Understanding the Best Forging Methods: Processes and Applications

We see metal everywhere, in cars, buildings, tools, and machines. But have you ever thought about how those strong metal parts are made? One common way is forging. It is an old method that is still used today because it makes metal parts really strong and long lasting.

Big metal objects like Car parts, airplane engines, and big construction equipment are often made up from forging. But there is more than one way to do the forging process, and with this variety choosing the right method is not always easy. Each forging methods has pros and cons, and picking the right one can really affect how well your project turns out.

Here we will cover what forging is, important words to know, and the different ways to do it. We will also talk about the tools used and why temperature matters so much in getting the final product just right. Whether you are new to forging or want a clearer understanding, this guide will explain it simply.

Understand Forging

Forging is a method to shape metal by heating it up and pressing or hammering it into the required form. The goal is to make parts that are super strong and last longer than those made by other methods. Why? Because forging makes the metal’s internal structure tighter and more organized, which boosts its strength and durability. At Hanke Construction., we use advanced forging technologies to manufacture durable components for demanding industries like construction, mining, and rail transit.

Key Steps in the Forge Process

- Heating: The metal is heated to make it soft and easier to shape without breaking.

- Shaping: Tools like hammers, presses, or molds are used to form the metal into the shape you want.

- Cooling: The metal is cooled carefully to lock in its new shape and keep it strong.

The History Behind Forging

Forging is a very old method, going back to like 4000 BC when people first figured out how to shape metal with fire and hammers. Back then, during the Bronze Age, folks made simple tools and weapons from metals like bronze and iron using basic hammers and anvils. It was all hands on, sweaty work by blacksmiths. Over time, things got fancier. The Industrial Revolution brought steam powered hammers, which made it way easier to churn out lots of forged metals. By the mid 1900s, we got super precise forging tech, perfect for making parts for cars and planes. Now, with high tech machines and automation, forging creates very detailed and tough parts for things like medical tools and defense gear. Its wild how far its come!

Common Forging Terminology Explained

Understanding forging starts with knowing its basic terms:

- Billet/Blank: A solid piece of metal, usually cast, that is ready to be shaped in the forging process.

- Die: A tool or mold used to form the metal into the desired shape.

- Punch: A tool that presses or cuts into the metal to shape or make holes.

- Hammer: A heavy tool that hits the metal to shape it. It can be manual or powered by a machine.

- Press: A machine that slowly applies steady pressure to shape the metal, unlike a hammer’s quick strikes.

- Flash: Extra metal that leaks out of the die during forging.

- Grain Flow: The way metal grains align during forging, which affects the part’s strength.

- Deformation: The change in the metal’s shape when it’s pressed or hit during forging.

Forging Methods and Their Applications

Choosing the right forging method depends on the part you are producing, the material you are working with, and the properties you need in the final product. Here is a breakdown of the most common forging techniques:

Open Die Forging

Open die forging is a process of deforming a piece of metal and it is done by placing metal in between two flat dies and shaped using pressure. The dies don’t fully enclose the material, so the metal spreads out and takes shape under the hammer or press.

This method is great for large, simple parts like shafts, blocks, and hubs. It is flexible and can handle large sizes, but it is not as precise for smaller, intricate components.

- Advantages: Offers flexibility in part size and shape, capable of producing large parts. Lower tool costs.

- Common Uses: Large, simple components like shafts, rings, and hubs.

- Industries: Construction, oil and gas, marine.

Closed Die Forging (Impression Die)

Closed die forging (also known as impression die forging) is one by placing the metal in a die cavity formed by two halves that fully enclose the material. The workpiece is then shaped under high pressure.

This process is ideal for creating parts with complex shapes and tight tolerances. It is often used in industries where high precision is required, such as automotive, aerospace, and defense. Components like gears, engine parts, and structural components are often made using this method.

- Advantages: Offers high precision, minimal waste, and excellent part strength.

- Common Uses: Automotive parts, aerospace components, precision gears, and engine components.

- Industries: Automotive, aerospace, defense.

