Did you know that the global forging market is set to reach $145.44 billion by 2030? That’s because forged parts stay strong and work well across many industries. Forging, a method used for over 6,000 years, is still one of the most important ways to shape metals today.

Hanke Construction Machinery Manufacturing Co., Ltd., creates high-quality forged parts. You can use them in construction, mining, and transport. In this guide, you will learn what forging is, how it works, and why it is a smart way to make strong metal parts.

What Is Forging?

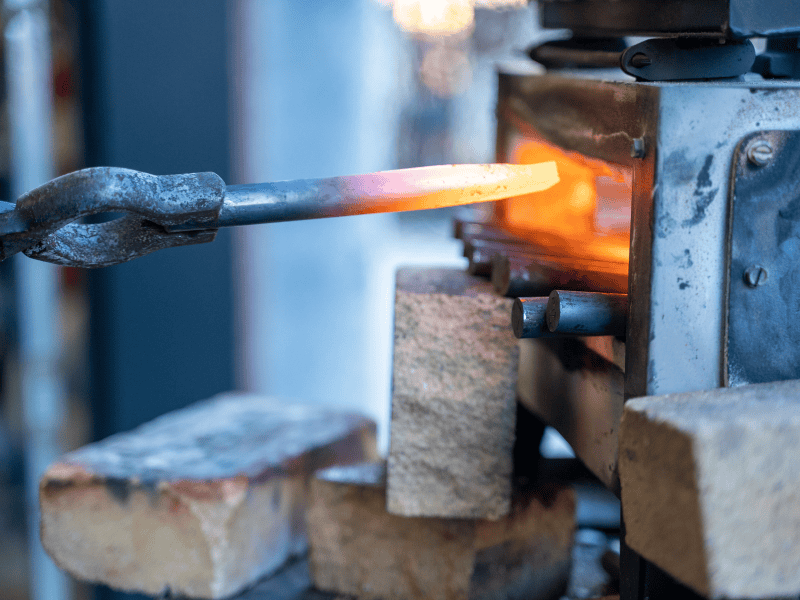

Forging is a metalworking process where metal is shaped by applying localized compressive forces. These forces are typically delivered using a hammer (often a power hammer) or a die. Forging processes are often categorized based on the temperature at which they occur: cold forging (a form of cold working), warm forging, and hot forging (a form of hot working). In warm and hot forging, the metal is usually heated in a forge before shaping. Forged components can vary greatly in size, from under a kilogram to several hundred metric tons.

Historically, forging has been practiced by smiths for thousands of years to produce items like kitchen tools, hardware, edged weapons, hand tools, cymbals, and jewellery. Most forged parts also undergo additional processing, such as machining, to achieve the final specifications. Today, forging remains a vital global industry.

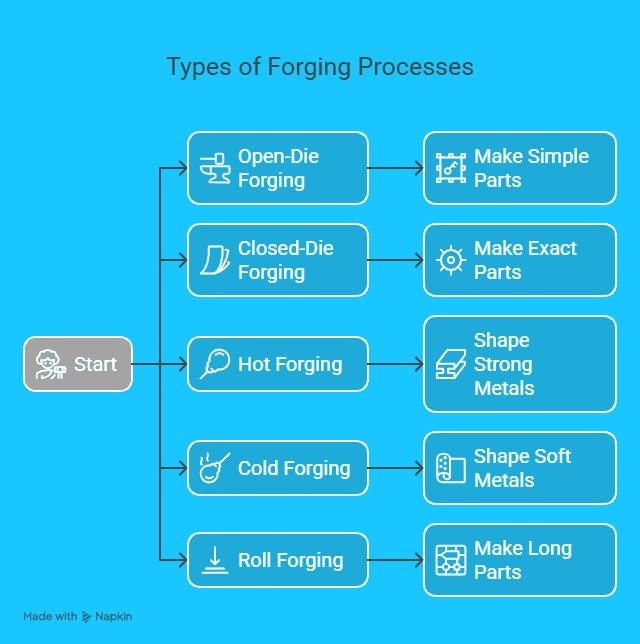

Types of Forging Processes

There are many ways to forge metal. The way workers choose depends on the shape they need and the type of metal they are using. Let’s look at some of the main types of forging.

