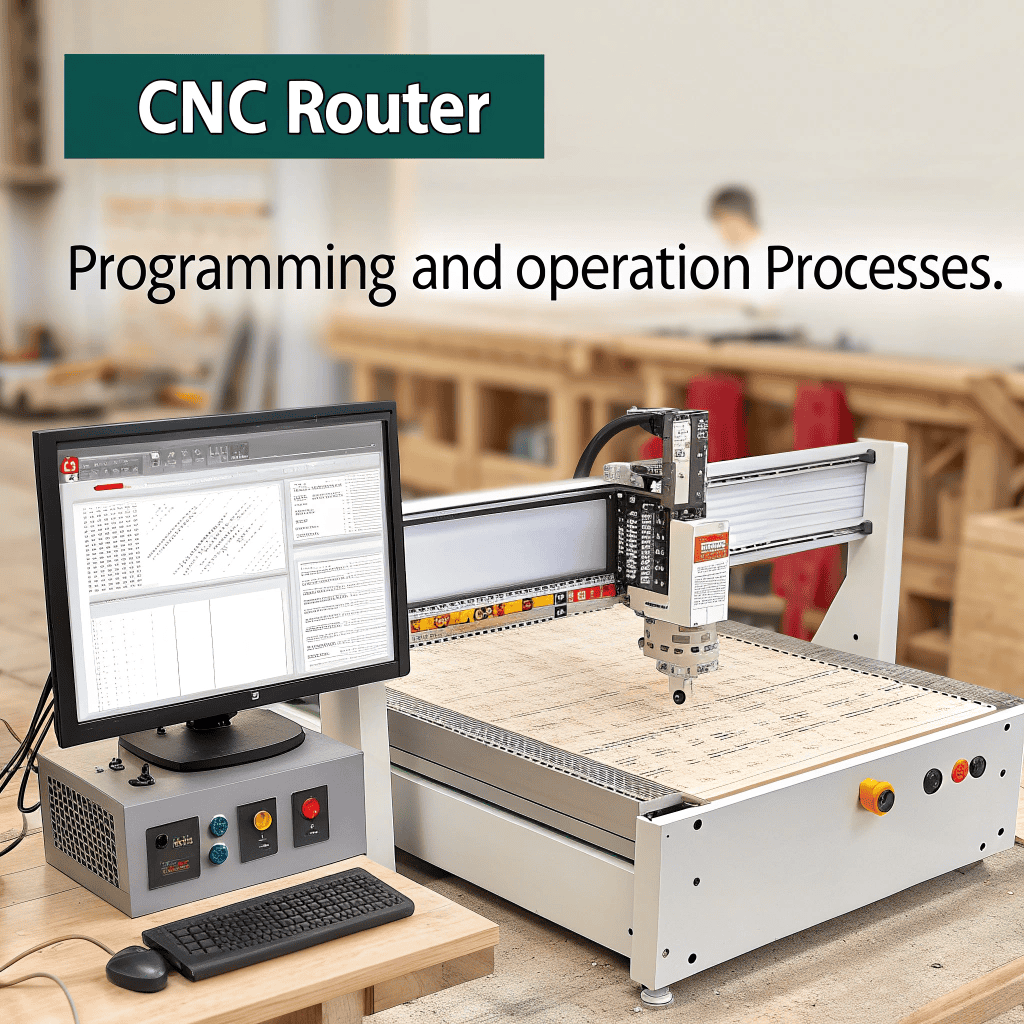

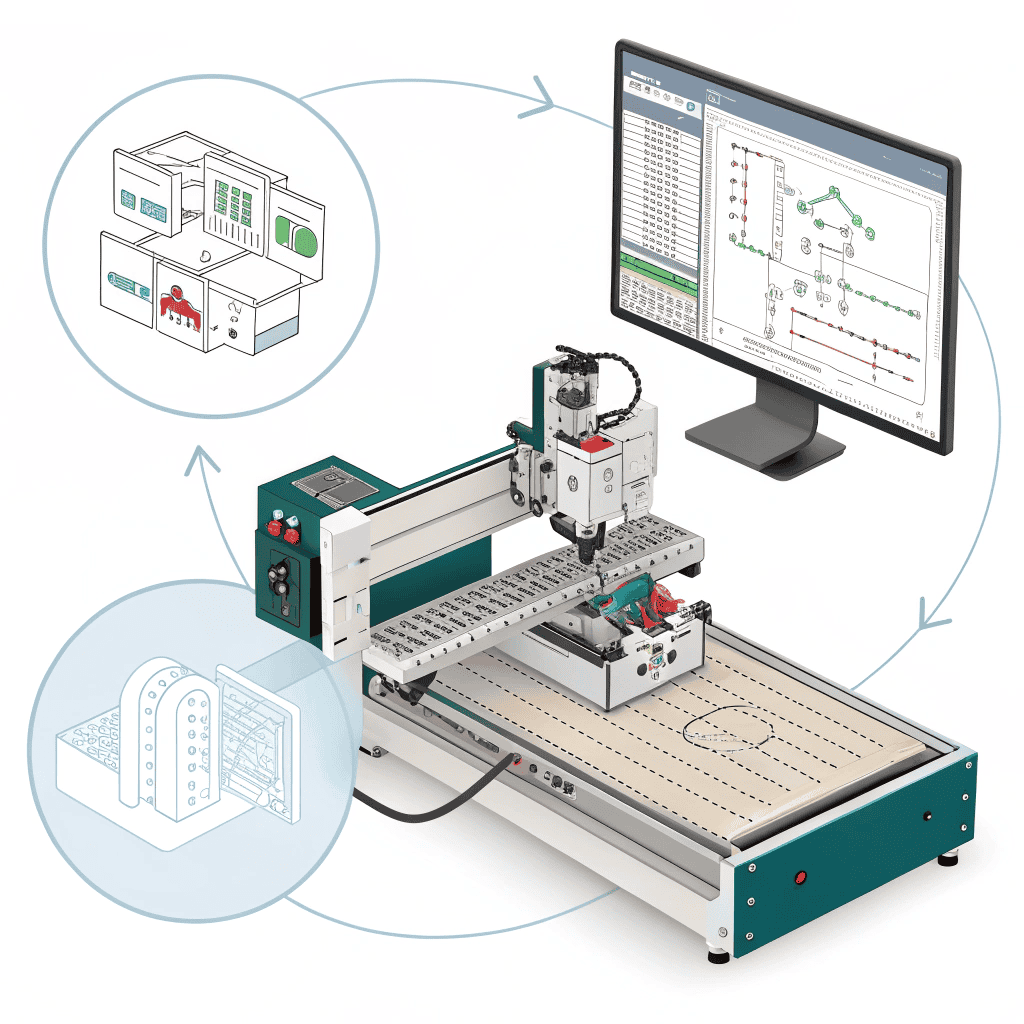

How to program a CNC router? A CNC router is a computer-operated machine that precisely cuts, shapes, and engravings wood, plastic, and metal. It begins by designing a project on CAD software, which dictates the shape and size of the project.

