Metalworking is one of the coolest crafts out there, going way back thousands of years. In places like China, we have been casting metals for over 2,400 years. Over time, we have gotten really good at shaping metals like aluminum to make them stronger, tougher, or easier to work with. One of the best ways to do this is through heat treatment, especially something called aluminum solution heat treatment. It is a game changer for making parts that are light but super strong. Whether you are building a car, an airplane, or even a baseball bat, heat treatment is how you get aluminum ready for the job.

Here we will break down what aluminum solution heat treatment is, the key words you need to know, and the six main ways to do it. We will also talk about what affects the process, why it is so awesome, and where you will see heat-treated aluminum in action. If you are new to this or just want to get the full picture, this guide will keep it simple and fun.

Understand Aluminum Heat Treatment

If your question is how to heat treat aluminum, here is a simple answer. Heat treatment is all about changing aluminum to make it perfect for what you need. You heat it up, cool it down, and sometimes let it sit to tweak its strength, flexibility, or durability. Unlike steel, aluminum needs its own special approach because it is often mixed with other metals like copper or magnesium to form alloys. These alloys are what make aluminum so versatile, and Aluminum Solution heat treatment brings out their best qualities. At Hanke Construction Machinery Manufacturing Co., Ltd, we use top-notch heat treatment techniques to create super strong aluminum parts for industries like aerospace, automotive, spare parts, and construction.