Press Forging

Press forging uses a slow, controlled compression force applied to the metal between two dies, usually with a hydraulic press. This method is great for producing large components with consistent deformation.

Press forging method is particularly useful for parts that need uniformity and strength. Industries like heavy machinery manufacturing and aerospace often rely on press forging for parts that need to withstand high stresses.

- Advantages: Consistent material deformation, low defect rate, and enhanced strength due to controlled compression.

- Common Uses: Large parts that need to maintain a consistent shape, such as turbine blades and aircraft components.

- Industries: Aerospace, heavy machinery.

Drop Forging

In drop forging, a heavy hammer is dropped onto the metal placed in a die cavity. The hammer’s high impact forces shape the metal quickly and efficiently.

This method is perfect for mass production and is commonly used in the automotive industry for engine parts, tools, and fasteners. Forging dies are designed to allow excess material to be pushed outside of the impression, this is commonly known as flash material which is later removed in a trimming operation. A draft angle is also added to the impression to allow the material to release from the forging die after forming.

- Advantages: Ideal for high volume production, and very cost-effective for producing durable parts.

- Common Uses: Mass production of engine components, fasteners, and automotive parts.

- Industries: Automotive, manufacturing, heavy machinery.

Upset Forging

Upset forging is used to create parts with a thickened section at one end, like bolts or fasteners. It involves compressing the metal to increase its diameter while shortening its length. This process is widely used for creating parts that need strong, thick sections at their ends.

- Advantages: Allows for the production of strong, thick-ended parts at a relatively low cost.

- Common Uses: Fasteners, bolts, valve bodies.

- Industries: Construction, manufacturing.

Roll Forging

Roll forging or roll forming is a forging technique in which heated metal is passed between two rollers to reduce its thickness and length. It’s an efficient method for producing long, continuous parts like axles, leaf springs, and levers. The process results in a refined grain structure and reduces waste compared to other forging methods. Roll forging is usually performed hot. The precisely shaped geometry of grooves on the roll, forge the part to the required dimensions. The forging geometry of the rolls used to forge metal parts is only present over a portion of the roll’s circumference.

- Advantages: Reduced material waste, and improved mechanical properties due to refined grain structure.

- Common Uses: Long parts such as axles, leaf springs, and rods.

- Industries: Automotive, manufacturing.

Hanke Construction Machinery Manufacturing Co., Ltd. specializes in producing forged components such as shafts, sleeves, and excavator parts using advanced techniques like closed die forging and press forging. Our expertise supports critical sectors including construction machinery, mining, and rail transit.

