A stainless steel casting crucible is a container that holds and melts metal. Foundries use it when making parts. It must stand up to very high heat.

Crucibles matter because they keep melted metal clean. They also stop damage from heat and air. This makes casting safer and more accurate.

In this guide, you will learn what stainless steel crucibles are, how we can make them, and which grades work best. You will also see how investment casting and silica sol improve their strength and quality.

What Is a Stainless Steel Casting Crucible?

Crucibles are defined as potentially movable reaction vessels in which high-temperature transformations take place, but with no permanent unidirectional airflow; it is the latter condition that separates them from furnaces

A stainless steel casting crucible is a strong pot made from stainless steel. It is used to melt and hold metal at high heat. Foundries and shops use it in the casting process.

Other crucibles are made from ceramic or graphite. Ceramic crucibles can break under stress. Graphite crucibles wear out faster. Stainless steel crucibles last longer and work with many metals.

The main benefits are strength, long life, and resistance to heat and corrosion. They can also be made in many sizes and shapes. This makes them useful for many industries.

Investment Casting of Stainless Steel Crucibles

Investment casting is a method used to make stainless steel crucibles. The process uses a wax model of the part. The model is coated with ceramic, then melted away to leave a mold. Molten stainless steel is poured into the mold to form the crucible.

One type is the silica sol method. It gives a smoother surface and better detail. This reduces cracks and improves the crucible’s strength.

Factories use investment casting for crucibles because it gives high accuracy. The shape is precise, and the surface is clean. This helps when crucibles are used in aerospace, auto, and chemical industries.

High-Temperature Resistant Steel Crucibles

A stainless steel casting crucible can withstand very high heat. The level of heat depends on the grade of steel. Most stainless steel crucibles work between 1,000°C and 1,600°C.

Three things affect performance: oxidation, corrosion, and thermal cycling. Oxidation happens when heat and air touch the steel. Corrosion comes from contact with chemicals or molten metal. Thermal cycling means heating and cooling many times. This can make the crucible weaker.

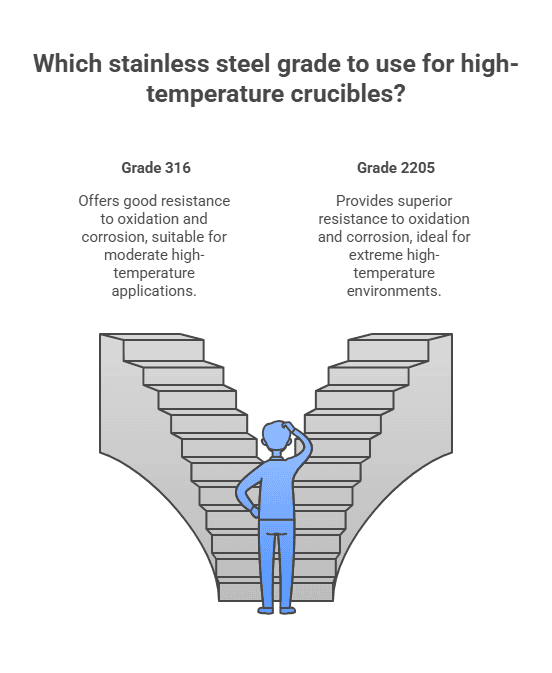

In tough jobs, like aerospace and energy plants, crucibles face long hours of heat. Stronger grades, such as 316 and 2205, resist these conditions better.

Stainless Steel Casting Grades for Crucibles (304, 316, 2205)

A stainless steel casting crucible can be made from different grades of steel. The most common grades are 304, 316, and 2205. Each grade has its own strengths, limits, and best uses.

304 Stainless Steel

Grade 304 is the most common and lowest cost option. It has good strength and fair resistance to rust. It can handle high heat in air up to about 870°C with breaks and 925°C in steady use.

It is often used for general casting jobs, such as melting aluminum, zinc, or copper. It works well when the melt is clean and not rich in salts or chemicals.

316 Stainless Steel

Grade 316 has the same base as 304 but adds molybdenum, which makes it resist rust and pitting much better. It also handles salt, moisture, and mild acids better than 304.

Like 304, it can handle air heat up to 870–925°C. Buyers use it when crucibles face harsh chemicals or fluxes. It costs more than 304 but lasts longer in tough jobs.

2205 Duplex Stainless Steel

Duplex stainless steel is a family of stainless steel that is made of austenitic steel and ferritic steel in nearly equal proportions. This type of stainless steel is both stronger and more resistant to corrosion than your typical types of stainless steel. Duplex stainless steel is also more ductile than ferritic grades, however, it is not quite as ductile as the austenitic grades.

Grade 2205 is a duplex stainless steel, which means it is very strong and very resistant to rust, even in salt water or acid. It has the best corrosion resistance of these three grades.

But 2205 is not good for very high heat. If it is used above 300°C for a long time, it can lose strength and crack. For this reason, it is best for lower-heat jobs where strong rust resistance is more important than heat resistance.

