CNC machines command tools that slice through metals, wood, or plastics with codes. These machines respond to commands like G-code. One of the basic commands would be G00, which means moving fast without cutting. G01, meaning cut in a straight line, and M03, meaning turn on the cutting tool (called the spindle).

Each command of CNC machines has its job. The commands instruct how to design and make anything with CNC machines. To learn, the codes must be written and applied. Start slowly and observe how the machine responds to the code.

Cut anything using this only after testing this code first. Write your steps out clearly and attempt to give them labels. Cleaning your tools and changing over the machine regularly is required. It means everything operates more smoothly. With trial and error on your side, you can master CNC g codes.

Understanding CNC Code

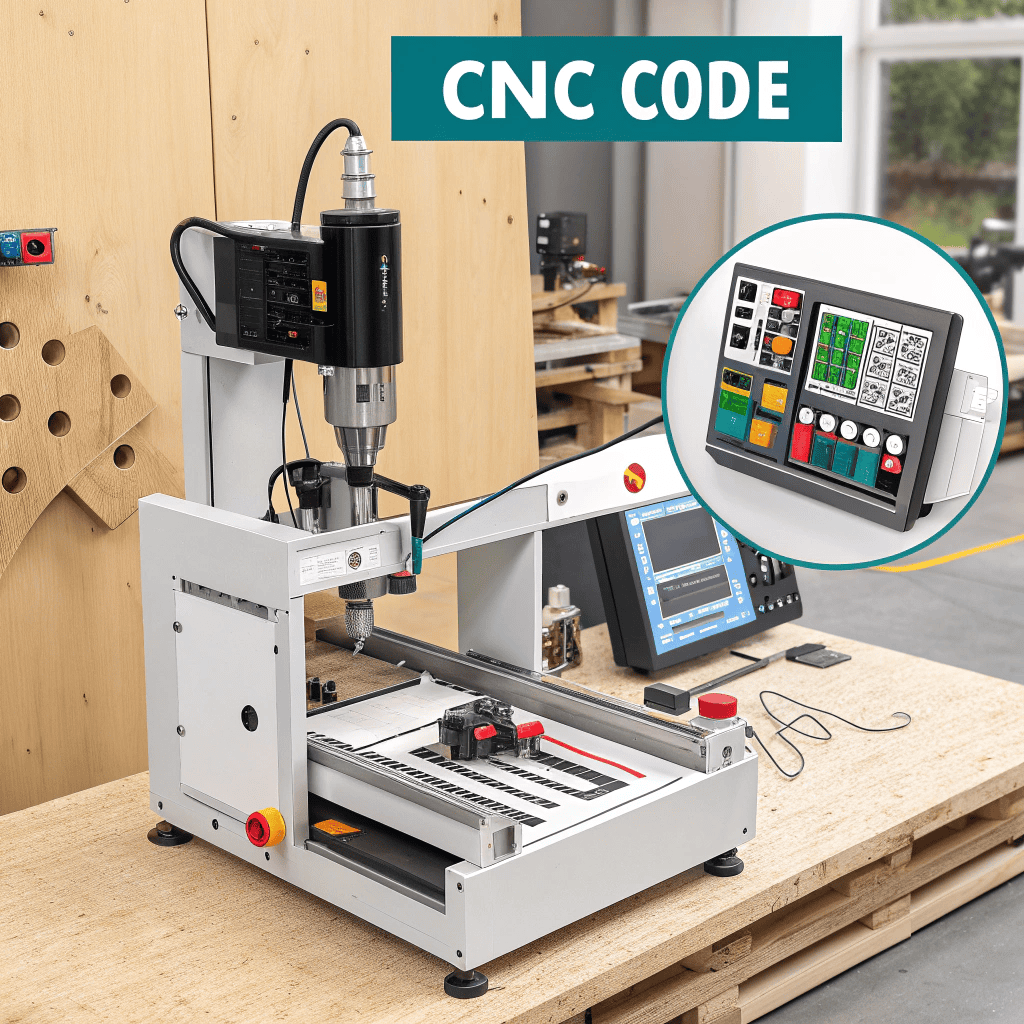

CNC code for beginners is a code-based communication protocol for CNC machines. It tells the machine where to move, how to cut, and what speed to travel. G-code is super important because it dictates everything the machine will do. Like cutting shapes, drilling holes, etc. The most prevalent form of CNC code is known as G-code.

