A CNC machine is a computerized controlled program that runs a machine. CNC meaning Computer Numerical Control. It is a unique type of machinery. It is used to manufacture components from various materials. CNC is a quibble for computerized control.

That means a computer operates the CNC machine. It is not human-operated. All of that requires a human-created program with special codes. The program tells the machine exactly what to do. It includes where to move, at what speed, and how deep to cut.

CNC machines are highly accurate. They are producing the same piece repeatedly without error. They are used in numerous industries, including automotive, aerospace, and furniture design. These machines speed up work to make it easier and faster.

At the same time, they include lathes, milling machines, and laser cutters. They can become expensive. They are valuable tools for manufacturing strong, complex components. Learning to use one of these machines is a skill used in many modern-day jobs.

What Does CNC Stand For

CNC machine stands for machine using computer numerical control. It suggests that it has computers that control the movements of machines. Some are like cutters, drills, or lathes. The computer sends instructions in the form of numbers and codes to perform the action.

These commands direct the machine exactly how to move, which speed to use, and how deeply to cut. It makes the work more accurate and speedier. The factory has large CNC machines. These produce components for cars, planes, and machines.

CNC Meaning Explained

CNC meaning is controlling machines via a computer. The computer helps the machine work with treats. They are called codes that make the program run. The machine does exactly what it’s told to do.

A CNC machine can cut, drill, or form metal, wood, or plastic materials. It is a high-speed and high-accuracy working apparatus. This means the components it produces are always flawless. They are uniform with every assembly.

This is important because CNC machines are employed in dozens of industries. This ranges from automotive to furniture manufacturing to electronics.

Much of the work is controlled by computers, resulting in fewer lapses. Other designs allow the CNC machine to run for several hours uninterrupted. It saves time and money.

History and Evolution of CNC Technology

CNC work began in the 1940s and 1950s. People were trying to find better ways to create machine parts. So John T. Parsons and his crew wrote out how the numbers could swivel machines. This helped to drive part accuracy, especially for airplanes.

In the 1950s, the first CNC machine was created. The machine operated using punched paper tape. The tape gradually gave way to better technology, such as computers. Computers shrank in size and cost in the 1970s. It continued into the 1980s, making CNC machines more commonplace in factories.

Today, CNC machines are making their way across the world. They help make cars, planes, tools, and many other things. Technology is improving. It is faster, better, smarter, and new tech comes out all the time. The CNC was invented to change how factories work and enhance product quality.

Why CNC Matters in Modern Manufacturing

CNC is a powerful tool in modern manufacturing. It is manufacturing products quickly, accurately, and with minimal waste. A computer controls the machine. Thus it can repeat the same work repeatedly. It is providing constant results. This is useful for creating large quantities of identical items, such as car parts or phone cases.

CNC machines can also operate for hours without stopping. It is reducing factories’ costs in terms of time and money. They are also very precise, meaning they work together well and function properly. CNC machines can also create very complex shapes. Something that would be difficult to accomplish manually.

Another reason CNC is important is safety. Computers control machines, so workers don’t need to be near dangerous sharp objects. CNC machines simplify manufacturing. Thus making it quicker, safer, and more efficient.