It is then programmed in the CAM software and transformed into G-code – a read G-code to a CNC. The G-code tells the router exactly where to travel, how far to travel, and how to get there.

The workpiece is placed onto the router bed for machine machining, a proper cutting bit is placed, and the origin of the direction of the tool is set. If loaded and programmed by the G-code, the CNC router will run the program automatically in a cycle to complete the work.

After machining, the product is cleaned and checked when necessary. The process is accurate and can be replicated in any quantity of uses.

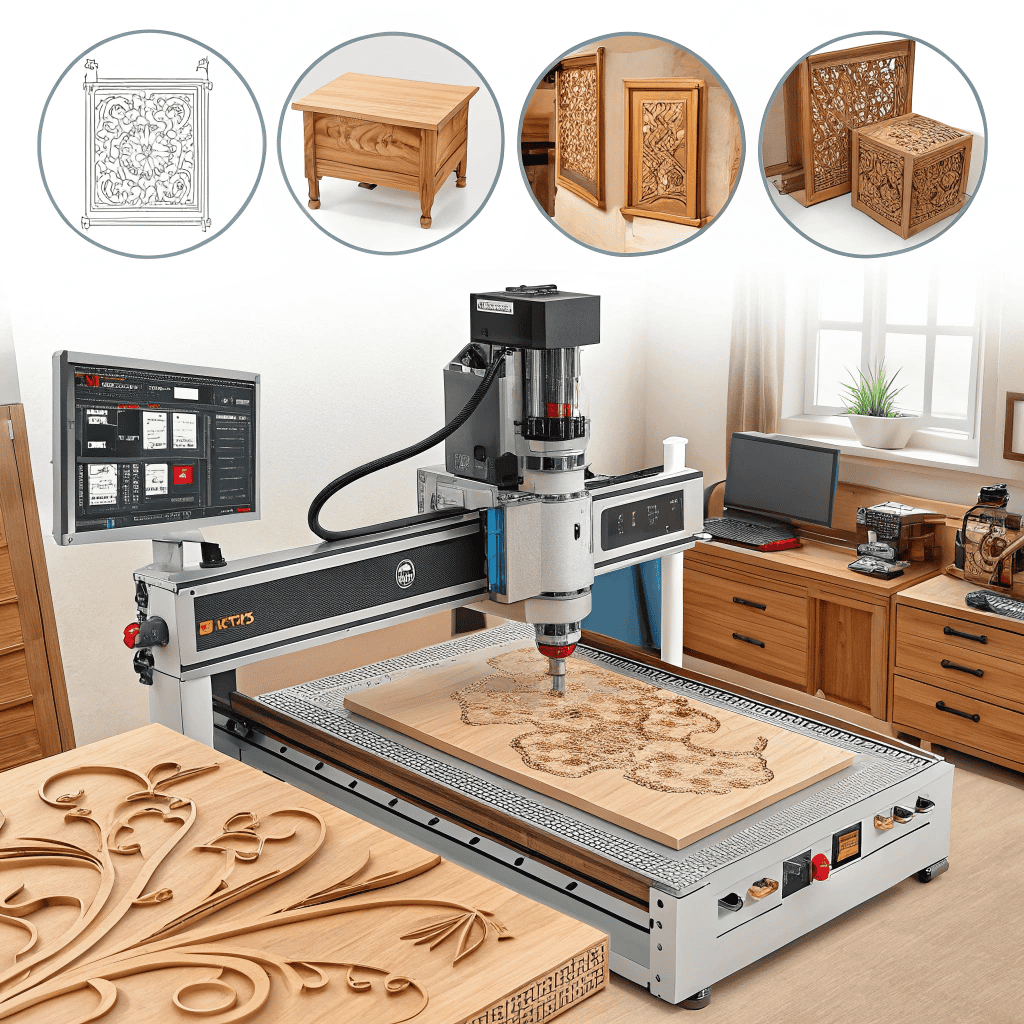

Brief overview of CNC routers in woodworking

CNC routers are widely used in woodwork. They deliver precision and accuracy in cutting, carving, and wood shaping. CNC routers can be used to create complex designs, custom furniture components, cabinets, and signs. CNC routers implement programmed instructions. This way the wood craftsmen can achieve accurate and repetitive operations.

Using CAD and CAM software, the designs are entered into the computer and programmed into G-code. The machine can easily cut complex designs and varying tool paths, using less time and material wastage. CNC routers are now an everyday item in modern woodworking workshops for professionals and hobbyists alike.