G code for CNC describe how the machine moves like it should move in straight lines or circles. The other part of CNC code, called M-code, controls other elements. Such as enabling or disabling the machine’s tool. It helps making machines better and faster with no help every second. This special code allows CNC machines to carry out their tasks correctly.

Essential G Code Commands for CNC Machines

Instructions for movement are sent to CNC machines, and they are programmed like that. These instructions are known as G-code. CNC G code is a language that instructs the machine how to move, cut, or shape a material.

Wield yourself an endless number of G-code commands. However, not every machine implements all of these commands. The codes only apply to some machines. A few with higher codes are more used and operate on various machines.

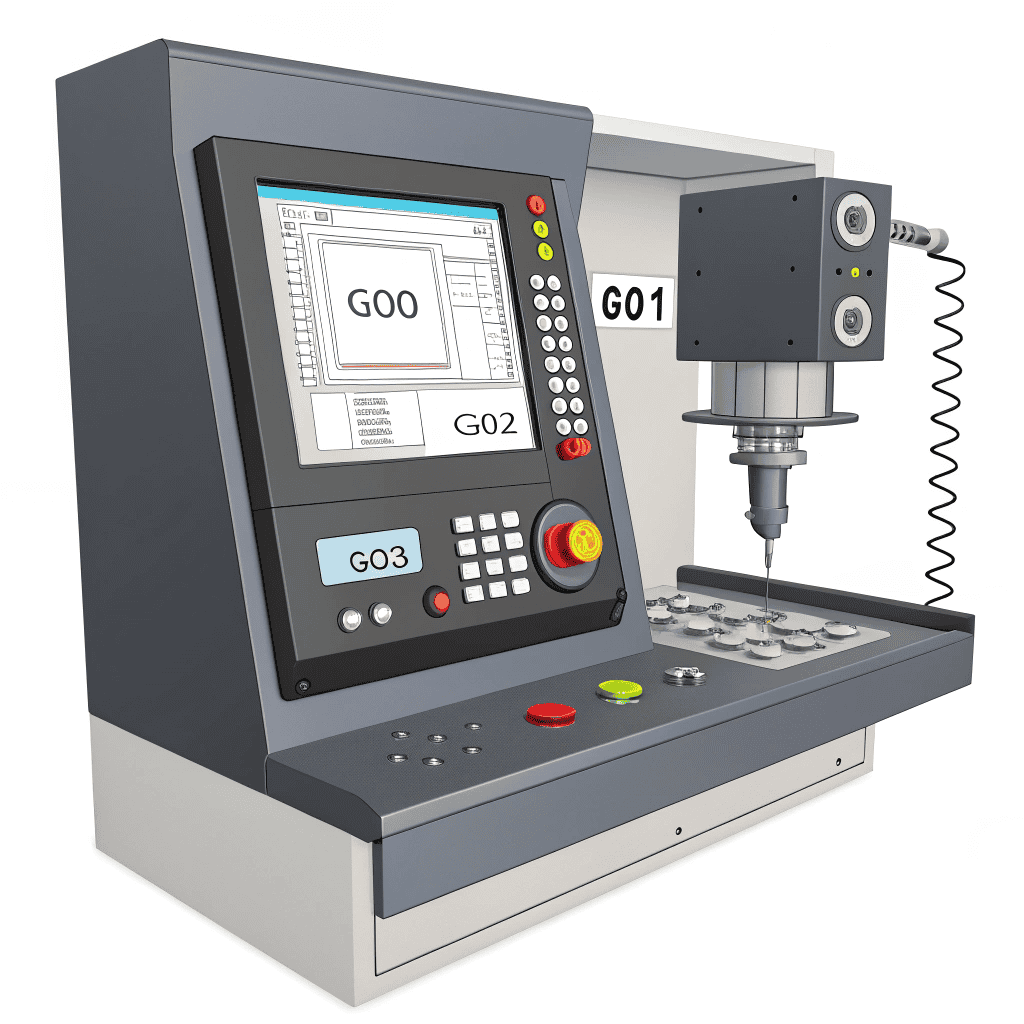

For example, the G00 command is a common CNC G code command. It tells the machine to move fast to a new location without cutting. G01 instructs the machine to make linear movements with cutting. G02, G03, use it when you want to cut with the machine in a curve or circle.