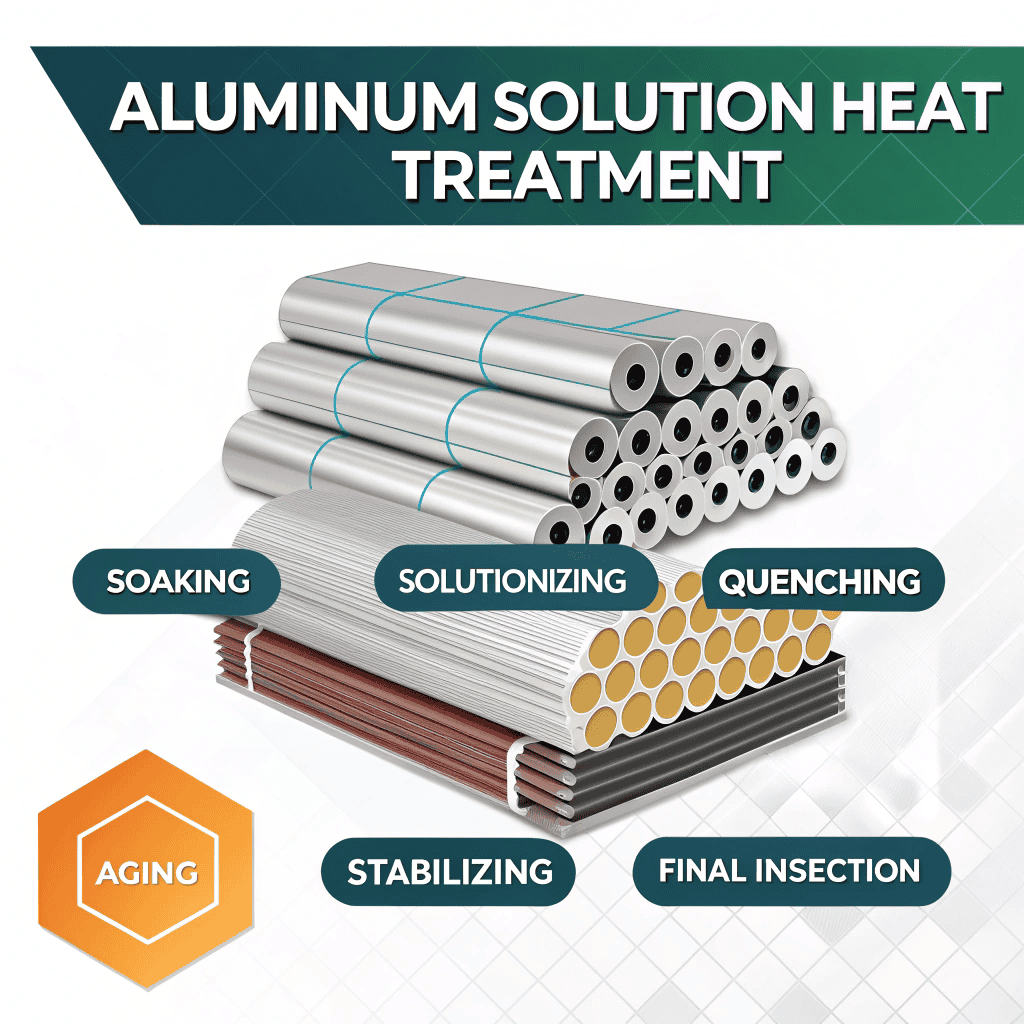

Key Steps in the Aluminum Solution Heat Treatment Process

- Heating: You warm up the aluminum to a specific temperature to make it ready for shaping or strengthening.

- Cooling: You cool it down, sometimes fast, sometimes slow, to lock in the changes.

- Heat Treatment Aging: Some processes let the metal sit or heat it gently to boost its strength over time.

The History Behind Aluminum Heat Treatment Aging

Metal aging is used on solution heat treated alloys in order to increase their strength and hardness, while reducing their ductility. This can be done naturally—simply by letting the metal alloy hang out for years on end—or it can be done artificially. Heat treating metals isn’t new, it goes back thousands of years. Heat treatment aging is way back around 4000 BC, people were already heating and hammering metals like bronze to make tools and weapons. Aluminum came later, though, since it is trickier to extract from ore. By the 1800s, scientists figured out how to produce aluminum, and by the early 1900s, they were experimenting with heat treatment to make it stronger. The big breakthrough came during World War II when aerospace industries needed lightweight but tough materials for planes. That is when aluminum solution heat treatment aging became huge. Now, with modern tech like computer-controlled furnaces, we can heat treat aluminum with crazy precision to make parts for rockets, cars, and even sports gear. It is amazing how far this craft has come!

Common Heat Treatment Terminology Explained

Before we learn about the processes of how to heat treat aluminum, let’s get you up to speed on some key words you will hear in aluminum heat treatment:

- Alloy: Aluminum mixed with other metals like copper, magnesium, or zinc to make it stronger or more durable.

- Solution Heat Treatment: Heating aluminum to mix alloying metals evenly, then cooling it fast to lock them in place.

- Precipitates: Tiny particles that form inside the metal during aging, making it harder and stronger.

- Aging: The process of holding metals at room temperature or at a predetermined temperature for the purpose of increasing their hardness and strength by precipitation; aging is also used to increase dimensional stability in metals such as castings

