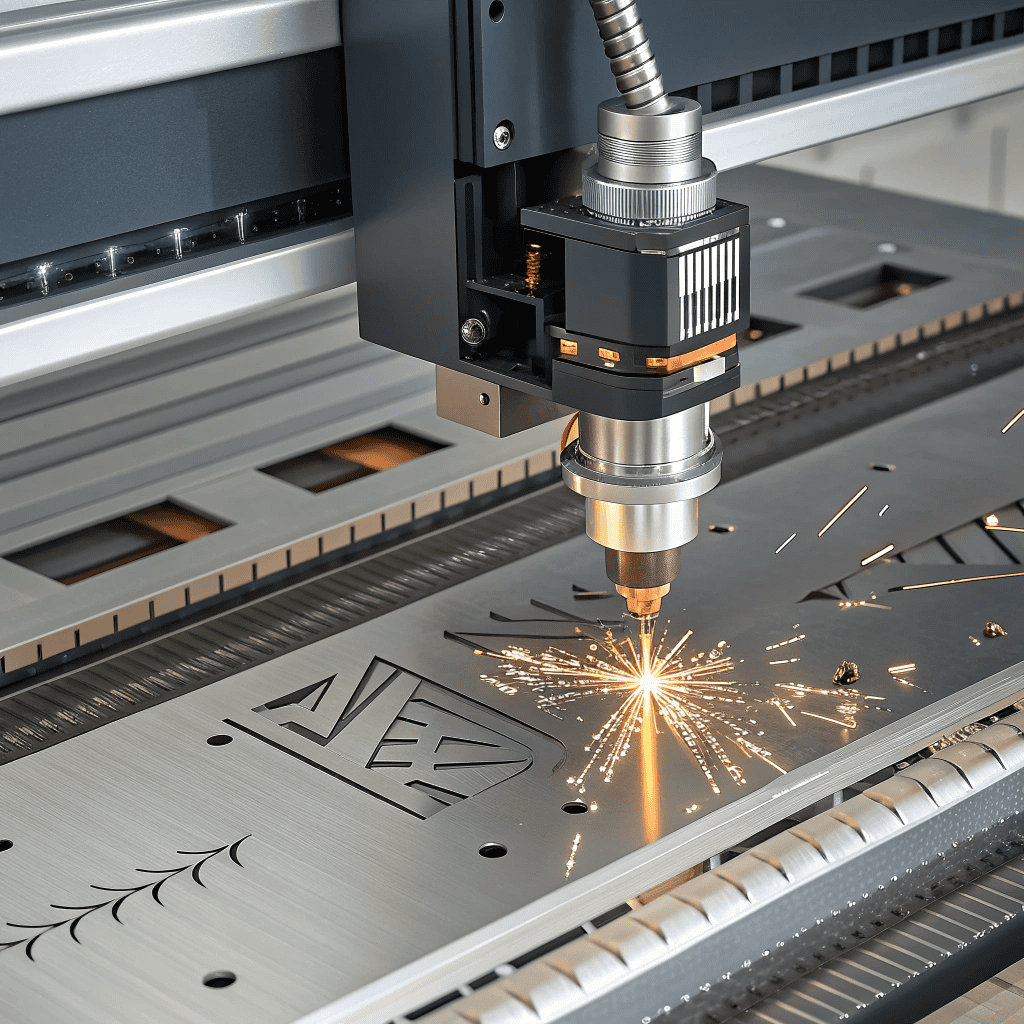

Laser cutting is a fascinating process that utilizes a focused high-power-density laser beam to cut materials.

Laser Cutting

Definition: Laser cutting uses a focused laser beam to melt, vaporize, or burn through a material, creating clean, precise cuts along a predetermined path.

- Process: The laser beam is guided by a CNC system or galvo scanner to follow a 2D or 3D cutting path. The beam’s energy is absorbed by the material, causing localized heating and material removal.

- Applications:

- Cutting intricate patterns in sheet metal for automotive parts.

- Shaping composite materials for aerospace components.

- Fabricating micro-structures in semiconductor wafers.

- Key Parameters:

- Laser Power: Determines cutting speed and depth (e.g., 1-20 kW for industrial fiber lasers).

- Beam Focus: Affects kerf width (typically 0.1-0.5 mm).

- Cutting Speed: Balances quality and throughput (e.g., 10-100 mm/s for metals).

- Advantages:

- High precision with minimal kerf width.

- Suitable for a wide range of materials, including metals, plastics, and composites.

- Minimal mechanical stress on the workpiece.

- Challenges:

- Managing heat-affected zones (HAZ) to prevent material distortion.