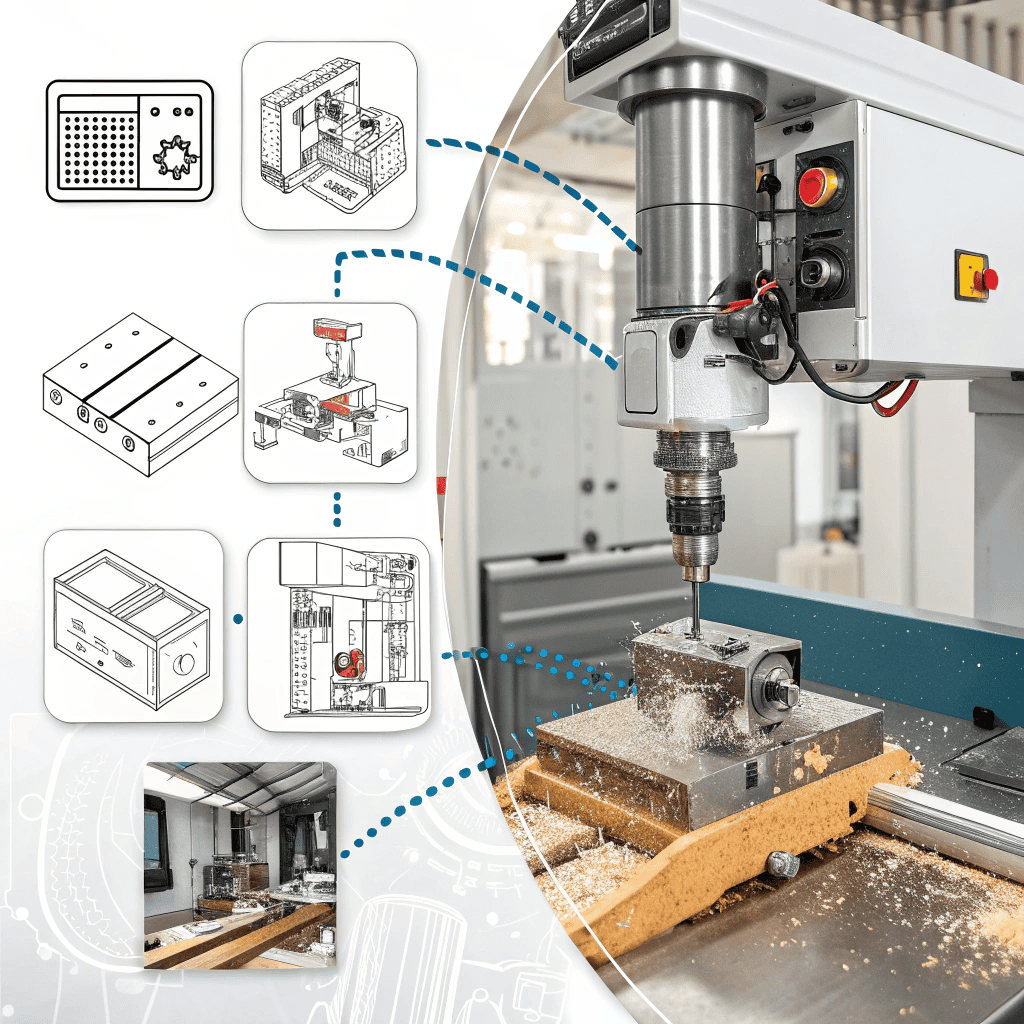

How CNC Machines Work

CNC machines operate by getting data from a computer. That controls tools such as cutters, drills, or lathes. The design has to be created on a computer by a person through special software.

Then, this design is converted to a program with some codes known as G-code. These codes tell the machine exactly the instructions. This includes what to do, where to move, how fast to move, and how deep to cut.

Once prepared, the program is uploaded to the CNC machine. This machine executes the instructions. It uses tools correctly to cut or shape material, such as metal, plastic, or wood. Then, the machine takes many steps and does not require help.

CNC machines also use sensors to monitor whether everything is working correctly. It can stop if something is wrong. The work is very accurate and very fast because a computer does everything. CNC machines are designed to create durable and precise parts.

