Metal parts get dirty. Rust, paint, and oil can stick tight. Factories must clean these parts before they build, weld, or paint them again. Two big ways to do this are laser cleaning and sandblasting. People often ask, “Laser Cleaning vs. Sandblasting— which is better?”

Picking the right method matters. The wrong choice can scratch the part, waste money, or harm workers and the planet. A smart choice gives you a smooth finish, saves time, and meets safety rules.

In this guide, you will learn how each method works, what it costs, and when to use it. By the end, you can decide which surface treatment fits your job best.

Understanding the Two Methods

What is Laser Cleaning?

Laser cleaning, a form of laser ablation, is a method of removing a selective layer of material from a surface using laser energy. The laser cleaning process utilizes photonic energy to peel off, vaporize, sublimate, or burn away unwanted waste material without causing harm to the underlying bulk material.

In most laser materials processing applications, a focused beam forms a relatively small spot on the target material. Laser cleaning is no exception despite typically being used over a relatively wide area. Laser cleaning uses a technique known as laser scanning, which rapidly directs or “scans” a laser beam along a path or across a wider zone. This means that the laser only interacts with targeted material for a fraction of a second at a time.

Common uses of laser cleaning include:

- Removing rust from old machine parts

- Stripping paint from cars or airplanes

- Cleaning mold or dirt off tools

- Getting rid of grease before welding

Laser cleaning is fast, clean, and safe for many industries, especially ones that need high precision, like aerospace, medical tools, or electronics.

What is Sandblasting?

Sandblasting, sometimes known as abrasive blasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants. A pressurised fluid, typically compressed air, or a centrifugal wheel is used to propel the blasting material.

Types of sandblasting include:

- Dry blasting: Just air and grit

- Wet blasting: Uses water to reduce dust

- Soda blasting: Uses baking soda—gentler on surfaces

- Bead blasting: Uses tiny glass beads—good for smooth finishes

Common uses of sandblasting include:

- Cleaning large metal surfaces

- Removing heavy rust

- Preparing metal for painting or coating

- Texturing surfaces for better grip

Sandblasting is great when you need fast, low-cost cleaning on tough or big parts. But it creates more dust and mess than laser cleaning.

Comparison: Laser Cleaning vs. Sandblasting

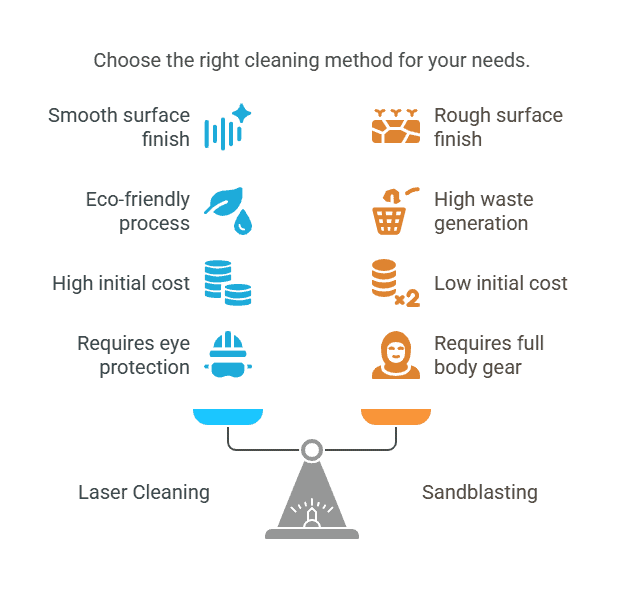

Surface Quality & Precision

Laser cleaning gives a clean and smooth surface. It works well on small details and delicate parts. It doesn’t scratch or wear down the metal. That’s why industries like aerospace or medical tools prefer laser cleaning. The laser can be set to remove just a thin layer without touching the clean part underneath.

Sandblasting is rougher. It scrapes off rust or paint fast, but it can leave marks. If the metal is soft or thin, sandblasting might damage it. However, if you want to roughen a surface before painting or gluing, sandblasting is helpful.

Surface finish summary:

- Laser cleaning: smooth, gentle, great for fine work

- Sandblasting: rough, fast, better for heavy-duty jobs

Environmental Impact

Laser cleaning is more eco-friendly. It doesn’t use chemicals or make a lot of waste. The laser turns dirt into dust or smoke, which is easy to catch with a filter. No sand or grit is left behind.

Sandblasting creates a lot of dust and waste. You need to collect and clean up the used grit. Sometimes, it uses chemicals or water, which adds to the mess. It can also be bad for workers if they breathe in the dust.