- Optimizing assist gases (e.g., nitrogen, oxygen) for clean cuts.

Laser Drilling

Definition: Laser drilling uses a focused laser beam to create holes of varying sizes and depths in a material, often with micron-level precision.

- Process: The laser delivers short, high-energy pulses to remove material layer by layer, forming a hole. Techniques like percussion drilling (repeated pulses at a single point) or trepanning (circular beam motion) are used depending on hole size and depth.

- Applications:

- Drilling micro-holes in medical stents or catheters.

- Creating cooling holes in aerospace turbine blades.

- Fabricating vias in printed circuit boards (PCBs).

- Key Parameters:

- Pulse Duration: Short pulses (nanoseconds to femtoseconds) minimize thermal damage.

- Hole Diameter: Ranges from microns to millimeters.

- Aspect Ratio: Depth-to-diameter ratio, critical for deep-hole drilling.

- Advantages:

- Capable of drilling high-aspect-ratio holes with minimal taper.

- Non-contact process reduces tool wear and enables complex geometries.

- High repeatability for mass production.

- Challenges:

- Controlling recast layers (molten material redepositing around the hole).

- Managing thermal effects in heat-sensitive materials.

Key Differences

| Aspect | Laser Cutting | Laser Drilling |

| Objective | Create continuous cuts or shapes | Form discrete holes of specific sizes |

| Beam Motion | Continuous path along a 2D/3D trajectory | Stationary or circular (trepanning) |

| Material Removal | Material is melted/vaporized along a path | Material is ablated layer by layer |

| Applications | Sheet metal cutting, patterning | Micro-hole drilling, via formation |

| Challenges | Managing kerf width and HAZ | Controlling hole taper and recast layers |

By understanding these distinctions, manufacturers can select the appropriate laser machining process based on their specific requirements, whether it’s cutting complex shapes or drilling precise holes.