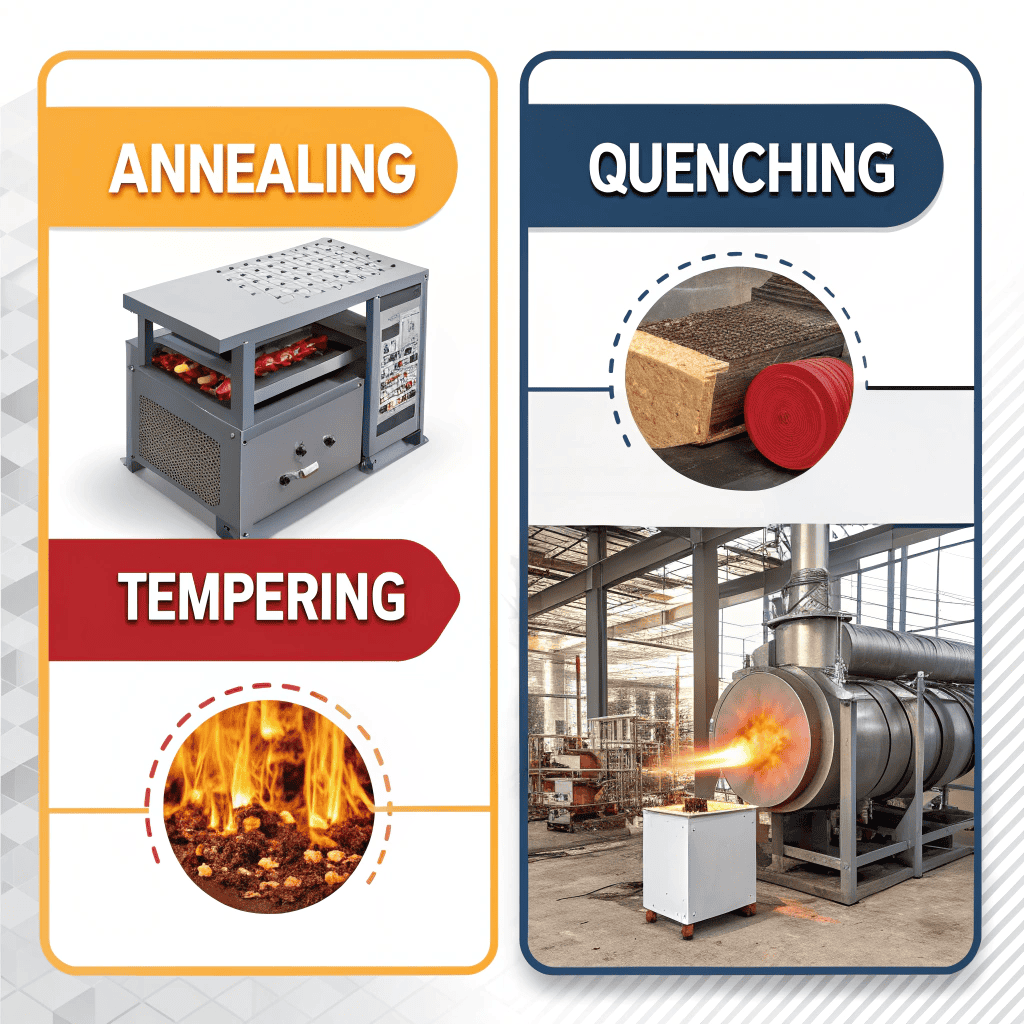

- Quenching: Cooling the metal quickly, usually in water or oil, to trap its structure.

- Annealing: Heating and cooling the metal slowly to make it softer and easier to shape.

- Grain Structure: The way metal particles are arranged inside, which affects strength and toughness.

Aluminum Solution Heat Treatment Methods and Their Applications

There are six main ways to heat treat aluminum, and each one does something different to the metal. Choosing the right one depends on what you are making, the alloy you are using, and whether you need the metal hard, soft, or somewhere in between. Here is a breakdown of the “Big 6” methods of how to heat treat aluminum:

Aluminum Solution Heat Treatment

This is the starting point for a lot of aluminum alloys, like 6061 and 7075, which are used in tough jobs like airplane parts or car parts. You heat the aluminum to a super high temperature, around 450 to 550 degrees Celsius, until it is hot but not melted. This heat lets alloying metals like copper or magnesium mix evenly into the aluminum, like dissolving sugar in hot water. Then, you cool it fast, usually by dunking it in cold water. This quick cooling locks those metals in place, setting the stage for more treatments like aging. It is perfect for parts that need to be strong but light, like aerospace components.

- Advantages: Prepares alloys for strength, works with many alloys, sets up for aging.

- Common Uses: Airplane wings, car frames, structural parts.

- Industries: Aerospace, automotive, construction.