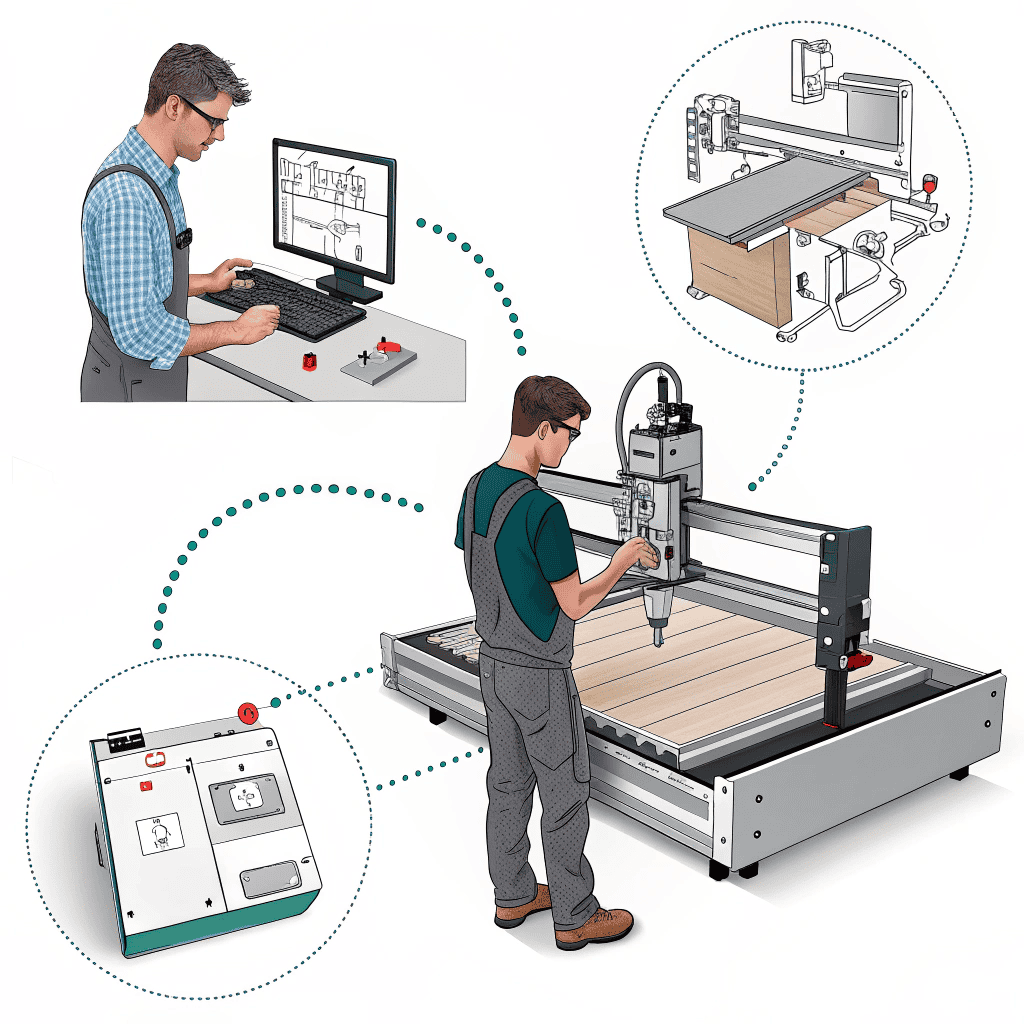

Students will be guided to configure, program, and operate a CNC router step by step. They will be guided through crucial setup procedures to produce precise and safe woodwork.

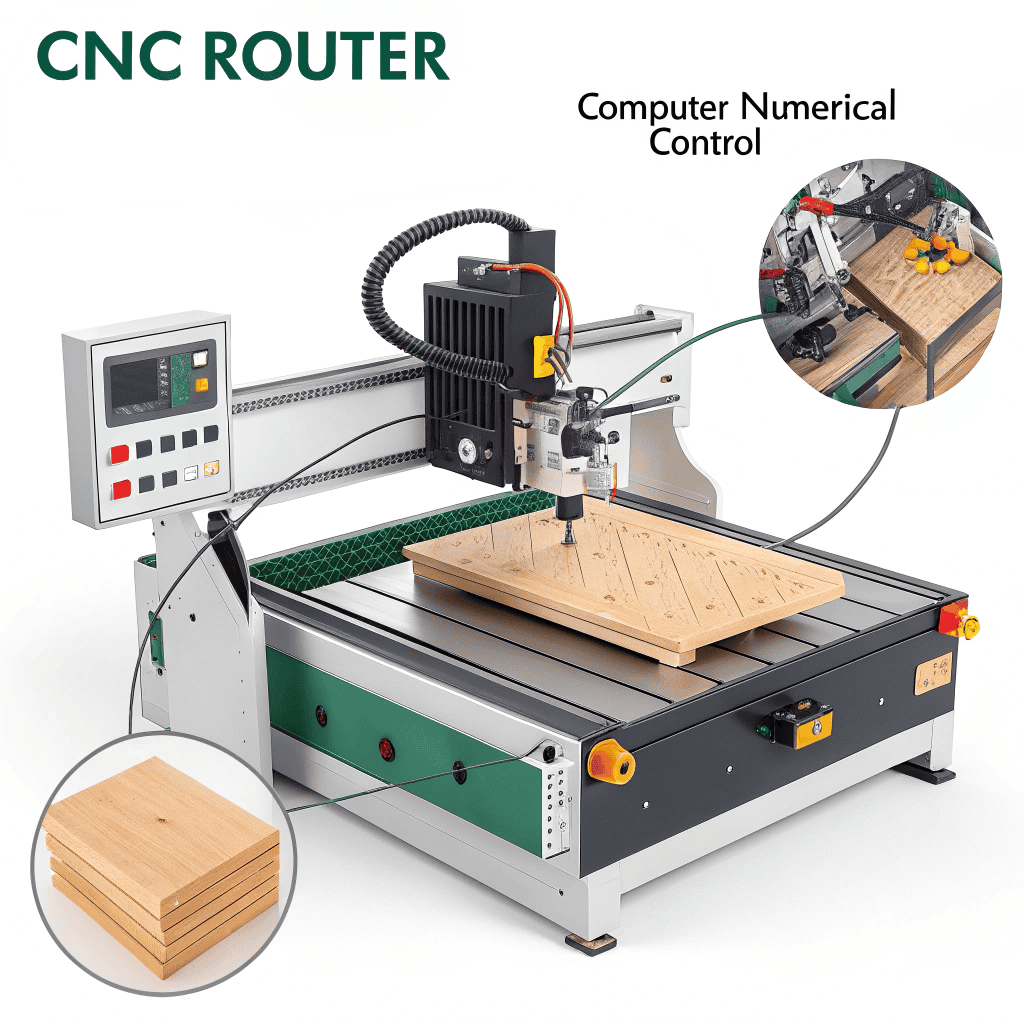

What is a CNC Router?

A CNC router is a computer-controlled cutting machine to cut, engrave, and trim plastic, metal, and wood. It produces precise cuts using pre-programmed instructions (G-code). It then replicates cuts for making, woodworking, and designing.

How it Works

A CNC router accomplishes this by running computer programs to control a cutting tool along axes. It starts in a CAD file and becomes converted into a toolpath using CAM software. The router then proceeds with the design onboard. It controls the cutting tool to accurately cut or engrave the material.

Key Components (spindle, bed, control system)

Spindle: The high-speed cutting bit used to shave or trim material.