There are additional useful codes, such as G04 to tell the machine to wait and G28 to tell the machine to go back home. These codes allow people to communicate with CNC machines. This helps to create the correct shapes.

G00 – Rapid Positioning

Rapid positioning in CNC machines. CNC stands for Computer Numerical Control. A G00 code tells the machine to move fast to a different position. This motion is quick and not used for slicing hard or soft materials. It gets the machine into the right place to start rather than working.

The rapid move command moves the tool from one point to another without cutting the material. The movements are done at the highest speed possible. Therefore, no feed rate is required for the rapid move commands. It requires location coordinates in the X axis, Y axis, and Z axis.

With G00, every portion of the CNC machine proceeds in a straight line to the following position together. G00 conserves time and allows for swift movement of the machine from one job site to another. Since it’s not cutting anything, this is a quick and safe way to get the tool in place.

G01 – Linear Interpolation

CNC G code is a language used to control CNC equipment. So, G01 command is used for cutting, and the machine moves much slower and more carefully. While the G00 command is used for rapid motion without cutting. When you want the machine to cut into whatever material it’s working on a straight line, G01 is for you.

Linear interpolation moves the tool from one point to another in a straight line. The speed is according to a feed rate specified by ‘F’ in the G01 command block.

G01 commands to move in a straight line to the given coordinates. The feed rate refers to the velocity of the moving parts. The feed rate is important since it determines how quickly the machine moves. The cut can be rough or even damage the tool if the feed is too fast.

But if it’s too slow, the completion will take longer. G01 is excellent for performing smooth, precise cuts when you require accuracy. This ensures that the generated components are clean and accurate.

G02/G03 – Circular Interpolation

The G02 and G03 commands in CNC programming are used when the machine is required to move in circles or curves. These commands facilitate the correct movement of the tool along a circular path. It is beneficial for creating round shapes or holes.

The G02 makes the machine move in a clockwise direction. The G03 moves it counterclockwise. The CNC machine needs more information about the starting and ending points. It needs the location of the center of the circle when using these commands. It is depicted by two unique letters: I for the course of the X-axis and J for the course of the Y-axis.

Instead of a straight line, G02 commands the cutting tool to cut in an arc in the clockwise direction. It requires a feed rate specified by the value ‘F’. It requires the specification of the center point (I, J, K) or the radius (R) of the arc. Same as G02. Instead of a clockwise direction, it cuts an arc in the counterclockwise direction.

Also, note that the start of the circle is determined by where the last movement ended. So the last cut had better have been done right. G02 and G03 allow the machine to create smooth, accurate curves and circles on various parts. With the correct information followed by G02 and G03, you can get circular cuts or good curves.

Common M Code Commands in CNC Programming

M-code commands can control those aspects of the machine that are not moving. If G code for CNC make the machine move or cut, the M-codes do the “stuff.” These functions might involve switching areas of the device on or off (the spindle). It alters the tool, ensuring the safety and stability of the device.

M-codes also assist by activating the machine’s coolant. It also helps in opening and closing the machine’s doors while cutting. There’s a whole slew of M-codes, and each one does a certain thing. M03, for instance, turns the spindle on, and M05 turns it off. Some M-codes ensure the material and tool are cool while cutting.

It is in integration with G-Code. Generally, M-code doesn’t work in isolation. It functions in tandem with the G-code to form a comprehensive. M-codes are extremely significant, but they are not present on the same line as the G-codes.

This involves directing the CNC machine’s actions with specific codes. These codes are usually written in a particular sequence and format based on the requirement of the particular CNC machine used.