Environmental summary:

- Laser cleaning: clean, safe, no chemicals

- Sandblasting: messy, dusty, more waste

Cost & Operational Efficiency

Laser cleaning costs more upfront. The machines are expensive. But once you have the equipment, it needs less maintenance and no extra materials like sand or water. It also needs fewer workers.

Sandblasting equipment is cheaper to buy, but you need to keep buying blasting media (like sand, soda, or beads). You also need more cleanup, which takes time and labor.

Cost summary:

- Laser cleaning: high setup cost, low running cost

- Sandblasting: low setup cost, high running and cleanup costs

Safety Considerations

Laser cleaning is safer for the environment, but it still needs care. The laser is very powerful. Workers need special goggles, shields, and training to stay safe. The laser light can burn skin or damage eyes if misused.

Sandblasting can be dangerous to health. The dust can go into the lungs and cause breathing problems. Workers must wear full-body suits, masks, and gloves. There’s also a risk of silicosis, a serious lung disease from breathing fine dust.

Safety summary:

- Laser cleaning: needs eye protection and shielding

- Sandblasting: needs full gear, high health risk from dust

When to Use Each Method

Laser Cleaning: Best Use Cases

Laser cleaning is great for jobs that need gentle, accurate cleaning. It works well when you don’t want to damage the surface under the rust or paint. It’s also helpful when working on delicate or small parts.

Use laser cleaning if:

- The surface has thin dirt or rust

- You’re cleaning soft metals or sensitive surfaces

- You work in high-tech industries like:

- Aerospace (airplane parts)

- Electronics (circuit boards)

- Medical tools (surgical equipment)

Laser cleaning is also good for automated systems. You can set up the machine to work without needing someone to blast or scrub by hand. That saves time and makes the process safer.

Sandblasting: Best Use Cases

Sandblasting is better for hard and dirty jobs. It’s strong and fast. It removes heavy rust, paint, or thick buildup. It’s also used when you want to make the surface rough so paint or glue sticks better.

Use sandblasting if:

- The metal has thick rust or heavy coatings

- You need to treat large surfaces quickly

- You want to texture a surface for coating

- You need a low-cost solution for a one-time job

Sandblasting is often used in:

- Shipyards (cleaning large metal parts)

- Construction (preparing steel beams)

- Auto shops (cleaning car frames)

Key Factors to Consider When Choosing

Choosing between laser cleaning and sandblasting depends on your needs. Below are the key things to think about before you decide:

1. Budget

- Laser cleaning costs more to buy. But over time, it saves money because it doesn’t need sand, water, or lots of labor.

- Sandblasting is cheaper at first. But you’ll spend more on sand, gear, cleanup, and safety equipment.

Tip: If you have a high budget and want long-term savings, laser is better. If your budget is tight and it’s a short project, sandblasting works.

2. Material Type and Surface Finish Required

- Use laser cleaning if the material is soft, thin, or must stay smooth.

- Use sandblasting if the surface is strong and you don’t mind a rough finish.

Some jobs need a smooth finish. Others need a rough texture for paint to stick. So think about how you want the surface to look after cleaning.

3. Production Volume and Speed

- Laser cleaning is good for small batches or precise work. You can even automate it for fast jobs.

- Sandblasting is great for big jobs and large surfaces. It’s fast and covers more space at once.

If you’re cleaning a lot of parts or working on a tight deadline, sandblasting might be faster—if you have a good team and setup.

4. Regulatory or Environmental Compliance

- Laser cleaning is cleaner and safer for the planet. It creates little waste and meets many environmental rules like OSHA and ROHS.

- Sandblasting creates dust and waste, which can break rules if not handled well.

If your workplace follows strict safety or eco rules, laser cleaning is the better choice.

Expert Recommendation

Still unsure which method to choose? Here’s a simple chart that compares laser cleaning and sandblasting side by side:

| Factor | Laser Cleaning | Sandblasting |

| Surface Quality | Smooth, precise, gentle on surfaces | Rougher finish, can damage soft materials |

| Best for | Light rust, sensitive parts, high-precision | Heavy rust, big areas, rough surface prep |

| Cost | High setup cost, low ongoing cost | Low setup cost, higher long-term cost |

| Waste & Cleanup | Minimal waste, easy to filter | Lots of dust and used grit to clean up |

| Safety | Needs laser goggles and shields | Full protective gear required |

| Environment Friendly | Yes – clean process, no chemicals | No – dusty, uses abrasive materials |

| Speed | Slower for large jobs unless automated | Fast for large areas |

| Ease of Use | Needs training, easy to automate | Easier to start with, but messier |

What Do Experts Say?

- Choose laser cleaning if your work needs clean results, safety, and precision, especially in industries like aerospace, electronics, or medical.