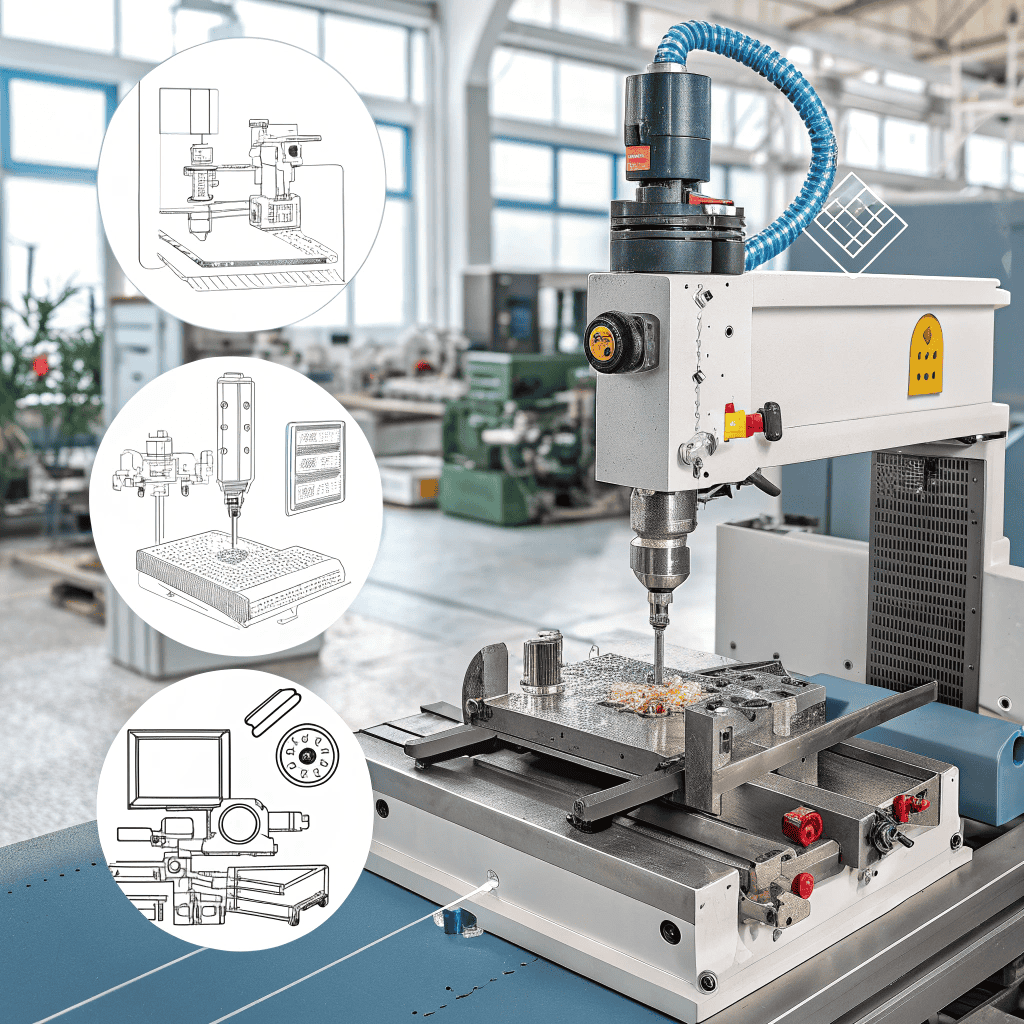

Basic Principles of CNC Machining

CNC machining makes it easy to understand the basic principles. CNC meaning Computer Numerical Control: a computer controls the machine’s actions. Here are the main ideas:

Part design: The first step is to design a part using a computer and special software (CAD, for example). This is how the final product looks like.

Developing the program: Design is transformed into a sequence of instructions. This is done using code, primarily G-code. This code instructs the machine what to do at each step.

Preparing the Machine: An appropriate tool (e.g., cutter, drill) is mounted to the machine. While the material (e.g., metal, plastic) is appropriately positioned.

Running the Program: This machine reads the code and moves the tool to cut or shape the material. It loops along the same path as in the program.

Building the Part: A machine completes the part quickly and accurately. Thus producing a result that closely mirrors the design.

Software and Programming (G-code, CAM)

Software and codes enable CNC machines to function. This consists of two parts: G-code and CAM Software.

G-code is a language that tells the CNC to perform specific tutorials. It tells the machine where to go, how fast to go, and what actions to take, such as cutting or drilling. G-code lines each provide a small instruction/step for the machine. This is very detailed and helps a machine perform the job accurately.

CAM software is a specialized class of software used for manufacturing automation. This software assists with converting the design into G-code. It begins when a designer creates the part using CAD.

Next, the CAM software converts that design into G-code. That is suitable for the CNC machine to interpret. CAM software simplifies the process by writing the program for the machine. While G-code includes the instructions. Thus a CNC machine is supposed to follow to manufacture a part.

Automation and Precision Benefits

The automated use of CNC machine machining tools offers precision. It is one major reason so many factories use them today.

Automatic refers to the machine’s ability to work itself. Once the program is set up, the machine completes the steps without someone overseeing it. This saves time. It enables workers to perform other important tasks while the machine continues.

Precision is the act or fact of being correct or exact. CNC machines are highly accurate. They are capable of cutting or shaping various materials. So, every part you make, whether 100 units or 1,000, will be exact. This is important when these parts fit together tightly. Parts are like car’s parts or machinery.