Bed/Table: Horizontal working surface where the material is fed and held stationary. It holds and secures the workpiece engaged.

Control System: Electronics and computer inputs and G-code processing govern the movement of the machine along the X, Y, and Z axes.

Together, all these are responsible for precision, stability, and operational efficiency in cutting or engraving.

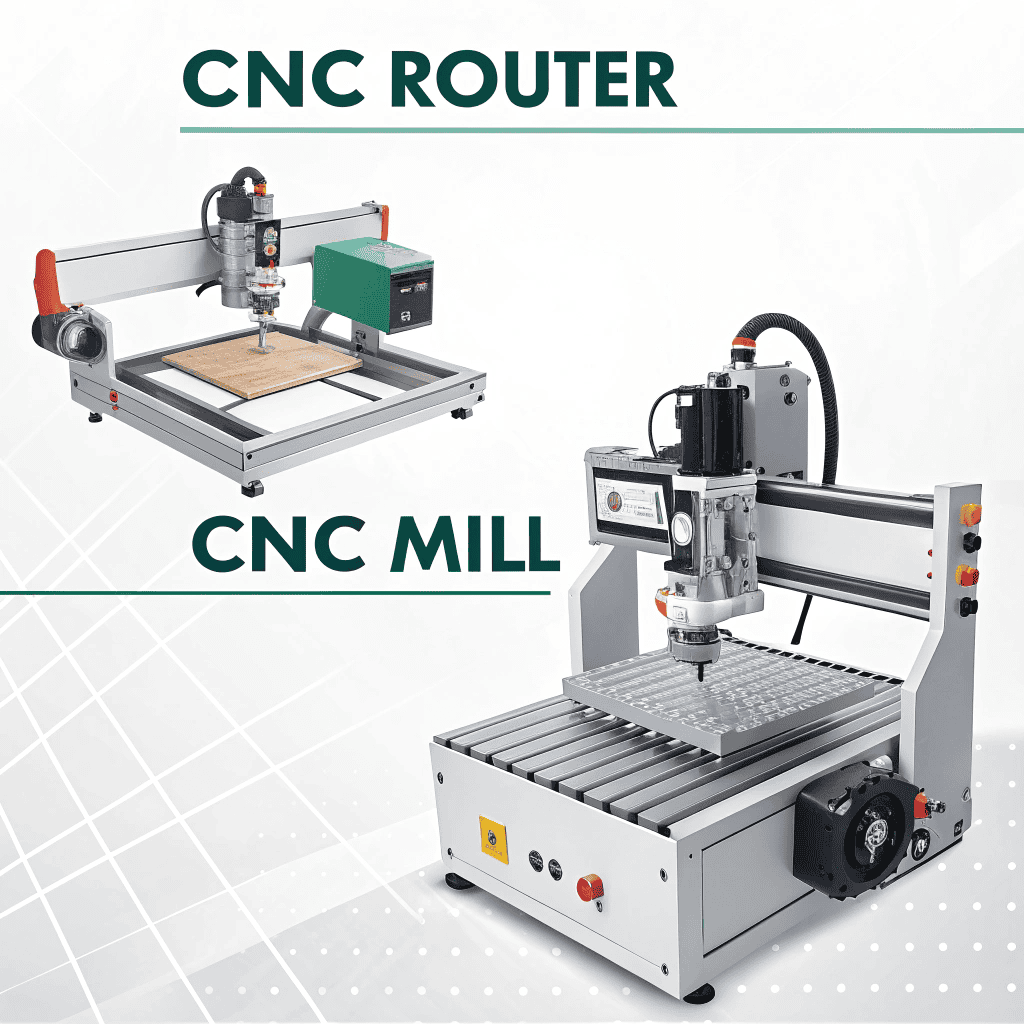

Difference Between CNC Router and CNC Mill

The most salient difference between a CNC mill and a CNC router is based on design, cutting speed, and material.

CNC Routers are used for soft materials like wood, plastic, and foam. They have faster cutting speed. They are best suited for flat-sized and large-sized workpieces and detailed designs.

CNC Mills are meant for thicker materials such as metal and are built to be rigid and stiff. They are slower-cutting but more precise and deeper. Therefore, they are ideal for detailed metal fabrication and heavy use.

Working Principles and Software

CNC routers use X-, Y-, and Z-axis movements to position the cutting tool relative to the workpiece. The tool moves across the workpiece’s surface, cutting or engraving the material. CNC routers are available in various sizes, providing ample work area for handling sizable materials.

CNC mills operate similarly to their manual counterparts. It utilizes rotary cutting tools to remove material. However, the movement of the cutting tool is controlled by CNC instructions. The cutting tools are rigidly attached to the machine, ensuring a CNC mill can cut even hard materials.