- Choose sandblasting if you need fast, low-cost cleaning for tougher surfaces or large jobs in industries like construction or auto repair.

Both methods are good, just for different jobs. Always match the method to your surface, job size, and safety rules.

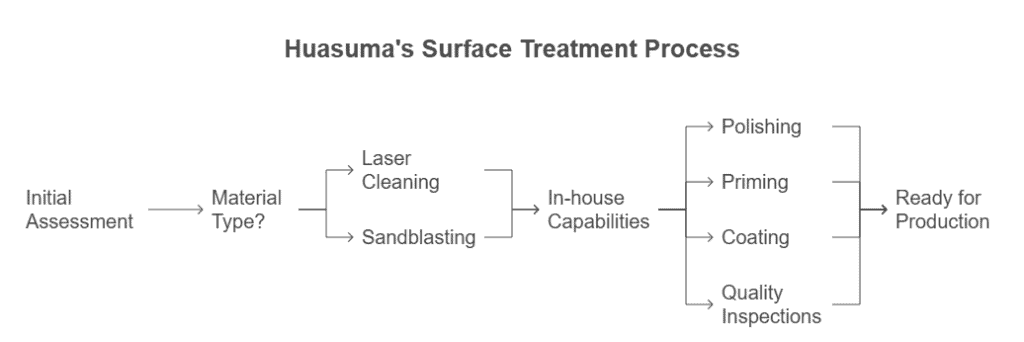

Why Huasuma Is Your Go-To Partner for Surface Treatment

When you’re evaluating laser cleaning vs. sandblasting, it’s important to have an experienced partner who understands both methods deeply, and knows exactly when and how to use them. That’s where Huasuma (Huashun Machining Co., Ltd.) comes in.

Here’s how Huasuma supports your project:

- We offer both advanced laser cleaning and traditional sandblasting as part of our full-service metal fabrication lineup, including casting, forging, CNC machining, and finishing.

- With our state-of-the-art factory in Xuzhou, Jiangsu, China, and a team of seasoned engineers, we tailor the right surface treatment method based on your part’s material, size, and required finish.

- We help guide decisions like:

- Soft / precision components → often best with laser cleaning

- Heavy-duty or large surfaces → typically suited to sandblasting

- Our in-house capabilities—such as polishing, priming, coating, and quality inspections using spectrometers and CMMs—ensure your parts are not only cleaned, but ready for next-stage production.

Parts sandblasting #casting #manufacturing #machine

How does this benefit you?

- Save time and money by choosing the best cleaning method from the start.

- Avoid mistakes—no wasted materials or over-processing.

- Ensure quality with a partner who handles everything from design through delivery.

If you’re exploring laser cleaning or sandblasting for your parts, Huasuma is here to help. We welcome questions, sample reviews, and quick consultations—just let us know what you’re facing, and we’ll provide a tailored recommendation.

Frequently Asked Questions (FAQs)

1. Is laser cleaning better than sandblasting?

Laser cleaning is better for smooth finishes, small parts, and eco-friendly work. It’s gentle and clean. But sandblasting is better if you need to remove heavy rust or dirt fast, especially on large metal surfaces. So, the better method depends on the job.

2. Can laser cleaning replace abrasive blasting entirely?

No, not always. Laser cleaning works great in many cases, but sandblasting is still better for thick buildup or rough texturing. Some industries may use both methods depending on the task.

3. What materials can be treated with laser cleaning?

Laser cleaning works on many materials, like:

- Steel

- Aluminum

- Copper

- Brass

- Stone

- Painted surfaces

It’s best for solid, non-transparent materials. It’s not ideal for very dark rubber, glass, or plastics unless tested first.

4. Is laser cleaning eco-friendly?

Yes. Laser cleaning uses no chemicals or sand, makes very little waste, and creates no dangerous dust. It’s one of the most environmentally friendly cleaning methods used in industry today.

5. What are the risks of sandblasting?

Sandblasting can be risky if done without safety gear. The dust can hurt your lungs, and flying grit can injure eyes or skin. Workers must wear masks, gloves, and full suits. Also, if silica sand is used, it can cause silicosis, a serious lung disease.

Conclusion

Laser cleaning and sandblasting are both strong tools for cleaning and preparing surfaces. But they are made for different needs.

- Laser cleaning is best for clean, precise, and eco-safe jobs. It protects surfaces and workers, even though it costs more at the start.

- Sandblasting is best for heavy-duty, large-area work. It’s fast and cheaper to begin with, but messier and less safe.

Each method has its place. Your best choice depends on your budget, material, safety needs, and project size.

Still not sure which method is right for your job?

Contact us today for a free consultation. Our experts will help you choose the best surface treatment method for your needs—whether it’s laser cleaning, sandblasting, or both.