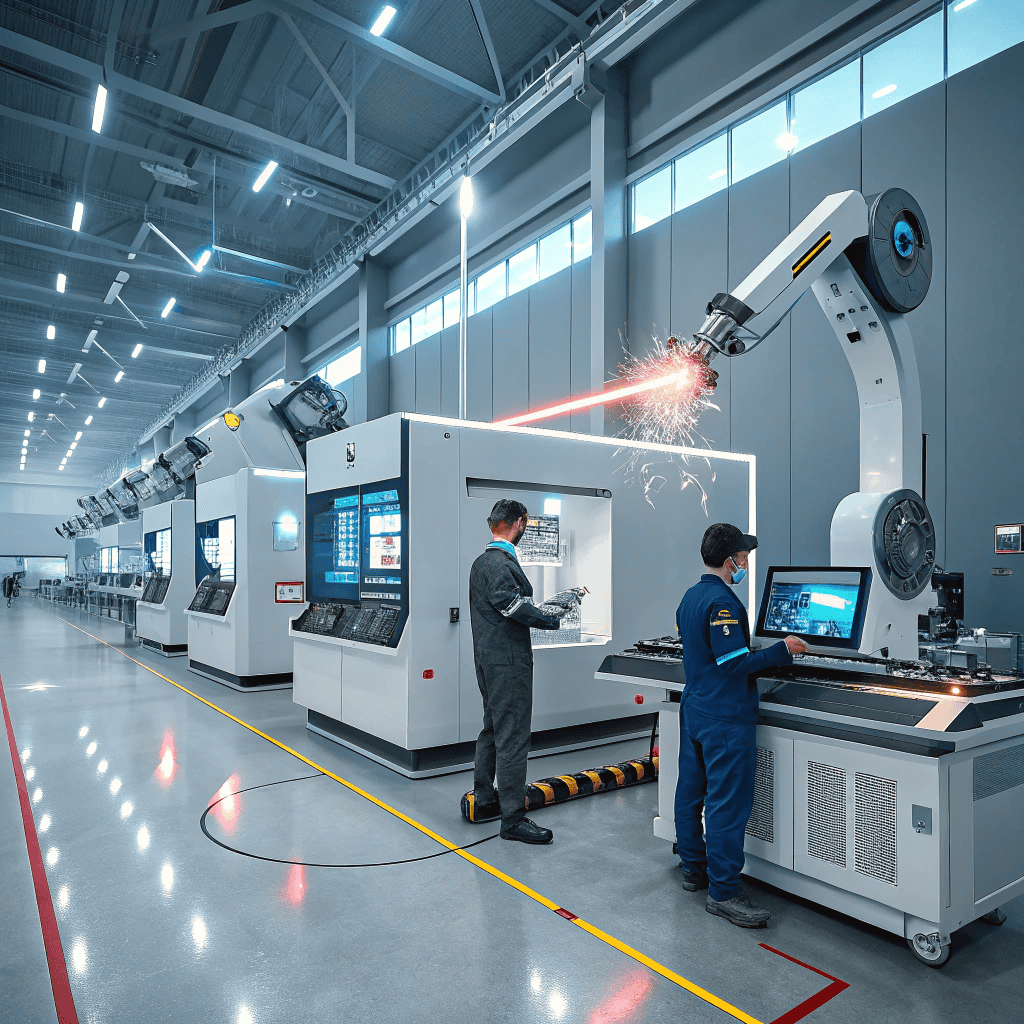

Industrial Applications of Laser Positioning Systems

Laser positioning systems are transforming industries by enabling high-precision machining in diverse applications. Below are some key sectors and their use cases:

1. Aerospace

- Application: Cutting and drilling turbine blades, engine components, and composite airframe parts.

- Benefits: Micron-level accuracy ensures tight tolerances, while non-contact processing minimizes material stress in high-performance alloys.

- Example: Drilling thousands of cooling holes in turbine blades with diameters as small as 0.3 mm.

2. Medical Device Manufacturing

- Application: Fabricating stents, catheters, tooling plates, and surgical instruments with micro-scale features.

- Benefits: Ultra-precise laser drilling and cutting enable biocompatible materials like titanium and nitinol to be machined without compromising structural integrity.

- Example: Drilling 50-micron holes in stents for drug delivery.

3. Electronics and Semiconductors

- Application: Cutting and drilling PCBs, creating micro-vias, and patterning thin films.

- Benefits: High-speed galvo scanners and machine vision ensure accurate placement of features on densely packed substrates.

- Example: Drilling 10-micron vias in multi-layer PCBs for high-density interconnects.