Automation and precision, together, allow factories to operate faster. Also, more accurately and at a higher quality. It also saves costs. It provides better outcomes for companies and consumers.

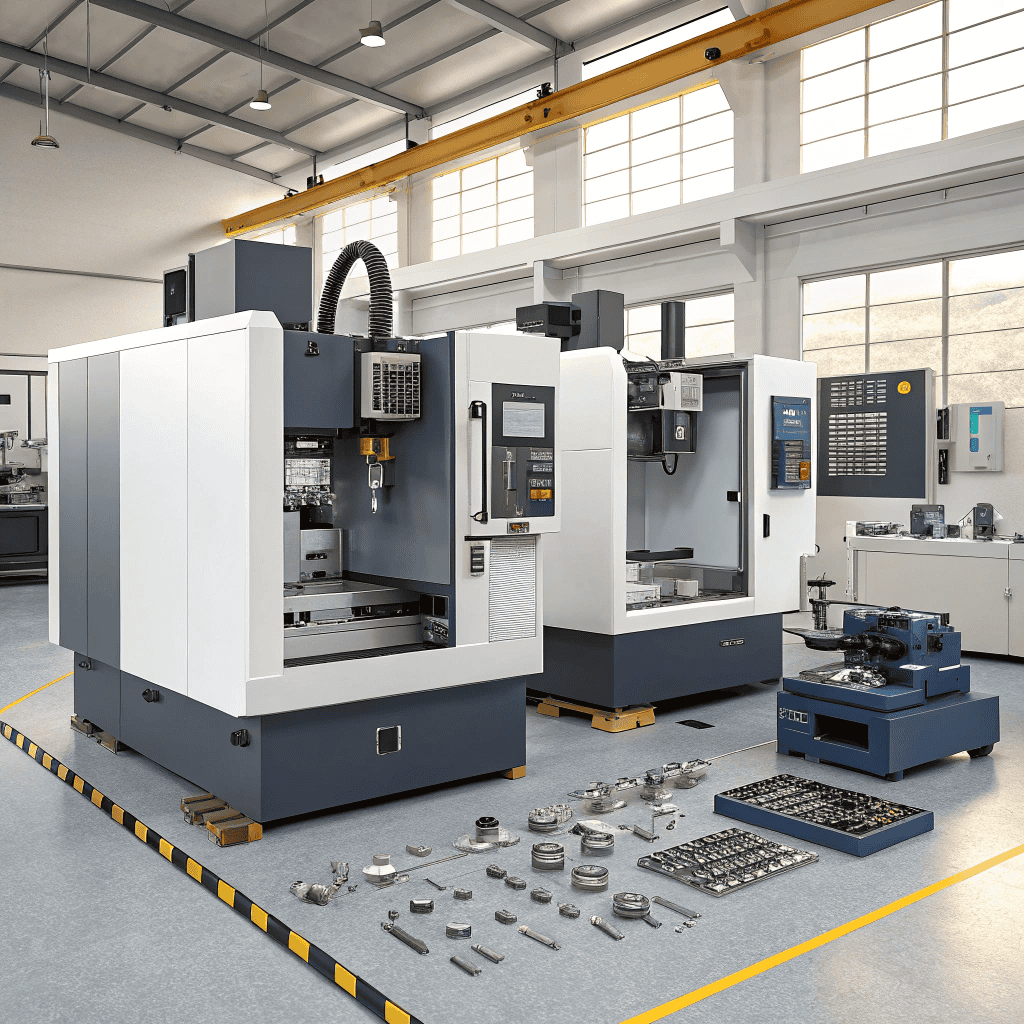

Types of CNC Machines

Although the CNC Machine types are different, each has a specific job. So here are a few common types of CNC machines explained:

CNC Milling Machine: CNC mills are capable of running on programs. These consist of number and letter-based prompts that guide pieces across various distances. The programming is employed for a mill machine. It could be based on either G-code or some unique language developed by a manufacturing team.

Basic mills consist of a three-axis system (X, Y, and Z). Though most newer mills can accommodate three additional axes.

CNC Lathe: In lathe machines, pieces are cut in a circular direction with indexable tools. The cuts are employed with precision and high velocity. CNC lathes are used to produce complex designs. It wouldn’t be possible to manually run versions of the machine.