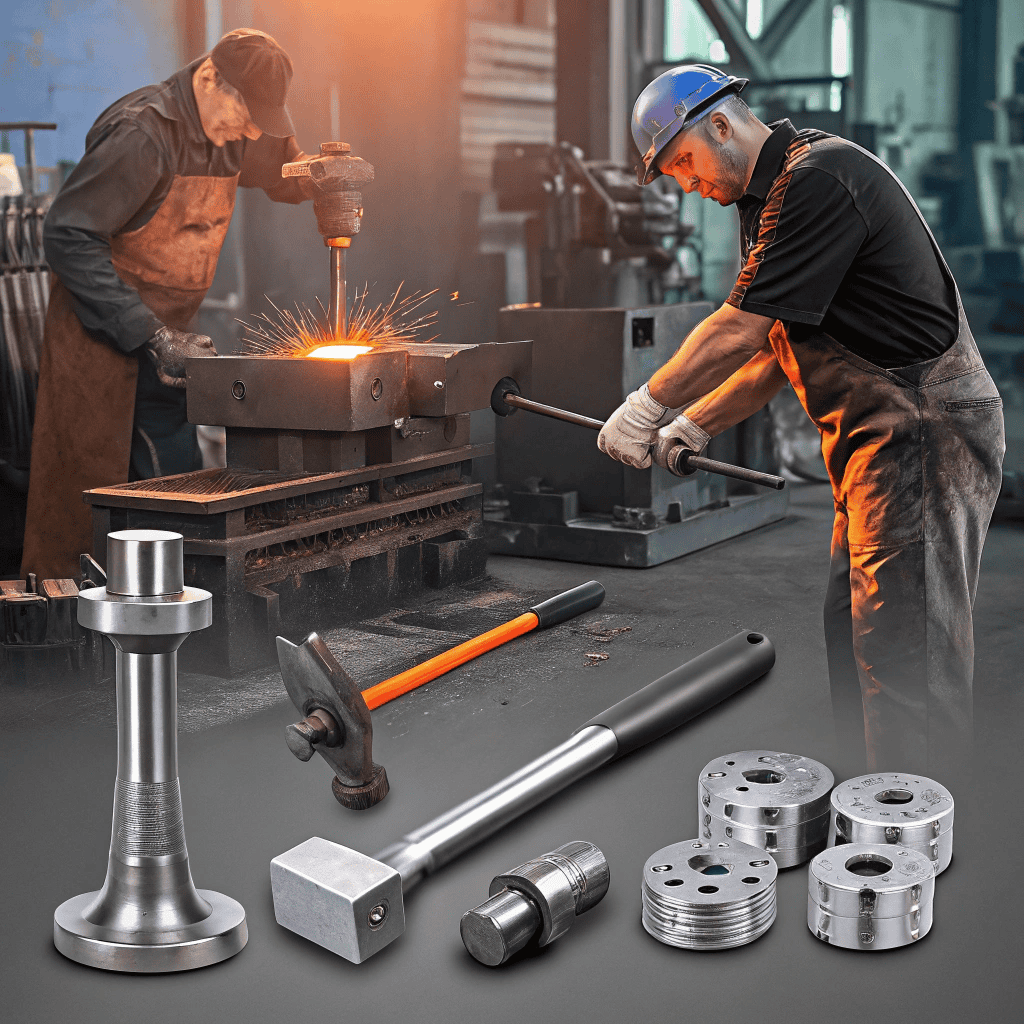

Forging by Tooling: Equipment & Tools

Current Status: Tools like dies, anvils, punches are mentioned but need more detail. The difference between manual and automated tooling is also not fully addressed.

Addition:

Forging Hammers vs. Presses:

- Hammers: Forging hammers use repeated impact force to shape the metal, ideal for parts that require significant deformation.

- Presses: Forging presses apply continuous force and are more suitable for parts needing gradual and uniform deformation.

Tool Types used in Forging Process:

- Dies: Dies are the molds or tools that shape the metal during forging. Custom dies are often made for specific parts.

- Anvils: Anvils are solid support structures where metal is placed for shaping, often used in manual forging.

- Punches: Punches are used to create holes or shape specific areas of the workpiece.

Manual vs Automated Tooling:

- Manual Tooling: Used for prototypes or smaller batches, often by hand or with simple machines.

- Automated Tooling: Used for mass production, often with robotic arms and precision machinery, ensuring speed and high accuracy.