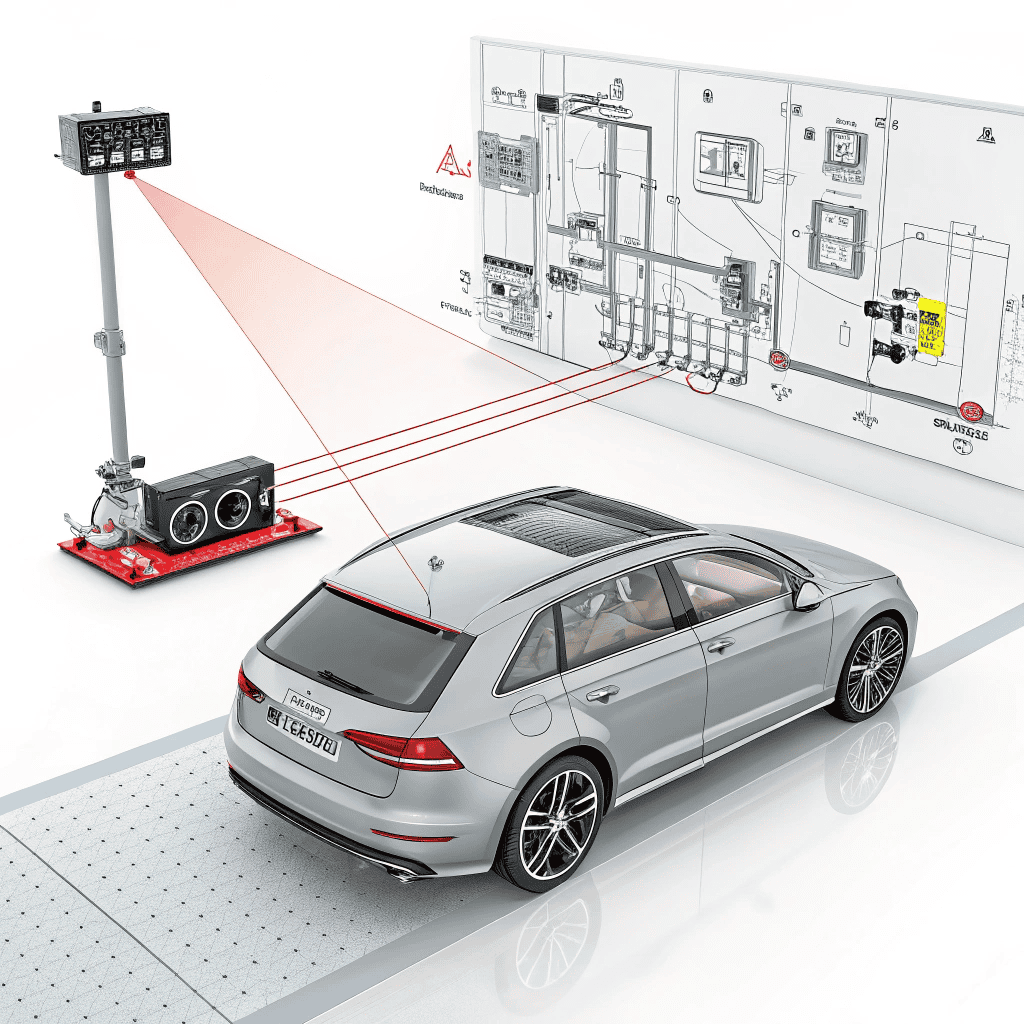

4. Automotive

- Application: Cutting body panels, car parts, drilling fuel injector nozzles, and shaping lightweight composites.

- Benefits: Laser systems reduce material waste and enable rapid prototyping of complex parts.

- Example: Cutting carbon-fiber-reinforced polymer (CFRP) panels for electric vehicle chassis.

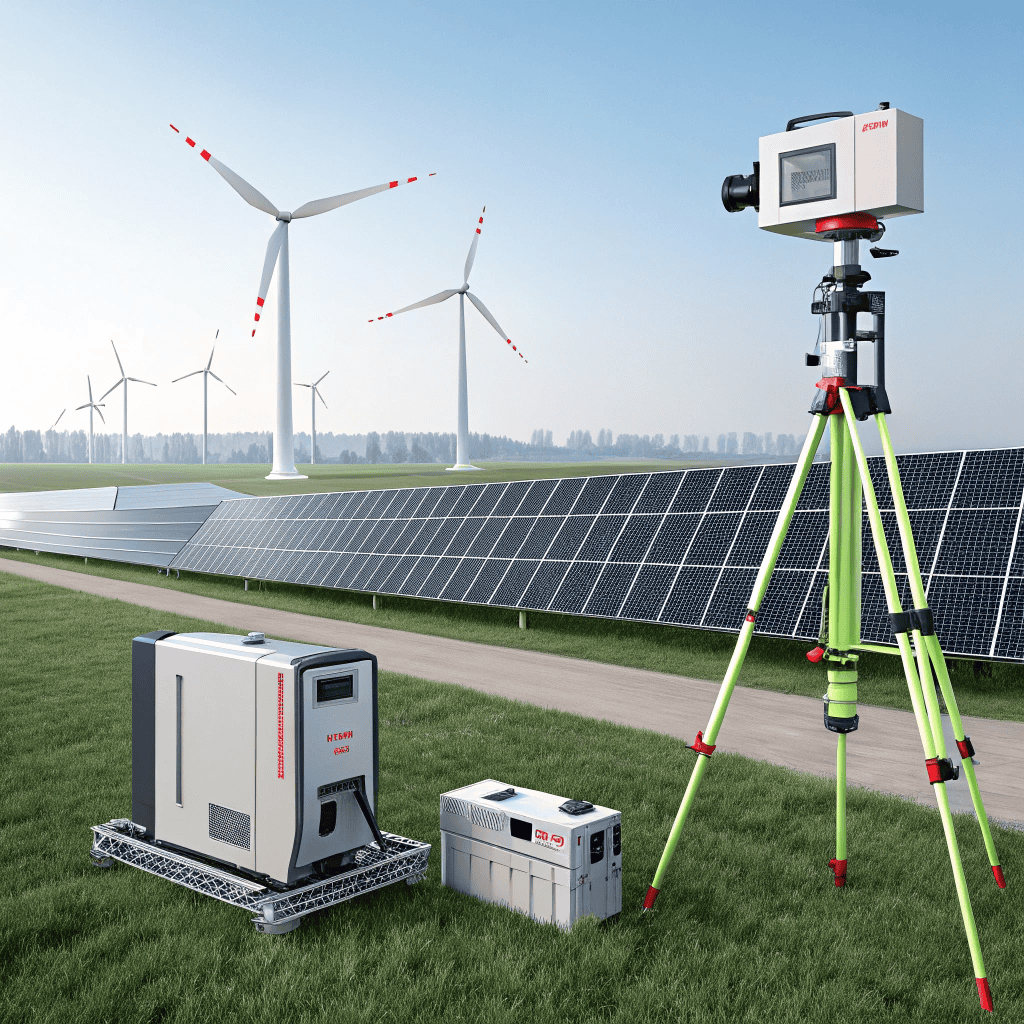

5. Energy and Renewable Technologies

- Application: Fabricating solar cells, battery components, and fuel cell membranes.

