What makes alloy steel different from carbon steel? Alloy steel consists of a mixture of iron with elements like chromium, nickel, or molybdenum. These extra elements make the steel stronger, harder, and more resistant to rust and heat. Some alloy steels can have up to 50% of these added metals.

In this guide, you’ll learn how alloy steel works, how it compares to carbon steel, and where it’s used. This information is helpful for students, engineers, and anyone working with metal.

What Is Alloy Steel?

Alloy steel is a type of steel made by mixing carbon steel with one or more alloying elements. These added elements can change how the steel behaves, making it stronger, tougher, or more resistant to wear, heat, or corrosion. If you work with materials that need to perform under pressure, you’ve likely come across alloy steel.

Common alloying elements include:

- Manganese: When mixed with a little sulfur and phosphorus, manganese makes steel less likely to break and easier to shape with tools.

- Chromium: A small amount (about 0.5% to 2%) makes the steel harder. More chromium (up to 18%) helps protect it from rust.

- Vanadium: Just a tiny bit (about 0.15%) makes steel stronger, better at handling heat, and gives it a better grain pattern. When used with chromium, the steel gets tougher but can still be shaped.

- Nickel: Nickel makes steel stronger when used up to 5%. If you add more than 12%, it helps stop the steel from rusting.

- Tungsten: Tungsten helps steel handle high heat and gives it a stronger structure. It also makes the melting point higher.

Each element gives the steel a new quality. For example, chromium helps make stainless steel. Stainless steel does not rust easily. Molybdenum helps the steel stay strong in high heat.

There are two types of alloy steel:

- Low-alloy steel – has a small amount of added elements (less than 5%)

- High-alloy steel – has more added elements (more than 5%)

Alloy steel is useful because it can be used for many jobs. It is used in cars, buildings, tools, and machines. It can be made to resist rust, stay strong in heat, or last a long time.

Alloy Steel vs Carbon Steel: Key Differences

Alloy steel and carbon steel may look the same, but they are very different inside. These two types of steel are used in different ways. To choose the right one, it helps to know how they are not the same.

Chemical Composition

- Carbon steel is made with iron and carbon. It has little or no other elements.

- Alloy steel is also made with iron and carbon, but it has extra elements like chromium, nickel, or molybdenum.

These added elements change how the steel behaves. For example, they can help the steel stay strong in heat or stop it from rusting.

Mechanical Properties

- Strength: Alloy steel is usually stronger than carbon steel.

- Hardness: Alloy steel can be harder, which helps it last longer.

- Ductility (how much it can bend): Carbon steel is easier to shape.

- Toughness: Alloy steel often handles stress better, especially in tough places.

Cost and Availability

- Carbon steel is cheaper and easy to find. It is used in many basic jobs.

- Alloy steel costs more because of the added elements. It is used when special strength or features are needed.

Typical Applications

| Feature | Carbon Steel | Alloy Steel |

| Used in | Pipes, construction, tools | Aircraft, cars, pipelines, heavy machines |

| Cost | Lower | Higher |

| Rust resistance | Low | Can be high (with chromium or nickel) |

| Strength | Moderate | High (can handle heat, pressure, wear) |

| Ease of shaping | Easier | May need special tools |

What Is Alloy Steel Used For?

Alloy steel is used in many industries where regular steel just isn’t strong or reliable enough. If your work involves machines, heavy loads, or high temperatures, there’s a good chance alloy steel plays a role.

Let’s look at some common uses.

Automotive Components

Car parts like gears, axles, crankshafts, and drive shafts are often made from alloy steel. These parts need to handle a lot of stress, especially when the vehicle is moving fast or carrying heavy weight. Alloy steel helps them last longer and stay strong.

Oil & Gas Pipelines

Pipelines carry oil and gas over long distances, often underground or underwater. These pipes must be tough and resist rust, pressure, and heat. Alloy steel is a smart choice here because it doesn’t wear out easily.

Construction Materials

In buildings, bridges, and heavy equipment, you need materials that are strong but not too brittle. Alloy steel beams, rods, and supports are often used to keep structures safe and solid.

Aerospace Parts

Aeroplanes face high speeds, big temperature changes, and strong forces. That’s why landing gear, engine parts, and fasteners are often made from special alloy steels that can take the pressure.

Tooling and Machinery

Tools and machine parts that cut, press, or shape other materials go through a lot. Alloy steel is great for tool bits, dies, and heavy-duty machine parts because it stays strong and sharp under stress.

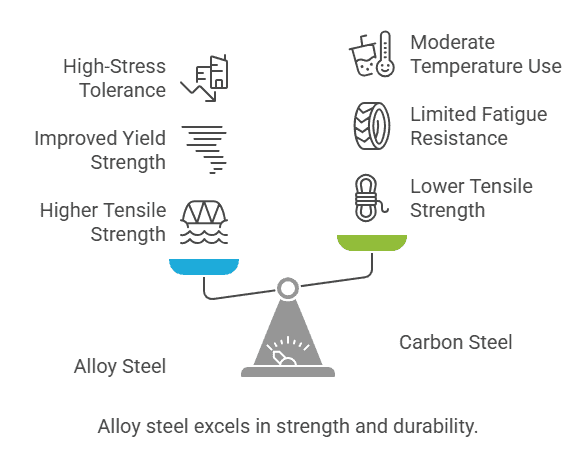

Which Is Stronger: Alloy Steel or Carbon Steel?