This keeps the programming simple to read. M-codes can be used slightly differently by different machines. This implies that you should always check the manual. M-codes govern every action that must be taken to ensure the machine operates correctly.

M03/M04 – Spindle Control

It is an M function related to the spindle on a CNC machine. The spindle is the part of the machine that holds the cutting tool and spins it. Using the M03 and M04 commands, they instruct the spindle to start spinning in one of the two directions.

M03 will spin the spindle clockwise. Most cutting tools are built to cut in this direction, which is the most common orientation. M04 causes the spindle to spin in the reverse or counterclockwise direction. You won’t use M04 very often, but it’s occasionally required for some cuts or tools.

S is used to set the spindle speed as well. For instance, the S1000 will spin the spindle at 1000 revolutions per minute (RPM). So, if you want the spindle to rotate clockwise at 1000 RPM, you would write M03 S1000. These commands matter as the spindle performs very well if directed to move.

M06 – Tool Change

The M06 command is used when the CNC machine switches tools to perform another task. Different tasks require various tools, such as drilling, cutting, or shaping. The M06 command tells the machine to stop and change tools when it’s time to switch.

The M06 command is a big time-saver since it allows the machine to automatically swap out tools. This makes the process easier and quicker. It also ensures the job is done step-by-step using the right tool to yield a good result.

M30 – End of Program

In CNC programming, the M30 command indicates the end of the program. The M30 command tells the machine that the job is done when the machine has performed everything. The CNC machine will reset itself after the M30 command is used. It needs to do this to start a new job or a different program.

This is essential as it ensures the CNC machine is set up correctly. The M30 command tells the machine that the job is accomplished. It should go to the next job without any issue.