Open-Die Forging

Open die forging is a process where a piece of metal is shaped between several dies that do not fully enclose it. The metal is shaped as the dies “hammer” or “stamp” it through a series of movements until the desired form is reached. Parts produced through open forging often require secondary machining and finishing to meet the required tolerances. Open die forging is commonly used for small-quantity production of simple shapes like discs, rings, sleeves, cylinders, and shafts.

Closed-Die Forging

Closed die forging, also called impression die forging, is a metal forming process where a piece of metal is compressed under high pressure to fill a closed die cavity. For certain complex shapes, a second forging operation may be needed to achieve the final dimensions and form. The cost of a closed die forged part can depend on factors such as the material used, the precision of tolerances, and whether heat treatment is required.

Hot Forging Process

In the hot forging process, workers heat the metal until it becomes soft but not liquid. This makes it easier to shape without breaking or cracking. Hot forging works well for strong metals like steel bars and alloy steels. Heating the metal helps it stay tough and keeps the grain flow strong inside the part.

Cold Forging

Cold forging happens when workers shape metal without heating it much. It is usually done at room temperature or a little warm. Cold forging is great for soft metals like copper and aluminum. It helps the parts stay strong, smooth, and maintains their dimensional stability. Cold-forged parts often need very little finishing work.

Roll Forging

In roll forging, workers pass the metal between two rollers. The rollers squeeze and stretch the metal into a long shape. This is a fast way to make parts like axles, rods, and levers. Roll forging also improves the grain flow inside the metal.

Forging Manufacturing Process

The forging process has a few simple steps. Each step helps turn a plain piece of metal into a strong part.

Step 1: Heating the Metal

First, heat the metal to make it easier to shape. In the hot forging process, the heated metal can get very hot, sometimes as hot as 2,000 degrees Fahrenheit! Workers forge soft metals with less heat by using warm forging or cold forging.

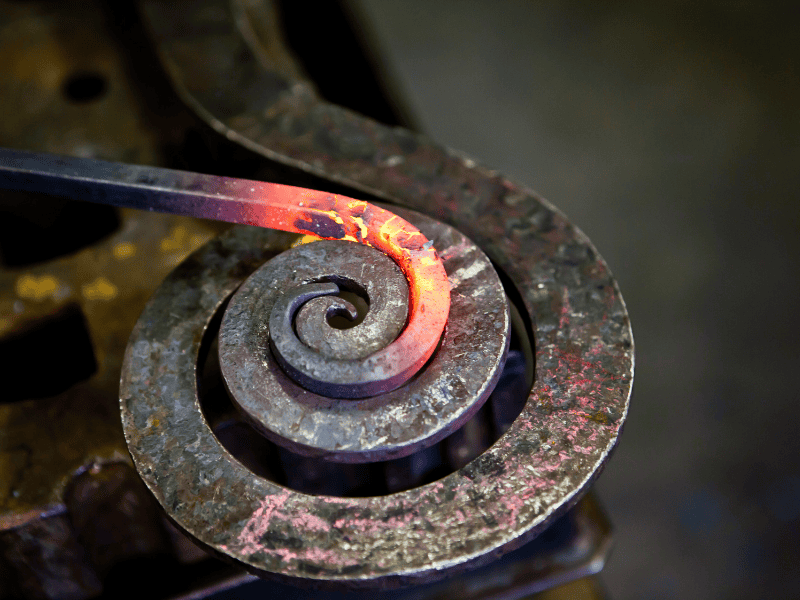

Step 2: Shaping the Metal

Workers place the ready metal on a stationary anvil or inside a die. Workers shape the metal with strong hammer strikes. They also use machines like hydraulic presses to apply continuous pressure. In drop-hammer forging, the hammer hits the metal very quickly. It shapes the metal in a few milliseconds.

This step changes the metal’s grain flow to match the new shape, making it stronger and tougher. Good forging avoids problems like internal voids and keeps the metal solid all the way through.

Step 3: Finishing the Part

After shaping, workers may trim extra metal or smooth rough edges. Some parts also get heat treatment to make them even stronger. Heat treatment helps the metal become tougher and better at handling heavy hits, pulling forces, and long use.

The forging process controls the shape very well. Many forged parts come out close to their final form and need very little extra work. This saves production costs and labor costs.