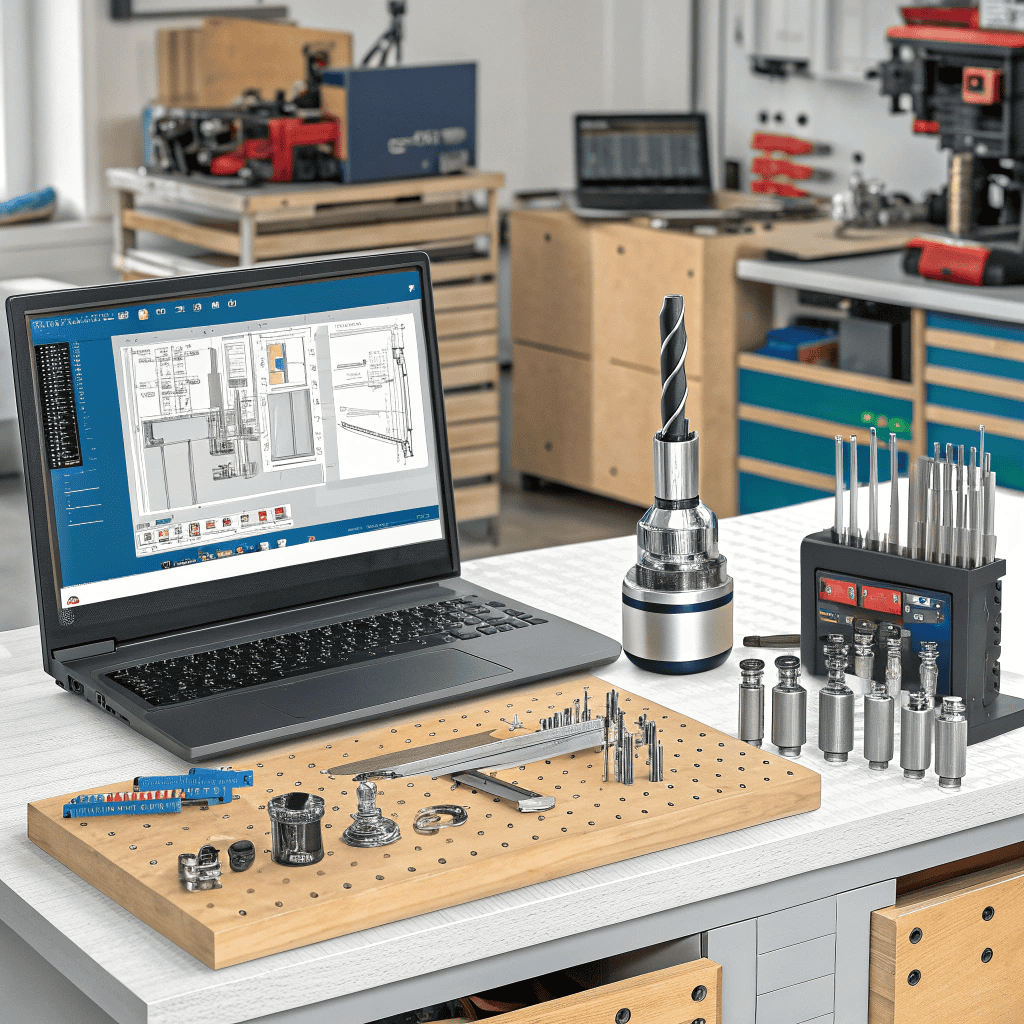

Tools & Software You’ll Need

To get the best out of a CNC router, you will need the following set of software and tools:

CNC Router: The router hardware machinery comprises a spindle, bed, and control.

Cutting Tools: Router bits like flat, ball nose, or V-bits. It depends on material type and cutting style.

Clamps and Fixtures: Clamping holding clamps to hold the material securely on the CNC bed for machining.

Measuring Instruments: Calipers and rulers to measure accurately to avoid the wrong setup.

CAD: Create 2D or 3D project plans (e.g., AutoCAD, Fusion 360).

CAM: Converts CAD files into G-code for the CNC router (e.g., VCarve, Fusion 360 CAM, or Aspire).

CNC Controller Software: Talks to the CNC router to move the machine (e.g., Mach3, UCCNC).

The software and tools communicate with one another to carry out precise and effective routing, cutting, and engraving.

CAD/CAM Software (e.g., Fusion 360, VCarve, Easel)

CAD/CAM software must be used to design and translate models into machine language instructions (G-code) to be interpreted by CNC routers. Some of the popular CAD/CAM softwares are:

Fusion 360: It is a single-software CAD and CAM suite with full-featured capability. In this the user can model 3D models and create G-code for CNC machining. It is used commercially and by hobbyists.

VCarve: Created specifically for CNC routers. VCarve is a popular software with a special affinity for 2D and 3D cutting, engraving, and profiling. Easy to operate and uncomplicated, VCarve is well suited to woodworking. It has ended up in the arsenal of sign makers, furniture makers, and hobbyists alike.

Easel: A simple, browser-based app perfect for new users. Easel simplifies design and CNC routing by integrating CAD and CAM within a single entity. Perfect for a person who requires a simple-to-use interface on small woodwork projects.

These programs simplify the design-to-production process. It allows users to create complex designs and convert them into precise CNC cuts.

G-code Sender (e.g., UGS, Mach3)

A G-code sender is a program that transmits your CAD/CAM program’s G-code to the CNC machine. It executes the machine accordingly. Some of the popular G-code sender software are:

UGS: An open-source, user-friendly G-code sender. It is utilized by everyone on both sides of CNC hardware. UGS provides access to a simple-to-use interface for sending files and machine operation sending. It is very popular with small businesses and hobbyists.

Mach3: A more advanced G-code sender and CNC controller software program that gives tighter control of CNC machines. Mach3 is used for commercial purposes. It supports varied CNC machines, including real-time control, toolpath simulation, and user-definable parameters.

Safety Gear & Materials (wood types)

Choosing materials to work with on a CNC router requires consideration of factors beyond just the desired final part. Different materials are affected in diverse ways by the router, varying by end used and machine settings.

The router itself, especially the end used, is affected by the material. It is important to understand the material options available. It should be able to draw predictions from the behavior of known materials.

Using safety gear and materials with a CNC router g code keeps a person safe. Safety Gears are:

- Safety Goggles: To shield your eyes against dust and debris circulating in the air.

- Hearing Protection: CNC routers make an incredibly loud sound. Therefore, earplugs or earmuffs assist in preserving hearing.

- Dust Mask or Respirator: To avoid inhaling dust particles, especially during wood cutting.

- Gloves: Use protective gloves to handle work materials safely, but do not grip ones by the machine.

- Shop Apron: Long-apron aprons cover your clothes and provide additional tool pockets.

Materials (Wood Types):

- Softwood: Pine, fir and cedar wood are softwoods. They are easy to cut and engrave; hence, they are ideal for beginners and general woodworking.

- Hardwood: Oak, maple, and cherry wood are denser and harder. They provide a silky feel but are precision-based.

- Plywood: For heavy-duty use, plywood is a layered sheet and is stable and durable.

- MDF: Flat and even material known to be heavily used to make precision cuts, models, and signs.

Basic Concepts of CNC Router Programming

As long as you use safety equipment and good materials correctly, you can obtain personal safety and quality results from your CNC routing operations.

The CNC router is programmed in G-code to control the tool path and cutting. You should have some general knowledge of toolpaths, feed rates, and coordinate systems for good, accurate, and precise cuts.