- Benefits: Precise laser cutting and drilling improve efficiency and performance in energy-critical applications.

- Example: Patterning thin-film solar cells to enhance electrical conductivity.

These applications demonstrate the versatility and impact of laser positioning systems across industries, enabling manufacturers to meet stringent quality and performance standards.

Choosing the Right Laser Positioning System

Selecting the appropriate laser positioning system requires careful consideration of several factors, including material type, machining requirements, and production goals. Below are key considerations to guide your decision:

1. Laser Type

- Fiber Lasers: Ideal for cutting and drilling metals due to high power and efficiency (e.g., 1-20 kW).

- CO2 Lasers: Suitable for non-metals like plastics, wood, and ceramics.

- Ultrashort-Pulse Lasers: Best for micro-drilling and heat-sensitive materials due to minimal thermal impact (e.g., picosecond or femtosecond pulses).

2. Power and Pulse Characteristics

- Choose laser power based on material thickness and desired throughput (e.g., 500 W for thin metals, 10 kW for thick steel).

- For drilling, prioritize pulse duration and energy for precise material removal.

3. Positioning Accuracy

- Ensure the system offers sub-micron repeatability for high-precision tasks.

- Galvo scanners or high-resolution CNC stages are critical for achieving tight tolerances.

4. Integration with Automation

- Look for systems compatible with Industry 4.0 standards, including AI-driven optimization and machine vision for real-time feedback.

- Ensure compatibility with existing CAD/CAM software for seamless workflow integration.

5. Material Compatibility

- Verify that the system can handle your target materials (e.g., reflective metals require specific wavelengths).

- Adaptive optics can enhance performance across diverse material types.

6. Scalability and Throughput

- For high-volume production, prioritize systems with fast galvo scanners and automated workpiece handling.

- Consider cycle times and maintenance requirements to maximize uptime.

7. Budget and Support

- Balance upfront costs with long-term value, including energy efficiency and maintenance needs.

- Choose suppliers with robust technical support and training programs.

By aligning these factors with your specific needs, you can select a laser positioning system that delivers optimal performance and return on investment.

Future Trends in High-Precision Laser Machining

The field of laser machining is evolving rapidly, driven by advancements in technology and growing industrial demands. However, the industry continues to innovate, and several emerging laser technologies offer even greater potential benefits.

Below are key trends shaping the future of laser positioning systems:

1. AI-Driven Optimization

AI and machine learning are increasingly integrated into laser positioning systems to optimize machining parameters, predict material behavior, and reduce cycle times. Predictive algorithms can adjust laser settings in real time, improving efficiency and quality.

Femtosecond and picosecond lasers are gaining traction for their ability to minimize thermal damage and achieve sub-micron precision. These lasers are ideal for micro-drilling and cutting heat-sensitive materials like semiconductors and biomaterials.

2. Hybrid Manufacturing

Combining laser machining with additive manufacturing (e.g., 3D printing) enables hybrid systems that can build and finish parts in a single setup. This trend is particularly impactful in aerospace and medical industries.

3. Green Manufacturing

Energy-efficient laser systems and processes that minimize material waste are becoming critical as industries prioritize sustainability. Fiber lasers, with their high efficiency, are leading this shift.

4. Augmented Reality (AR) Integration

AR systems are being used to visualize laser machining processes, aiding operators in setup, alignment, and quality control. This enhances productivity and reduces errors in complex operations.

5. Miniaturization and Micro-Machining

As demand for smaller, more precise components grows in electronics and medical sectors, laser positioning systems are evolving to support sub-micron accuracy and high-aspect-ratio features.

These trends highlight the dynamic nature of laser machining, positioning it as a cornerstone of next-generation manufacturing.

Final Words

Laser positioning systems are revolutionizing high-precision manufacturing, offering unmatched accuracy, speed, and versatility. By leveraging advanced technologies like galvanometer scanners, CNC control, machine vision, adaptive optics, and AI, these systems enable industries to meet the demands of modern production environments.

Whether cutting intricate aerospace components or drilling micro-holes in medical devices, laser machining delivers exceptional results with minimal waste and maximum efficiency.

Understanding the differences between laser cutting and drilling, evaluating industrial applications, and selecting the right system are critical steps for manufacturers aiming to stay competitive.

As AI, ultrafast lasers, and hybrid manufacturing continue to shape the future, laser positioning systems will remain at the forefront of innovation, driving precision and performance across industries.

Hanke Construction Machinery Manufacturing Co., Ltd is here to help you make it happen. We deliver high quality custom CNC machining services to meet your exact needs, every time.