Forging is a smart way to make strong, reliable parts from different types of metal.

Applications of Forging in Industry

The forging industry plays a big role in making strong parts for many fields like cars, airplanes, and oil rigs. Forged parts are everywhere in today’s world because they are strong and dependable. Let’s look at some places where forging plays an important role.

Automotive Industry

Cars and trucks have many forged parts. Things like ball joints, gears, axles, and crankshafts are often forged. Forged parts offer fatigue resistance and impact resistance. They can handle bumps, heavy loads, and long drives without breaking. Thanks to forging, vehicles last longer and stay safer.

Aerospace Industry

Airplanes need parts that are strong but also light. Forged parts, made from alloy steels and stainless steel, are perfect for this job. Things like landing gear and engine parts are often forged to provide most strength without adding extra weight.

Oil, Gas, and Marine Industries

Oil rigs, pipelines, and ships work in tough places with saltwater and heavy pressure. Workers use forged parts because they are very strong and do not rust. These parts help the equipment stay safe and stop it from breaking.

Construction and Heavy Machinery

Big machines used in building and mining, like bulldozers and cranes, use forged parts too. Forged tools and parts give machines the toughness they need to handle heavy jobs every day.

Who Makes Strong Forged Parts?

Many industries like construction, mining, and oil drilling need strong metal parts. Hanke Construction makes forged parts that help these industries every day.

Here is what Hanke does:

- We make strong parts like shafts, sleeves, and shovel teeth.

- Our big factory has machines like laser cutters, CNC benders, and lathes.

- We check every part carefully to make sure it is strong and safe.

- Our parts are used in buildings, railways, mining sites, and oil fields.

- Big companies like XCMG Group trust our parts.

Advantages of Forging

Forging has many important benefits that make it a top choice for making strong metal parts.

Superior Strength

One of the biggest advantages is superior strength. Forging shapes the metal’s grain flow to follow the part’s form. This makes it stronger and helps it last longer under pressure. Forged parts also have better fatigue resistance, so they can handle lots of stress without cracking or breaking.

Better Mechanical Properties

Forged parts show better mechanical properties like tensile strength and impact resistance. They are tougher and more reliable than parts made by other methods like the casting process. This is why forging is used for critical jobs, such as airplane parts and car engines.

Cost and Material Savings

Forging helps save money, too. Because forged parts are close to their final shape, they need fewer secondary operations like trimming or machining. This saves time, lowers production costs, and reduces labor costs. Also, there is less excess metal wasted, leading to material savings.

Dimensional Accuracy and Reliability

Forged parts fit exactly where needed and have fewer weak spots. This makes them safer and more reliable for important jobs.

Common Questions (FAQ)

How does hot forging differ from cold forging?

Workers heat metal in hot forging until it becomes soft and easy to shape. They form strong parts faster, which is helpful for hard metals like steel. Cold forging shapes the metal at room temperature or a little warm. It works best with soft metals like aluminum and gives better, smoother surfaces. Cold forging also needs less finishing work later.

Why is forging stronger than casting?

In casting, workers melt metal and pour it into a mold. When the metal cools, tiny cracks or weak spots can happen. In forging, the metal stays solid while workers shape it. This keeps the inside of the metal strong and smooth. Forged parts stay strong and are less likely to break.

How is forging different from stamping or machining?

Stamping and machining cut and shape metal from sheets or blocks. These methods can create sharp edges but might disturb the metal’s inside structure. Forging, but, presses and squeezes the metal, keeping its strength. Forged parts also have better impact resistance and can handle critical stress better.

What metals are commonly used in forging?

Forging can shape many kinds of metals. Workers forge metals like carbon steel, stainless steel, alloy steel, tool steel, and soft metals like copper and aluminum. They choose the metal based on what the part needs to do and how strong it must be.

Conclusion

Forging makes metal parts strong, safe, and able to last a long time. Workers press and shape hot metal to make it tougher and to save money on making and fixing parts.

You can find forged parts in cars, airplanes, oil rigs, and big machines. Forged parts are stronger, fit better, and handle hard hits better than other kinds.

If you need strong and trusted parts, forging is the smart choice. Hanke Construction Machinery Manufacturing Co., Ltd. can make high-quality forged parts for you. Contact us today to get started!