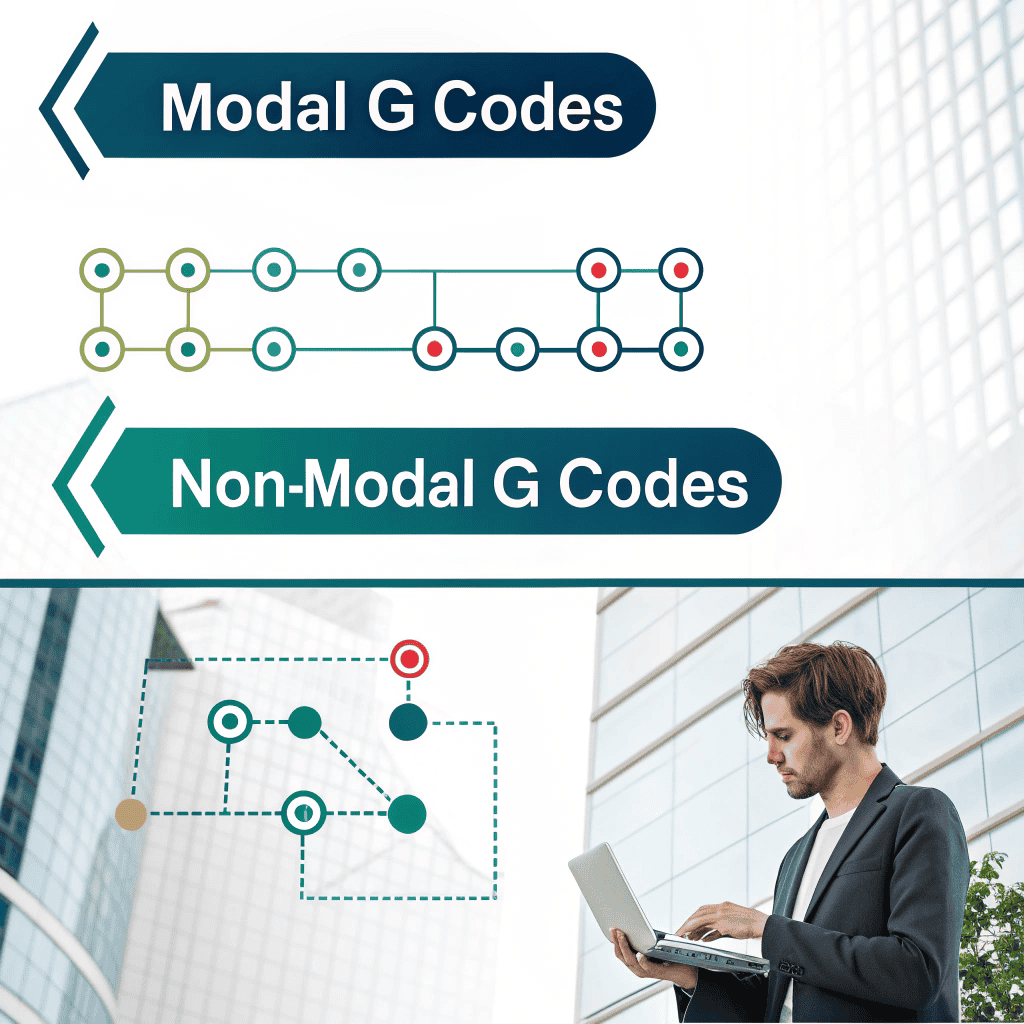

Modal vs Non-modal G Codes

Modal and non-modal describe how long the G-code will affect the machine and how it will control it. They remain active until overridden by a different modal command. For example, if you write G01 in your operating instructions. The machine will cut in a straight line. It will keep cutting straight in that direction until you tell it to do something else using a new G-code.

There are shortcut codes to set many things. These codes do not need to be repeated for every line of the program. Because once you set a modal G-code, it is active until you change it. This simplifies and expedites the program. Because you do not need to write commands on every line.

They only apply to one single line or block of the program. After that line, the non-modal G-code is no longer effective. For example, G04 makes the machine pause, but once that line is done, the pause is done. If you want it to pause much later, call the G04 command again.

Knowing the difference between modal and non-modal G-codes helps control the CNC machine. Modal codes will continue to apply until they are altered. The non-modal codes only refer to the one line in which they exist.

Subprograms and Macros

Subprograms and macros help ease coding and improve performance. A subprogram is a program within a given program. You can create a subroutine to perform some action. Actions like drilling holes, and then invoke it whenever you need to drill holes. That way, you do not have to repeat the same code repeatedly, saving time.

The beauty of subprograms is that when you want to change a single aspect of your code. You have to do so just once, and it will take effect wherever you use that subprogram in your program.

Macros are essentially special tools that enable you to use several records and math in your app. Macros are useful for providing a more appropriate fit. It is between the program level and different components’ abstraction levels.

M98, M97: External and Internal Subprograms:

M98 calls an external subprogram in a separate file with code. M97 calls an internal subprogram in the same file as your main program. Using subprograms and macros makes your it neater, shorter, and more easily modified.

Safety Considerations in CNC Programming

When programming on a CNC machine tool, safety is always the priority for the person. G-codes and M-codes determine the functionalities of the machine. If these codes are not properly coded, it can lead to safety issues.

One example is the breakage of tools. This applies when the G code for CNC fails to control the tool path. The tools may move through the material too quickly or in an incorrect direction. It can cause breakage or damage.

This is dangerous because if it breaks, you can damage the machine and/or the material you are working on. Also, programming errors can allow the machine to move to arbitrary places in code. It can crash the machine and create hazardous events.

To avoid these issues, examine your code to understand which path it will follow. Simulate the code before you start machining. Thus, you can find any mistakes and prevent an accident. Additionally, inspect your G-code for the tool offsets.

It indicates how the tool is situated about the machine, and work offsets. It specifies the location of the material in the machine. CNC programming becomes safer and more efficient by verifying the setup and offsets.

Using CAD/CAM Software for CNC Programming

CAD/CAM software aids in linking digital designs with their physical counterparts. CNC programming is quicker and more efficient with such solutions. As they ensure compatibility between the digital designs and the physical objects. Computer-aided design is used to create detailed digital drawings and 3D models.

These drawings are very important because they show what a CNC machine needs to create. AutoCAD is a popular CAD tool that assists with creating 2D designs, which can be used for several CNC tasks. Other free options, including FreeCAD, enable people to develop basic designs. But they may lack all the advanced options required for more complex CNC work.