Overall, the control functions of CNC-run mills and lathes are similar. As with CNC mills, lathes can be directed by G-code or unique proprietary code. However, most CNC lathes consist of two axes – X and Z.

CNC Laser Cutter: It uses a laser beam to cut or engrave metals, wood, or even plastic accurately.

CNC Plasma Cutter: In a plasma cutter, a plasma torch cuts the material. The process is foremost applied to metal materials. But can also be employed on other surfaces. Plasma is generated through a combination of compressed-air gas and electrical arcs. It is done to produce the speed and heat necessary to cut metal.

CNC EDM: Alternately referred to as die sinking and spark machining. It is a process that molds workpieces into particular shapes with electrical sparks. Current discharges occur between two electrodes. This removes sections of a given workpiece.

When the space between the electrodes becomes smaller, the electric field becomes more intense. Thus, it is stronger than the dielectric.This makes it possible for a current to pass between the two electrodes. Consequently, portions of a workpiece are removed by each electrode.

CNC Milling Machines

A CNC milling machine cuts and shapes different materials. This process uses a rotary cutting tool to remove small pieces from a solid block of material. The machine is controlled by a PC, which runs a program that tells the tool where to go.

CNC milling machines can generate holes, slots, and other contours. It is precise and can produce the same piece repeatedly without defects. These types of machines are used in many industries. Some are automotive manufacturing, metalwork, and product fabrication.

Everything is run by the computer. Thus, the work is better and faster. It is an indispensable tool of modern factories and shops.

CNC Lathes

CNC lathes are machines that can rotate a workpiece. It is done by contact with a computer-controlled tool. The machine can give it form, typically round or cylindrical. CNC lathes are speedy, precise, and used for producing items such as screws, rods, and rings.

What is a CNC Lathe?

A CNC lathe is a machining tool. It is used to manufacture or create round or cylindrical parts. It works by spinning the workpiece with an attached cutting tool. The cutting tool skims the material gently to abrade away extra bits that are not required. The computer determines how the tool moves and how fast the material spins.

CNC lathes are ideal for creating pipe, bolt, and ring types. They are also fast and precise. They can repeatedly reproduce the same shapes without bugs. A program, written in special code, is installed on the machine to tell it what to do.

CNC lathes are used in automotive components, machine tooling, furniture, and many other industries. They take about the same time and can yield sound, smooth, and well-formed components.

Applications of CNC Lathes

CNC lathes are used to manufacture round or curved parts in different industries. They are common in:

- Automobile sector: to manufacture shafts, gears, and engine parts.

- Aerospace: for creating durable, precise components for airplanes.

- Furniture making: to carve wooden legs, handles and knobs.

- Metalworking: for cutting and shaping metal rods and pipes.

- Electronics: to manufacture tiny, intricate components of devices.

CNC Lathe vs. Manual Lathe

- A CNC lathe is computer-controlled, and a manual lathe is hand-operated.

- A CNC lathe does the work according to a program. It is faster, more accurate, and can make the same part without making a mistake.

- A manual lathe requires a human to position the tools and operate the machine. It is slower and requires more technique, and there is a greater risk of human error.

- Manual lathes are suitable for simple or one-time jobs. Whereas CNC lathes are better for mass production.