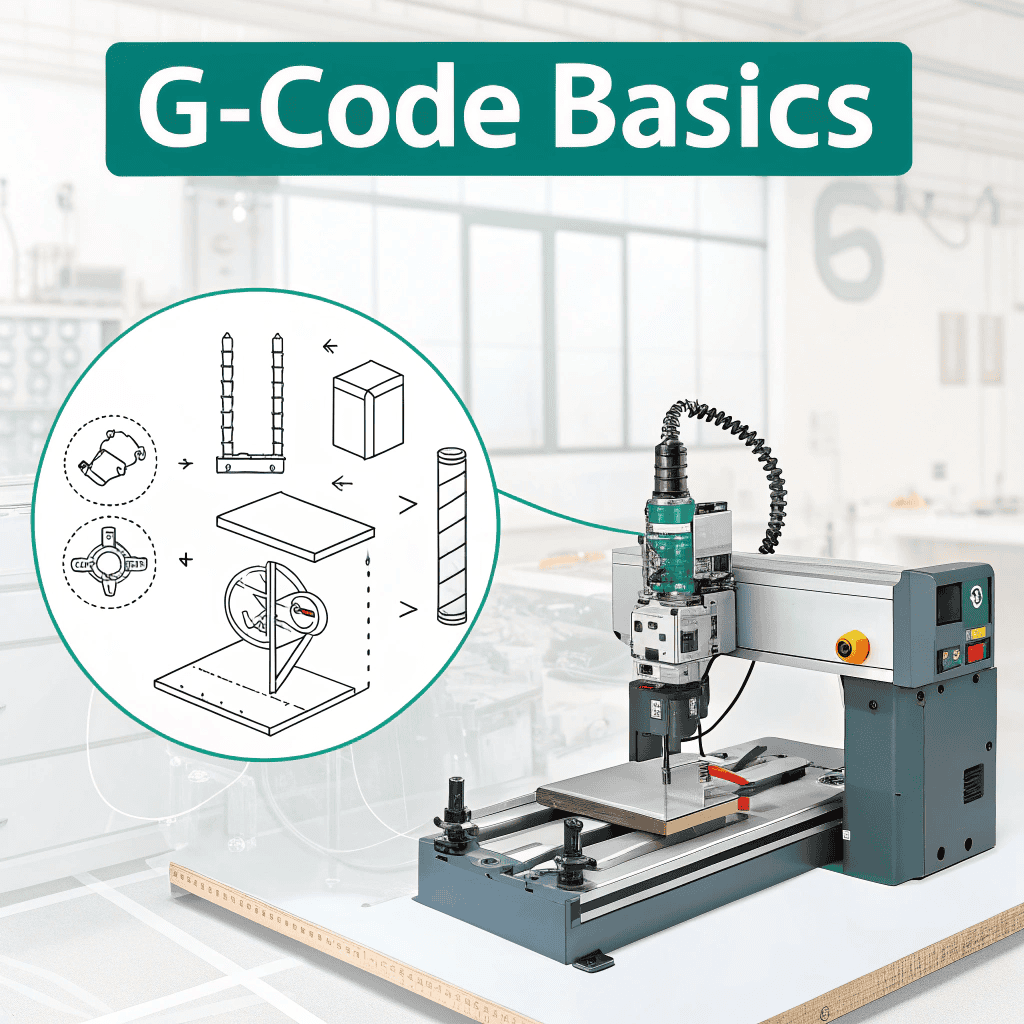

G-code Basics (with examples)

G-code is a CNC machine, i.e., router language. G-code has many instructions that command machine movement, speed, etc. Some CNC router basics instructions and examples are listed below:

1. G0 – Quick Travel

The command makes the CNC machine travel fast to a position without cutting.

- Example: G0 X10 Y5 Z0

It moves the cutter to positions X=10, Y=5, and Z=0 at quick speed.

2. G1 – Linear Cut Travel

G1 is used for a linear cut in a straight line at a programmed feed rate.

- Example: G1 X20 Y15 F100

This puts the tool to X=20, Y=15 cutting with a feed rate of 100 units/minute.

3. G2/G3 – Circular Motion

G2: Circular interpolation in a clockwise direction.

G3: Circular interpolation in a counterclockwise direction.

- Example: G2 X30 Y30 I5 J0

This puts the tool in a circular motion to X=30, Y=30, with an I (X-axis) and J (Y-axis) value defining the radius.

4. G28 – Back Home Move

This will bring the machine back to its home position.

- Example: G28 X0 Y0 Z0

It returns the machine to the starting point (X=0, Y=0, Z=0).

5. G21 – Use of Metric Units

G21 makes the program use metric units (mm).

- Example: G21

This instructs the CNC machine to travel in millimeters for all the movements.

These fundamental G-codes give basic commands to regulate CNC router movements.

Coordinate Systems (X, Y, Z axes)

Coordinate the system upon which a CNC router is programmed. This is to establish the workspace of a machine and where it travels. It is usually established in X, Y, and Z axes.

1. X-Axis:

The X-axis controls the horizontal movement along the workpiece. The movement of a tool along the axis changes its horizontal location.

Example: From X=0 to X=10 means the tool would travel 10 units right.

2. Y-Axis:

The Y-axis drives the up and down movement, moving the tool from back to front along the workpiece. It is at a right angle to the X-axis.

Example: From Y=0 to Y=10, the tool will travel 10 units positive.

3. Z-Axis

The Z-axis controls motion in a vertical axis, which affects cutting depth. It controls the height or lowness at which the tool will travel about the workpiece.

Example: From Z=0 to Z=-5, the tool will travel five units into the material to begin cutting.

Coordinate System Reference Points

- Origin (0,0,0): Where on the coordinate system the point of origin is, typically, the center or workpiece corner. That is where a CNC action will start.

- Tool Offsets: The machine occasionally must alter the tool’s cutting size. Offsets help provide accurate cuts.

With the X, Y, and Z axes, CNC operators can provide precise control of tool travel to provide precise cuts, engravings, and designs.