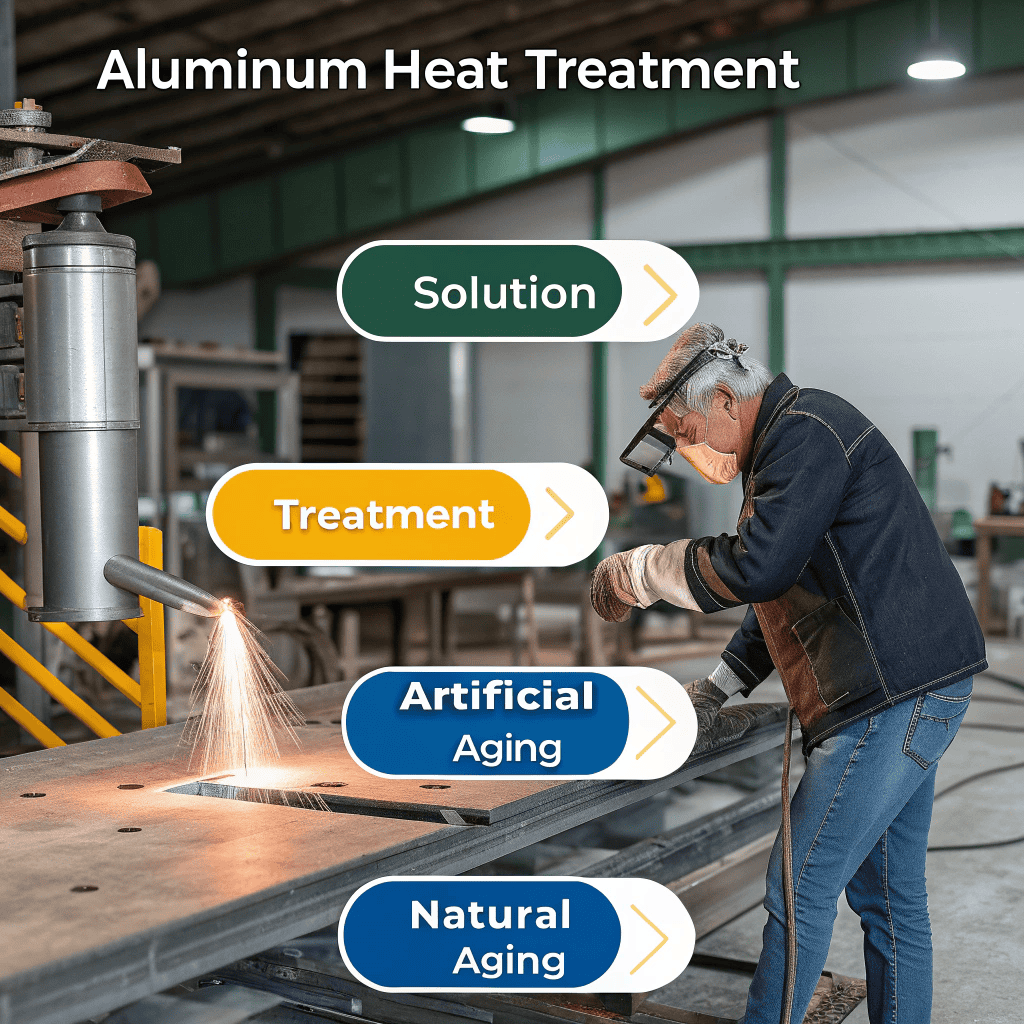

Precipitation Hardening (Artificial Aging)

After solution heat treatment, the aluminum isn’t at its strongest yet. Precipitation hardening, or artificial aging, takes it to the next level. You heat the metal again, but at a lower temperature, around 120 to 190 degrees Celsius, for a few hours. This lets tiny particles called precipitates form inside the metal. These particles act like little barriers, stopping defects from moving and making the metal harder and stronger. This is how you harden aluminum for stuff like bike frames or engine parts. The main strengthening phases in Al–Li alloys are formed and stabilized during artificial aging.