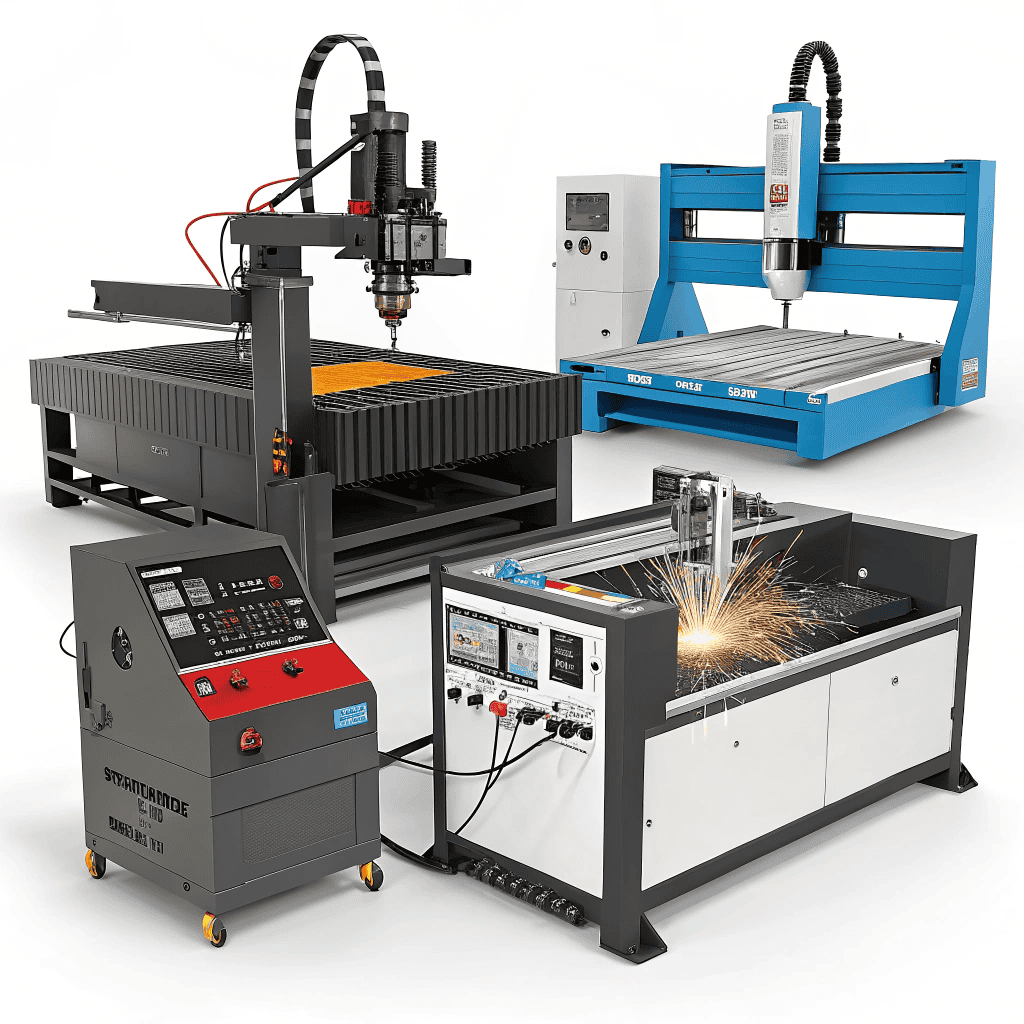

CNC Routers, Plasma Cutters, EDM, and More

These machines enable industries to function quicker, safer, and more accurately. Each is used in a specific way. It depends on the job type. Here is a short and straightforward explanation of a few other typical CNC machines:

CNC routers: They cut and shape wood, plastic, and softer materials. They are used in furniture, signs, and decorations. They function like milling machines but are ideal for lighter duty.

CNC Plasma Cutter: This type of machine uses a hot plasma torch. That can penetrate much deeper into metal. It can cut through three-inch-thick steel plates in seconds. It is used in many places, such as metal work, car repair, and industrial cutting jobs.

CNC EDM: Electrical Discharge Machine removes material using electric sparks. It’s used to make hard and detailed metal parts, such as tools and molds.

CNC Laser Cutter: Employs a powerful laser beam to cut or engrave materials. Materials such as metal, wood, or plastic with extreme accuracy.