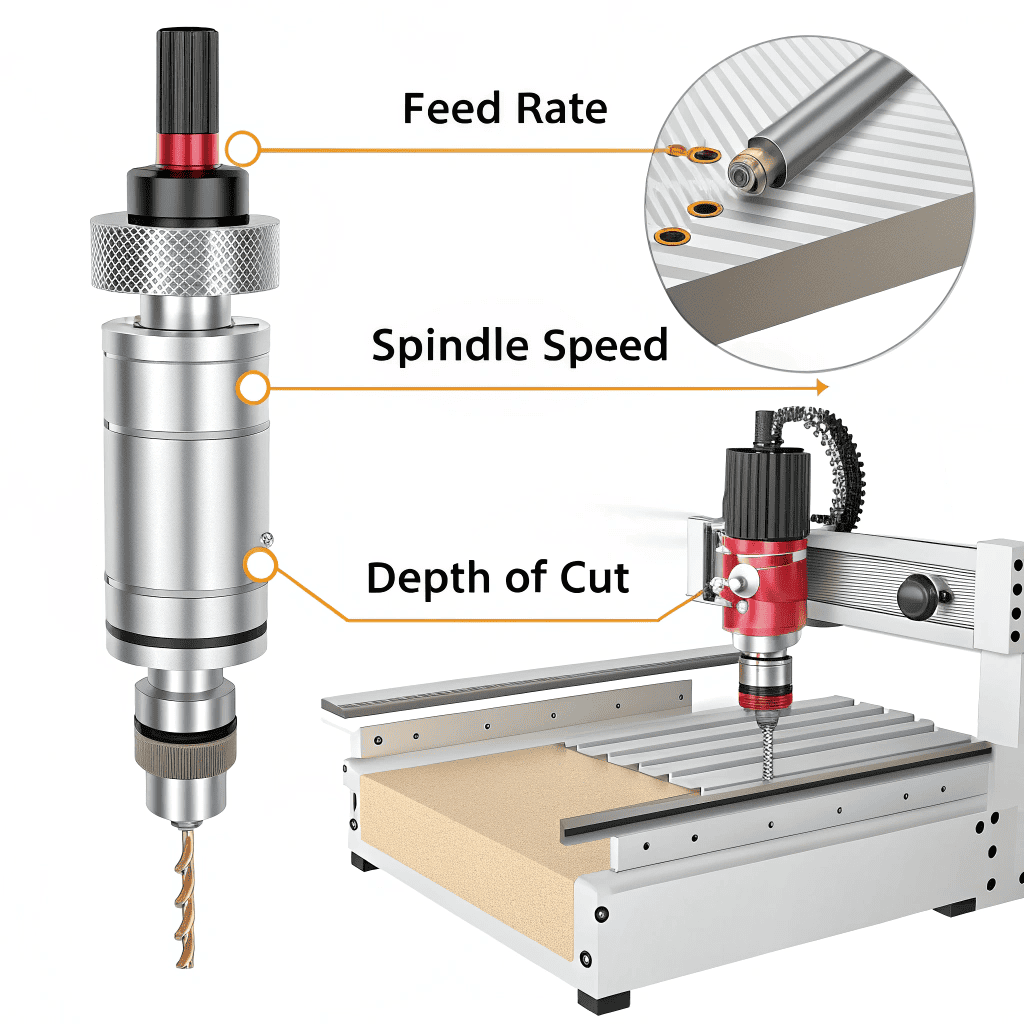

Feed rate, Spindle Speed, and Depth of Cut

Spindle speed, feed rate, and depth of cut are the major factors that influence the efficiency and quality of cutting .

1. Feed Rate

Feed rate refers to the quantity of material being cut by the tool. It is normally specified in units per minute (inches per minute or millimeters per minute). A good feed rate gives the tool enough but not enough that it will start to get overheated or too disproportionately worn out.

Example: F100 would be 100 units per minute feed rate.

A higher feed rate is appropriate for softer materials. While lower feed rates are appropriate for harder materials.

2. Spindle Speed:

Spindle speed means the speed with which the cutting tool rotates. It is also a critical parameter in controlling the cutting action. Because of the difference in spindle speeds materials need to offer optimum cutting performance.

Example: S1200 = Spindle speed 1200 RPM.

Heavy spindle speeds are generally employed for machining on comparatively soft material. It lowers spindle speeds for metal, as well as on very abrasive material. This is a precautionary measure not to wear down the tools or heat up.

3. Depth of Cut

The depth of cut is the volume of material removed by the tool in a single pass. It will typically be given per pass. It will have to change with material hardness and with the ability of the cutting tool.

Z-5 must have a depth of cut of 5 units (5 inches or 5 mm).

There is less depth of cut used in machined hard material or detail machining. More cuts can be utilized if more material removal needs to be achieved in less time.

Such environments are used in conjunction to realize optimal surface finish, cutting performance, and tool life. Switching between them as a function of product and material results ensures accuracy and optimal CNC routing.