- Advantages: Boosts strength fast, great for high-performance parts.

- Common Uses: Bike frames, engine components, aerospace parts.

- Industries: Automotive, aerospace, sports equipment.

Natural Heat Treatment Aging

Some alloys, like 2024, get stronger just by sitting at room temperature. This is called natural aging. It is slower, taking days or weeks, but it doesn’t need extra heat or equipment. The same precipitates that form in artificial aging show up over time, just at a chill pace. It is great for parts that don’t need to be super strong right away, like components waiting to be assembled.

- Advantages: No extra heating, low cost, easy for some alloys.

- Common Uses: Aerospace components, parts in storage.

- Industries: Aerospace, manufacturing.

Artificial Aging

Precipitation hardening is the mechanism where the hardness, yield strength, and ultimate strength dramatically increases with time at a constant temperature (the aging temperature) after rapidly cooling from a much higher temperature (solution heat treat temperature). Artificial aging is just precipitation hardening by another name, but it is worth mentioning again because it is so important. It speeds up the strengthening process by heating the aluminum to a controlled temperature for a set time. This is how alloys like 6061-T6 get their toughness for things like push wheels or aircraft frames. It is fast and reliable, perfect for industries that need strong parts quickly.

- Advantages: Fast strength boost, precise control, high durability.

- Common Uses: Car wheels, structural components, tools.

- Industries: Automotive, aerospace, construction.

Annealing

Sometimes you don’t want aluminum to be hard, you need it soft and easy to bend or shape. That is where annealing comes in. You heat the metal to a moderate temperature, around 300 to 400 degrees Celsius, and then let it cool slowly, often in the air. This relaxes the metal’s internal stresses, making it flexible and easier to work with. It is perfect for shaping complex parts like car hoods or decorative panels.

- Advantages: Makes metal soft, easy to shape, reduces cracking.

- Common Uses: Car body panels, molded parts, tooling plates, decorative pieces.

- Industries: Automotive, manufacturing, art.

Homogenizing

Homogenizing is mostly for cast aluminum, where alloying metals can clump unevenly during casting, creating weak spots. You heat the metal to a high temperature, close to its melting point, for several hours. This lets the alloying metals spread out evenly, like stirring a pot of soup. Then, you cool it carefully to lock in that even structure. It is great for making cast parts stronger and more consistent, like engine blocks.

- Advantages: Evens out alloy structure, boosts strength, reduces weak spots.

- Common Uses: Engine blocks, cast parts, heavy machinery components.

- Industries: Automotive, heavy machinery, manufacturing.

At Hanke Construction Machinery Manufacturing Co., Ltd, we specialize in heat treating aluminum alloys like 6061 and 7075 to create tough, lightweight parts for aerospace, automotive, and more. Our expertise ensures every component is built to last.

Heat Treatment by Tools and Equipment

The term “heat treating” for aluminum alloys is frequently restricted to the specific operations employed to increase strength and hardness of the precipitation-hardenable wrought and cast alloys. These usually are referred to as the “heat-treatable” alloys to distinguish them from those alloys in which no significant strengthening can be achieved by heating and cooling. To do aluminum solution heat treatment, you need the right tools. Here is what is used:

- Furnaces: Ovens that heat aluminum to precise temperatures, often computer-controlled for accuracy.

- Quenching Tanks: Containers filled with water, oil, or other liquids to cool the metal fast.

- Aging Ovens: Lower-temperature ovens used for artificial aging to form precipitates.

- Thermometers and Sensors: Tools to monitor temperature and ensure the process is just right.

Manual vs. Automated Equipment:

- Manual: Smaller setups, like basic furnaces, used for prototypes or small batches.

- Automated: High-tech furnaces and robotic systems for mass production, ensuring speed and precision.