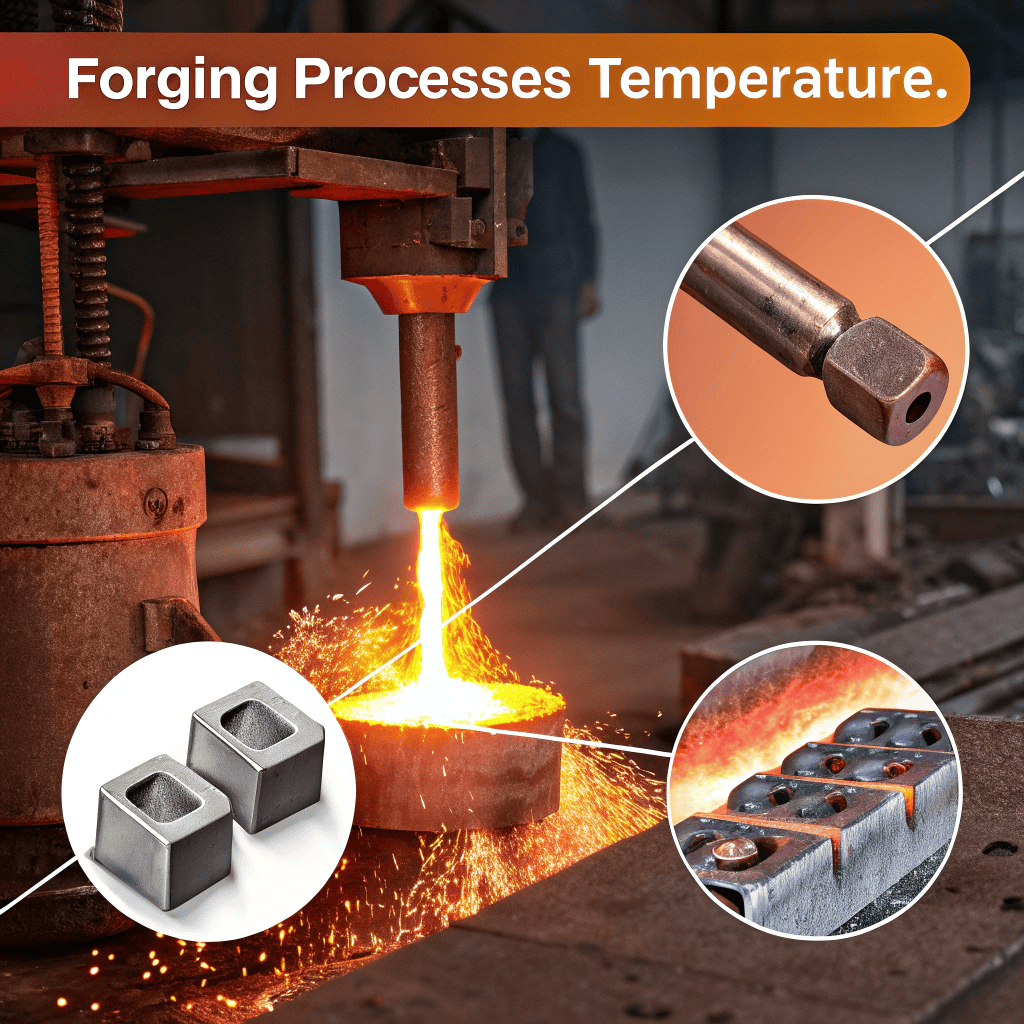

Forging Processes by Temperature

The temperature of large forgings is a critical technological parameter for improving the forming quality. Temperature significantly influences the forging outcome. Forging processes are typically classified as:

Hot Forging

- Temperature Range: 1,200–1,300°C (2,190–2,370°F).

- Benefits: Enhanced ductility, improved grain structure.

- Limitations: Less dimensional precision, surface oxidation.

- Materials: Steel alloys.

Warm Forging

- Temperature Range: Between cold and hot forging (~650–950°C).

- Benefits: Good balance of strength and formability, less die wear.

- Applications: Gears, shafts, connecting rods.

Cold Forging

- Temperature: Near room temperature (up to a few hundred °C).

- Benefits: Excellent surface finish, dimensional accuracy, low cost.

- Drawbacks: Risk of cracking, requires high tonnage.

- Materials: Aluminum, copper, soft steels.

Temperature vs Process

The temperature during forging greatly influences the properties of the final product. Let’s analyze each process:

| Process | Temperature Range | Surface Finish | Strength | Complexity | Notes |

| Cold Forging | < 200°C | Excellent | High | Low–Moderate | Best for strength and finish, limited to simple shapes |

| Warm Forging | 650–950°C | Good | Moderate | Moderate | Balanced option, good formability and decent strength |

| Hot Forging | 1,200–1,300°C | Fair | High | High | Ideal for complex shapes, but poorer finish and dimensional accuracy |

Key to Table Categories

- Surface Finish

- Excellent: Very smooth, minimal defects (Cold Forging)

- Good: Some oxidation or irregularities (Warm Forging)

- Fair: Rough surface, scaling (Hot Forging)