If you’re choosing steel for a project, strength is probably one of your top concerns. So which one is stronger—alloy steel or carbon steel? Let’s compare them based on key strength factors.

Tensile Strength

Tensile strength means how much pulling force a material can handle before breaking. Alloy steel usually has higher tensile strength than carbon steel because of the added elements like nickel or molybdenum.

So, if your part needs to resist stretching or pulling, alloy steel is often the better choice.

Yield Strength and Fatigue Resistance

Yield strength is how much force a material can take before it starts to bend. Fatigue resistance tells you how long the metal can last under repeated use.

Alloy steels are often heat-treated to improve both of these properties. That makes them more reliable for moving parts or tools that face constant use and stress.

Carbon steel does okay in many applications, but it usually can’t take as much wear and tear over time.

High-Stress and High-Temperature Use

Alloy steels are also better in hot environments or where there’s a lot of pressure. That’s why they’re used in aerospace, oil rigs, and power plants.

When Should You Choose Each One?

| Need | Choose This Steel |

| Lower cost | Carbon Steel |

| High strength | Alloy Steel |

| Rust and heat resistance | Alloy Steel |

| Easy cutting and shaping | Carbon Steel |

| Heavy-duty performance | Alloy Steel |

Treatment of Carbon and Low-Alloy Steels

To make steel stronger, tougher, or easier to work with, it often goes through heat treatment. This is a way to heat and cool steel to change how it behaves. Both carbon steel and alloy steel can be heat treated.

Heat Treatment Basics

There are three main heat treatment steps:

- Annealing: The steel is heated and cooled slowly. This makes it softer and easier to shape or cut.

- Quenching: The steel is heated and then cooled quickly in water or oil. This makes it harder but also more brittle.

- Tempering: After quenching, the steel is heated again but at a lower temperature. This removes brittleness and makes it tougher.

Alt text:

“Diagram showing three steel heat treatments: annealing makes steel softer, quenching increases hardness but causes brittleness, and tempering improves toughness.”

How Alloying Elements Affect Treatment

Alloying elements like chromium, manganese, and molybdenum change how steel reacts to heat. For example:

- Chromium helps the steel stay hard after quenching.

- Molybdenum makes the steel strong at high heat.

- Manganese helps the steel absorb shock without cracking.

This means alloy steel can be treated in more ways than plain carbon steel. It can be made harder, tougher, or more heat-resistant—depending on what you need.

Microstructure Changes

Heat treatment changes the steel’s microstructure—the tiny grain shapes inside the metal. These changes affect:

- Hardness

- Flexibility

- Strength

A finer microstructure usually means stronger, longer-lasting steel.

Real-World Examples

- In automotive parts like gears or crankshafts, quenching and tempering give the right mix of strength and toughness.

- In oil and gas, alloy steel pipes are treated to resist heat and pressure deep underground.

- Construction tools are hardened to stay sharp and last longer.

How Huasuma Helps with Alloy Steel Parts

Huasuma is a company that makes strong metal parts using alloy steel. These parts are used in cars, machines, and buildings because they can handle heat, pressure, and heavy use.

Here’s what Huasuma does:

- Makes strong parts like gears, shafts, and tools from alloy steel

- Uses big machines to shape and cut metal exactly how you need

- Checks every part carefully to make sure it is safe and strong

- Uses special heat treatments so the parts last longer and work better

- Works with many industries like automotive, construction, and oil & gas

Conclusion: Choosing the Right Steel for the Job

Now you know how alloy steel and carbon steel differ in makeup, strength, cost, and uses. If you need extra toughness, high heat resistance, or better wear performance, alloy steel is your go-to. For simpler, budget-friendly projects that don’t face extreme stress, carbon steel will usually do the job.

When you pick steel, think about:

- Performance needs: Will the part face high loads, heat, or wear?

- Budget: How much can you spend on material?

- Availability: Which steel type can you get quickly?

Need help finding the right steel for your next project?

Reach out to Huasuma to explore alloy steel options made to handle real-world stress and performance needs.

Frequently Asked Questions

What is the main difference between carbon steel and alloy steel?

Carbon steel has only iron and carbon. Alloy steel includes other elements like chromium or nickel to boost strength and resistance.

Is alloy steel rust-resistant?

Some alloy steels resist rust better—especially those with chromium. But you may still need coatings or treatments for full protection.

Can alloy steel be welded easily?

Many alloy steels weld well, but some (with high alloy content) need special procedures to avoid cracking.

What are examples of low-alloy steels?

Common low-alloy steels include 4140 (chromium-molybdenum) and 4340 (nickel-chromium-molybdenum), used in shafts and gears.