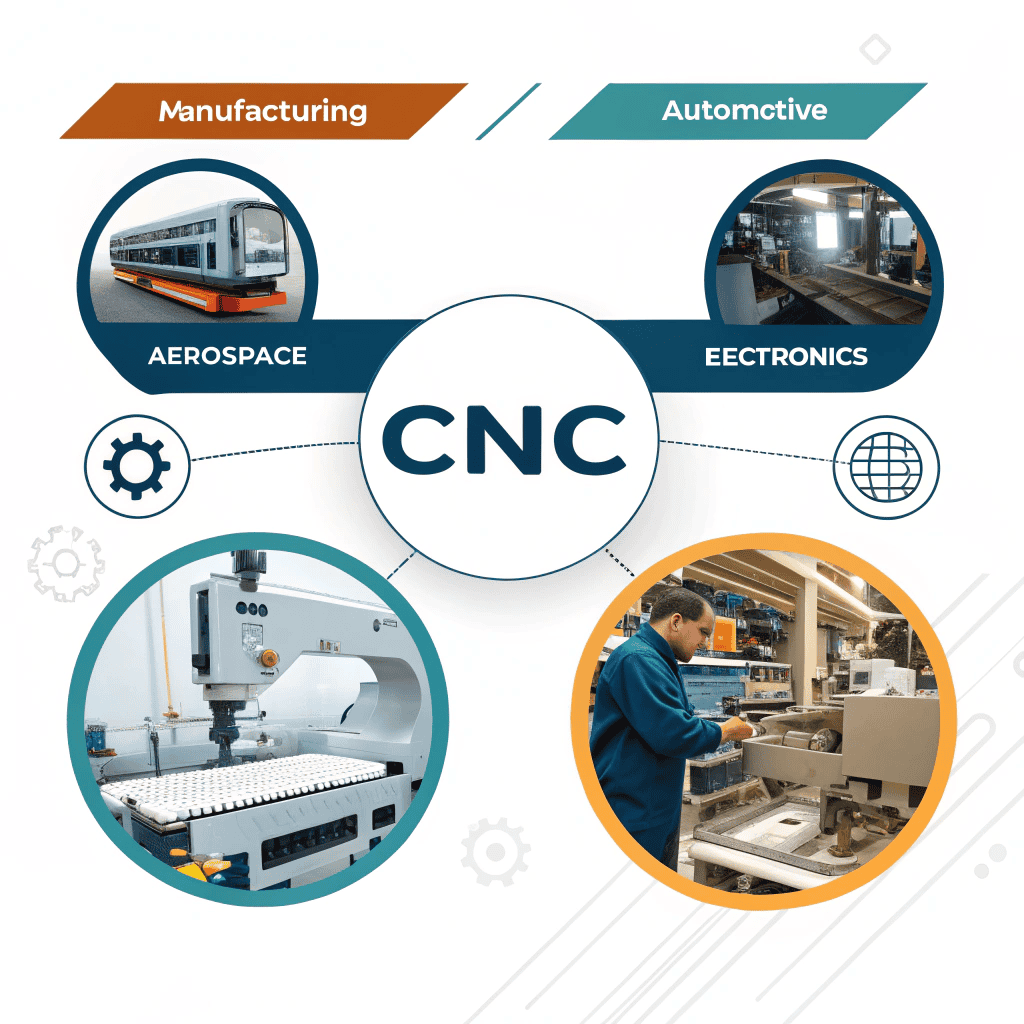

CNC Machinery in Industrial Applications

Numerous industries utilize CNC machinery to produce parts faster and more precisely.

CNC machinery makes engine parts, gears, and body parts in the automobile industry. In aerospace, they are deployed to design robust and lightweight airplane components.

Electronics companies use CNC machines to produce small and intricate components for devices. CNC routers carve wood into beautiful shapes in the furniture industry.

CNC machinery assists production companies in manufacturing high-grade products. It lessens the time spent and reduces mistakes. It is an essential device for modern industrial work.

Common Industries Using CNC Machines

CNC machines are used in various industries to provide both speed and accuracy. Some of the established fields are as follows:

- Automobile Sector: for manufacturing automobile components, such as motors, gear systems, and wheels.

- Aerospace Industry: Used for making aircraft parts that need strong and lightweight media.

- Electronics Industry: for small and detailed phone, computer, and gadget components.

- Wood for Furniture Sector: for tables, chairs, cupboards, etc.

- Medical Industry: for accurate tools, implants, and equipment.

Examples of CNC Machined Products

CNC machines create these products. It is ensuring high precision, a smooth finish, and the same shape each time. CNC machines help produce many valuable products in daily life and industry. Some simple examples include:

- Car engine parts like pistons, shafts, and gears.

- All perfectly shaped mobile phone cases.

- Furniture elements, such as wooden table legs or cabinet doors.

- Medical devices, including surgical tools and implants.

- Metal parts like bolts, nuts, and machine parts.

- Semi-permanent signs are made from wood, plastic, or metal.

How CNC Machinery Improves Productivity

CNC machinery helps in eliminating a lot of human error and speeds up the work. Thus increasing productivity in general. It is controlled through a computer,. It means it can operate for extended periods without a break.

It results in minimized time allotment. Thus, the possibility of manufacturing more components in reduced periods. Every time, the part is made the same with no variation, meaning that every part is identical.