- Excellent: Very smooth, minimal defects (Cold Forging)

- Strength

- High: Very strong, often due to work hardening or heat treatment

- Moderate: Strong, but softened by heat

- High: Very strong, often due to work hardening or heat treatment

- Complexity

- Low–Moderate: Suitable for simple or moderately complex shapes

- High: Easily forms detailed or large complex parts due to softness of hot metal

- Low–Moderate: Suitable for simple or moderately complex shapes

Choosing the Right Forging Method

When selecting a forging method, there are several factors to consider:

- Material Type: Softer metals may be better suited for cold forging, while stronger materials might require hot forging.

- Production Volume: If you are making a lot of parts, methods like press forging or drop forging are more efficient.

- Precision Needs: For parts requiring tight tolerances, closed die forging or cold forging might be the best options.

- Cost: Cold forging is generally more cost-effective for smaller, complex parts, while press forging may be better for large volumes.

When to Choose Cold vs. Hot Forging:

- Cold Forging: Best for smaller, high precision parts like bolts or fasteners that require a smooth surface finish.

- Hot Forging: Ideal for larger, more complex parts where strength is the primary concern and a rougher finish is acceptable.

Future Trends in Forging Technology

As technology keeps improving, the future of forging looks very exciting. Here are some new ideas that will change the way we do forging:

- 3D Printing in Forging: Now 3D printing is being used in the forging industry, as it helps in making complex parts and dies that would be hard and time consuming to create using old forging methods.

- Robots and Automation: Robots are being used in forging to make the process simpler, faster, safer, and more accurate. Robots can do tasks easily like moving heavy materials, or setting up big machines, this allows people to focus on more important jobs.

- Smart Forging: New devices and sensors are being added to forging machines. These sensors track important things such as temperature and pressure, helping to make sure the process is just right. This technology helps make parts of better quality and increases production speed.

- AI and Machine Learning: AI or Artificial Intelligence is being used to make the forging process more smarter. AI is smart and can predict when the forging machine is broken and can adjust the process of forging to make it more efficient. This helps reduce downtime and make the process quicker and better.

- Integration of Industry 4.0 Technologies: The adoption of Industry 4.0 technologies is driving significant transformation in the forging market. Smart manufacturing systems, IoT-connected sensors, and advanced data analytics are increasingly being integrated into forging operations. These innovations aim to boost productivity, enhance equipment monitoring, and optimize overall production processes. Performing predictive maintenance, which helps to reduce downtime and improve overall operational efficiency, is made possible by the collection and analysis of data in real time.

These new technologies will help make forging faster, cheaper, and better in the future.

Conclusion

Metal forging remains a vital part of the manufacturing world, helping to produce some of the most critical components in industries like automotive, aerospace, and construction.

By understanding the different forging methods, forging terminology, and how temperature influences the process, you can make smarter decisions about which forging method to use for your next project.

Whether you are an engineer, a manufacturer, or just someone curious about metalworking, knowing the ins and outs of the forge process can give you a deeper appreciation for the strength and precision that goes into every forged part.

At Hanke Construction Machinery Manufacturing Co., Ltd., we don’t just forge metal, we forge the future. Every shaft, sleeve, and component we produce is built to power progress, drive innovation, and support the industries that shape the world.

If you’re looking to source high-quality forged parts from industry experts, you’re in the right place. Our team is ready to deliver precision-engineered components tailored to your needs.

Frequently Asked Questions

What are the main types of forging?

There are several types of forging: Open Die Forging, Closed Die Forging, Drop Forging, Press Forging, Upset Forging, and Roll Forging.

What is the difference between hot and cold forging?

Hot forging is done at high temperatures, ideal for large, complex parts. Cold forging occurs at room temperature and is used for high precision, small parts.

What tools are used in forging?

At Hanke Construction Machinery Manufacturing Co., Ltd. the main tools used in forging include hammers, presses, dies, anvils, and punches.

How is forging classified by temperature?

Forging can be classified as hot, warm, or cold, based on the temperature at which the metal is processed.