CAM converts your CAD designs into G-code. Note that some CAD programs (e.g., Fusion 360) combine CAD and CAM in a single program. so the same CAD is used to generate a model to be milled or printed that will then be sent to an attached CNC machine. It allows you to design the part and generate G-code all in the same software.

CAM tools convert the 3D designs created in CAD software into the G-code that the CNC machine can use. G-code gives the machine instructions on how to cut, move, or shape the material. Most CAM programs offer some CAD components; however, not all have the tools of a full CAD program.

Simulation tools are incorporated in many CAD/CAM programs to prevent errors. They allow you to simulate your programming in a virtual environment to catch bugs early.

Advanced CNC Programming Techniques

Advanced CNC coding methods allow quicker speeds, greater precision, and complex part production. High-speed, multi-axis, and adaptive machining are some of these techniques.

High-speed machining is a technique that enables the CNC machine to remove material. It saves time and makes the machine more productive.

Multi-axis Machining is a process that adds movement to a conventional machine tool along the X, Y, and Z axes. Additional rotating axes add more movement directions to the CNC machine. It is manufacturing complex shapes, such as curved or inclined surfaces.

Adaptive machining is when a system adapts to changes. These are based on real-time input to refine the cutting process. It helps to ensure the machine runs better and faster by keeping it at optimal settings.

Many advanced CNC programs have simulation tools. It allows to simulate the CNC program on a computer before the real machine. Such simulation tools aid in early error detection. It is streamlining the accuracy and minimizing errors in the process. In general, state-of-the-art CNC technology increases the speed, flexibility, and complexity of machining.

Popular CNC Programming Software

How many best CNC programming software tools that can make CNC machining easier and more useful?

Autodesk Fusion 360 is one of the most popular and widely used software tools. It helps make very tricky shapes and movements. This software works with CNC machines that move in 3 to 5 directions.

Fusion 360 is also great at putting shapes together on a flat sheet of material, called nesting. It also helps with things like 3D printing using metal. Fusion 360 includes both designing tools (CAD) and coding tools (CAM) in one program, which is why so many people like using it.

Another well-known tool is Cura. Most people use it for 3D printing, but it can also help with CNC coding. Cura shows each layer the machine will work on, so you know what the machine will do step by step.

It has an easy-to-use screen and lets you change settings as needed. If you need the machine to build extra parts for holding something up while printing, Cura can do that too. These top software tools are smart. They help make CNC programming easier and faster by giving you the right tools to use on your computer.

Real-World Applications of G-Code in CNC

G-Code is used in many CNC machines to help them move and make parts. G-Code helps the machine move the same way each time so it makes parts that match the plan. This code is used in different ways in real-life CNC machines.

Milling: G-Code is used to control a machine that has spinning cutters. These cutters touch the material and remove parts of it. G-Code tells the machine where to move the cutter, how fast to spin it, and how deep to cut. It helps make things like gear wheels and engine parts.

Turning (lathe): Turning is done with a machine called a lathe that spins the material while it is cut into shape. G-Code controls how the material spins, how the tool moves, and how fast it turns. It helps make round parts like cylinders and rods.

Drilling: G-Code tells the machine where to make holes in a piece of material. It tells the machine where the hole should go, how deep it should be, and the angle it should be drilled. This is needed when making holes in metal, wood, or plastic.

Laser/Plasma cutting: These machines use laser beams or hot plasma to cut materials. G-Code tells the machine how to move the laser or plasma tool. It also tells it how fast to move and how strong the cut should be. This is often used to cut metal sheets into different shapes.

Contact Us

Looking for CNC machining service solutions? Contact Hanke Construction Machinery Manufacturing Co., Ltd for expert support and high-quality CNC machining services.

Final Lines

G-code and M-code are used to do the jobs for CNC machines. M-codes govern aspects like the spindle and tool changes, while G-codes tell the machine how to move and cut. The use of these codes must be done with caution to remain unscathed and produce properties correctly.

A few codes speed up or slow down the tool; others allow you to make circles or switch tools. Software (Fusion 360, Cura) helps to plan the work and check mistakes. Based on CNC codes and their usage, you can create sturdy and effective items from the machines.