Running these machines requires fewer workers, which lowers labor costs. The CNC machine works and allows workers to perform other tasks while it operates.

CNC machinery enables factories to produce more items at a faster rate. Also, more efficiently, and with a more excellent quality range.

Choosing the Right CNC Machine

- First, consider the material you’ll work with, such as metal, wood , or plastic. A CNC router is a suitable option for wood. For metal, you may also require a CNC milling machine or lathe.

- Consider the shape and size of the parts you want to create. Some are better suited for small and detailed work, whereas some are made for large or heavy parts.

- Also, check the speed, precision, and cost of the machine. Ensure it is within your budget and work requirements.

- Finally, select an easy-to-use and well-supported machine. This will enable you to get a quick start and get the job done efficiently.

Factors to Consider (Material, Complexity, Volume)

There are a few important things to think about when choosing a CNC machine. These help you pick the right one. It will give better results and waste less.

Subject and Material: Each material needs a different kind of CNC machine.

Complexity: If the part is simple, a basic machine is enough. If the part is hard to make, you need a better CNC machine.

Quantity: If you need to make many parts, you need a fast machine that can work for many hours.

CNC Machine Costs and ROI

CNC machines cost a lot when you first buy them. But they help save money later. The price depends on the type of machine. Small machines cost less. Big machines and fancy machines cost more.

ROI means the money you save or earn after buying a machine. CNC machines give more ROI because they work fast, make fewer mistakes, and need fewer people.

Companies can make more things and earn more money over time. Even though they cost a lot at first, CNC machines are worth it because they are fast, make good quality parts, and help make more money.

Maintenance and Upkeep

CNC machines need regular care to work well for a long time. You should clean them every day to get rid of dust, metal pieces, or oil. Oil helps parts move smoothly. You also need to check the tools and parts often to make sure nothing is broken.

Sometimes you need to update the software or fix small things. This helps the machine keep working well. Making a schedule for checking and cleaning the machine helps stop big problems. Taking care of the machine saves money, stops delays, and keeps the machine working like new.

Ending Lines

CNC machines are very important in making things. Computers control the tools. This helps the work go faster, easier, and with better results. CNC machines help make good parts from metal or wood. They are used in cars, planes, electronics, and even furniture.

- CNC is a smart and strong technology. It helps factories work faster and better.

- CNC stands for Computer Numerical Control.

- This software uses special programs and codes like G-code.

- CNC machines make fewer mistakes, save time, and are safer.

- Some examples of CNC machines are milling machines, lathes, routers, and plasma cutters.

- These machines are used to make many things like engine parts, phone covers, and furniture.

- The machine you choose depends on what material you use, how hard the part is to make, and how many you need.

- CNC machines cost a lot at first. But they give good value and help make more things over time.

- If you take care of the machine, it will work well for many years.

Are you ready to improve your production?

Hanke Construction Machinery Manufacturing Co., Ltd. is a top CNC machining company. Contact us to get the best and most trusted CNC machining services.

We make precision parts, custom designs, and large orders with expert results. You can also add our visuals to your B2B features.

Frequently Asked Questions

What does CNC stand for in machining?

CNC means Computer Numerical Control. A computer controls how the machine and tools move. The machine replaces hand work. It follows a program to cut, shape, or drill metal, wood, or plastic. This makes parts faster and more correct.

What is the difference between CNC and manual machines?

CNC machines use a computer and program to run the tool. They work by themselves. They can make the same part again and again with high accuracy. In manual machines, a person moves the tools. This is slower and may have small mistakes.

CNC machines are faster, more accurate, and good for making many parts. Manual machines are better for simple or one-time jobs.

How accurate are CNC machines?

CNC machines are very exact. They can cut and shape materials with tiny, careful moves, as small as 0.001 mm!

CNC machines can make the same part again and again without mistakes. This is because they use computer programs. This is very important in cars, planes, and electronics where parts must fit perfectly.

With good setup and care, CNC machines give the same great results every time.

Are CNC machines expensive?

Yes, CNC machines cost a lot, especially the big and complex ones. The price changes by type, size, and features.

Smaller machines cost less. But high-tech ones for metal or large parts are more costly.

Even though they cost a lot at the beginning, CNC machines save money later. They work faster, make fewer mistakes, and need fewer people. So, many businesses think they are a smart buy.