Heat Treatment Processes by Temperature

Metal heating processes have been used since the ancient times. Back in the days, blacksmiths heat-treated metal to shape it into horseshoes, or wagon parts. And as the years go by, heating metal remains the most effective way to form it into the desired shape.

Temperature is a big deal in heat treatment, it changes how the aluminum turns out. Here is how the main processes of solution aluminum heat treatment stack up:

| Process | Temperature Range | Strength | Flexibility | Complexity | Notes |

| Solution Heat Treatment | 450–550°C | Moderate | Low | High | Mixes alloys evenly, needs fast cooling, sets up for aging. |

| Precipitation Hardening | 120–190°C | High | Low | Moderate | Boosts strength fast, great for tough parts like gears or frames. |

| Annealing | 300–400°C | Low | High | High | Makes metal soft, perfect for shaping complex parts. |

| Homogenizing | Near melting point | Moderate | Low | Low–Moderate | Even out cast alloys, used for heavy parts like engine blocks. |

Key to Table Categories

Strength:

- High: Super tough, like after precipitation hardening.

- Moderate: Decent strength, like after solution heat treatment.

- Low: Soft and flexible, like after annealing.

Flexibility:

- High: Easy to bend or shape, like annealed aluminum.

- Low: Stiff and strong, like hardened alloys.

Complexity:

- High: Can handle complex processes or parts.

- Low to Moderate: Best for simpler shapes or prep steps.

Choosing the Right Heat Treatment Method

Picking the best aluminum Solution heat treatment depends on a few things:

- Alloy Type: Some alloys, like 7075, get super strong with aluminum solution heat treatment and aging, while others stay softer.

- Part Size: Big parts might need homogenizing, while small ones can use annealing or aging.

- Strength Needs: Want it tough? Go for precipitation hardening. Need it to be flexible? Try annealing.

- Production Speed: Artificial aging is fast, while natural aging takes time but saves energy.

When to Choose Each Method:

- Solution Heat Treatment: Best for prepping alloys like 6061 or 7075 for strength.

- Precipitation Hardening: Ideal for high-strength parts like aerospace components.

- Annealing: Perfect for soft, bendable parts like car panels.

- Homogenizing: Great for cast parts that need even strength.

Future Trends in Aluminum Heat Treatment

Demand for heat treatment services and equipment is expanding at a higher global rate (5 to 6%) compare to rest of economic activities (0.5 to 1.5%). The high growth rate leads to an increasing number of furnace manufacturers and creates intensive competition amongst furnace manufacturers.

The future of heat treatment is looking pretty exciting. Here is what is coming:

- Smart Furnaces: New furnaces with sensors track temperature and cooling in real time, making parts more consistent.

- Automation: Robots are taking over tasks like moving hot metal or setting up furnaces, making the process faster and safer.

- AI in Heat Treatment: Artificial intelligence can predict when equipment might fail or adjust temperatures for better results.

- Green Tech: New methods are cutting energy use, like using solar-powered furnaces or recycling heat.

These advancements are making aluminum solution heat treatment quicker, cheaper, and better for the planet.

Conclusion

Aluminum solution heat treatment is a big deal in manufacturing, turning this lightweight metal into something strong, flexible, or corrosion-resistant for industries like aerospace, automotive, and sports. By understanding the Big 6 methods, solution heat treatment, precipitation hardening, natural aging, artificial aging, annealing, and homogenizing, you can pick the right one for your project. Knowing how alloy type, temperature, cooling speed, and cooling method affect the process helps you get the perfect part every time. Many years of experience provided by our engineers, the continuous further developments in our technologies and the comprehensive, certified quality management system are proof of Hanke Construction Machinery Manufacturing Co., leading role in the world market.

At Hanke Construction Machinery Manufacturing Co., Ltd, we don’t just heat treat aluminum, we shape the future. Every part we make is built to drive innovation and power industries around the world. If you are looking for premium quality heat treated aluminum parts, our team is ready to deliver exactly what you need.