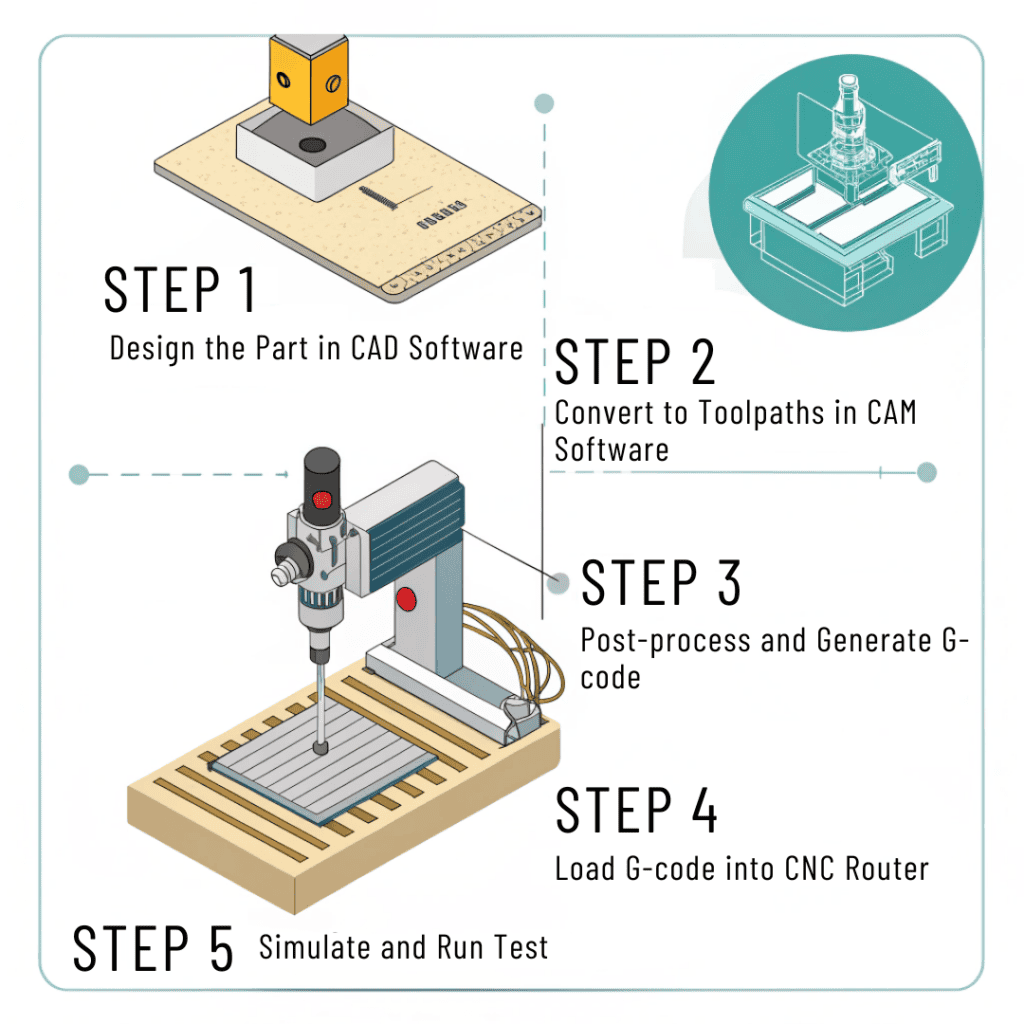

Step-by-Step: How to Program a CNC Router

CNC router programming is all about making parts, toolpaths, and machine instructions. Below is a simple step-by-step guide to start with.

Step 1: Design the Part in CAD Software

Begin by designing a 2D or 3D model of your project on CAD software such as Fusion 360, AutoCAD, or Easel. This model is the blueprint from which your CNC router will work.

Step 2: Convert to Toolpaths in CAM Software

Export your CAD design to CAM software such as VCarve or Fusion 360 CAM to manage cutting operations. Toolpaths will be created and exported in the form of G-code that can be run on your CNC router.

Step 3: Post-process and Generate G-code

Export your toolpaths to G-code for your CNC router using the CAM software post-processor. It includes instructions for all of the movements, speeds, and cutting depths.

Step 4: Load G-code into CNC Router

Input the created G-code into your CNC router via a G-code sender such as UGS or Mach3. This gets the machine ready to perform the instructed operations.

Step 5: Simulate and Run Test

Test the G-code in your control software to check whether there are any mistakes. If all is well, create a test on waste material for safety and accuracy purposes.

How to Use a CNC Router for Wood

How to use a CNC machine for wood? It is simple to cut to precision, engrave, and make thin details using a CNC router g code for wood. It is a profitable woodworking machine that can be used for anything.

Wood Material Prep

Begin by using a flat piece of wood to work with in your project – hardwood, plywood, and MDF are good choices. Clamp or vacuum table the wood to the CNC bed with a solid grip so that it will not shift because it will be being machined.

Tool Selection (end mills, V-bits, etc.)

Choose your cutting tool based on the material and type of cut. Edge cutting and depth of cut with end mills, and detail cut and engraving with V-bits. Curves and 3D models with ball nose bits.

Fixing the Workpiece

Hold the wood in place on the CNC router table so that it doesn’t move when cutting. Apply clamps, double-sided tape, vacuum tables, or screws based on the material size and depth of cut.

Best Practices for Clean Cuts

- Correct Tool: Use the right bit for wood and cut type. New, high-quality bits cut with less tear-out and improved finish.

- Ideal Speeds: Use the correct spindle speed and feed rate. It is based on wood species to avoid burning or poor cuts.

- Correct Depth of Cut: Cut shallowly instead of taking deep cuts to create smooth edges and reduce stress on the tool.

- Sharp Tools: Regularly check and replace dull tools. It is to avoid sloppy cuts and potential damage to the material.

- Clear the Work Area: Clear the bed of the CNC of dust and dirt and avoid tool inaccuracy and defects.

Common Mistakes to Avoid

Errors during operation on a CNC router can lead to costly errors and material wastage. Some of the common errors that need to be avoided for general operations and maximum results are as follows:

Programming Errors

Coding mistakes such as incorrect G-code or toolpath values will create improper cuts or machine crashes. Make sure that your program is in the correct coordinates, feed rates, and tool selection prior to running your program.

Wrong Tool or Spindle Speed

Incorrect cut quality, tool life, or even material damage can be caused by incorrect tool or spindle speed. Always hold the material straight with the tool. Utilize spindle speed as manufactured by the factory in an effort to achieve maximum performance.

Improper Workpiece Clamping

If the workpiece is not held in place, it will shift as it is being cut, and this will result in poor cuts or even destroy the CNC router. Ensure that the workpiece is firmly held in place using clamps, tape, or a vacuum table so that it will not shift while cutting.

Tips for Beginners

Initially, it can be quite difficult to master a CNC router, but if you are receiving the right method, then you can have good results. Here are a few steps so that you do not go in the wrong direction.

Start with Softwood

Begin with the pine or cedar, the softwoods which are thus best to practice upon. They will not dull the tools and lead to errors. A softwood provides a learning experience and gaining mastery of the machine response.

Use Simulation Software

Before you machine your actual material, simulate toolpaths and potential errors. In this manner, you will be able to identify errors in time. Thus will not be cheated in terms of precision and money, whereas doing it on actual machining.

Join CNC Communities and Forums

Join CNC forums and communities to learn from other experienced users, gain tips, and receive tips on how to troubleshoot. It is worth joining to learn more, resolve issues, and remain up to date with best practices.

Ending Lines

How to program a cnc router? In simple terms, to excel at CNC routing, you only need to learn a few concepts like G-code, tooling, and right workpiece clamping. You will produce correct and professional-quality pieces if you are well-prepared.

You may utilize that bit of caution while carrying out the process. Start with beginner cnc programming by undertaking simple tasks such as easy warm-ups and building confidence. If confident, go ahead and attempt to do hard designs to expand your skill set further.

For your skill upgrade, find a superior cnc wood router tutorial on CNC routing techniques, cnc router programming, and project design. Happy machining!

Do you require training on CNC routers? Wish to upgrade your CNC skills? Contact us to learn from professionals and acquire hands-on training to become a master of your CNC router.

Discover our CNC wood machining services. Discover how our precise CNC wood machining services can bring your projects to life. Learn more at HK Spare Parts.

Get our beginner cnc programming guide PDF: New to CNC routing? Download our free PDF beginner’s guide to CNC routers and start again!