Comparison Table

When comparing the melting points of steel alloys, the number is usually given in a range due to the variations used in the metals used in the production. That number also relates to the metals’ resistance to stress, corrosion, cracking, and other attributes.

| Grade | Strength | Rust Resistance | Heat Resistance | Cost |

| 304 | Good | Moderate | High (to ~925°C) | Low |

| 316 | Higher | Strong | High (to ~925°C) | Medium |

| 2205 | Very High | Very Strong | Low (≤300°C) | High |

- Use 304 for general work at lower cost.

- Use 316 when crucibles face chemicals, salts, or harsh flux.

- Use 2205 when corrosion resistance is critical, but only at moderate heat.

- For very high heat above 1,000°C, buyers often move to special heat grades like 309 or 310, not 304, 316, or 2205.Silica Sol Investment Stainless Steel Crucibles

The silica sol method is a way to make stainless steel crucibles. It uses a liquid called silica to build the mold. This makes the crucible smooth and strong.

Silica sol casting has many good points. It stops tiny holes from forming. It also makes the crucible harder and more accurate. The smooth surface needs little work after casting.

Many industries use silica sol crucibles. They are common in aerospace, car-making, and chemical plants. These crucibles last longer and work well in tough heat.

How to Select the Right Stainless Steel Crucible

The best approach is to begin with your own detailed assessment of your operations. You need to fully document and, where possible, quantify all aspects of your melting, holding and metal handling processes. These include:

Check the Heat Range

Thermal compatibility is a concern with materials that melt during evaporation. Molten materials conform to the shape of the crucible. After the deposition when the melt solidifies, differences in thermal expansion rates can cause the crucible to crack.

The first step is to look at how much heat the crucible must handle. Some metals melt at lower heat, while others need very high heat. A crucible must match the melting point of the metal. If the crucible is too weak, it may fail or break.

Hanke Engineering offers metal liners which can withstand the difference in thermal expansion without cracking. If you desire to run the source material without using a metal liner, one solution is to use a limited amount of source material so that the bottom of the crucible is not covered.

Pick the Right Steel Grade

Different grades of stainless steel work in different ways:

- 304 is fine for normal casting.

- 316 is better when the crucible touches chemicals, salt, or moisture.

- 2205 is the best for very high heat and heavy use.

Choosing the right grade helps the crucible last longer and stay safe in tough jobs.

Think About Cost and Value

Price is always important. A crucible made from higher grades may cost more. But it also lasts longer and needs fewer replacements. This saves money over time. Buyers should balance cost with the benefits of longer service life.

Plan for Service Life

Every crucible wears down after use. Some last longer if cared for well. Buyers should plan how often the crucible will be used and for how long. This helps in picking the best grade.

Care and Maintenance

Good care makes crucibles last longer. Do not heat them too fast or cool them too quickly. This may cause cracks. Clean them often to stop buildup of metal or chemicals. Store them in a dry place to avoid rust.

When to Choose Stainless Steel

Stainless steel crucibles are the best choice when strength and safety matter most. They are better than ceramic or graphite when work needs high heat, long life, and strong resistance to damage.

When choosing a supplier, it also helps to look for partners who can support you beyond just the product. For example, companies like Huasuma provide stainless steel casting solutions. The company holds multiple national patents, participates in developing industry standards, and exports to over 60 countries worldwide.

Applications & Industry Use Cases

Foundries

Foundries melt and shape metal to make parts. They need crucibles that can handle high heat many times a day. Stainless steel crucibles work well because they last long and do not break easily. This helps foundries keep production steady.

Aerospace and Defense

The aerospace and defense industry uses special metals like titanium and superalloys. These metals need very high heat to melt. A stainless steel casting crucible is strong enough to hold these metals without cracking. This makes it safe for making airplane and rocket parts.

Automotive Industry

Car makers use stainless steel crucibles to cast parts that must be both light and strong. These crucibles give clean results and keep the metal pure. This is important when making safe and reliable parts for vehicles.

Electronics and Specialty Materials

Electronics need clean and precise metal parts. Even small errors can cause problems in devices. Stainless steel crucibles help keep metals pure during melting. They are used to make parts for computers, phones, and special equipment.

Energy and Power

The energy industry also needs strong crucibles. Nuclear plants, renewable energy, and chemical plants all work with metals that face heat and corrosion. Stainless steel crucibles resist both, making them a trusted choice in these fields.

Chemical Industry

Many chemical plants use metals that react with acids or salts. Crucibles made from stainless steel grades like 316 or 2205 are resistant to these harsh conditions. This makes them safer and longer-lasting for daily use.

Conclusion

A stainless steel casting crucible is an important tool in many industries. It melts and holds metal at very high heat. This keeps the casting job safe and clean.

Stainless steel crucibles are stronger than ceramic or graphite. They last longer, resist rust, and can handle heating and cooling many times. Grades like 304, 316, and 2205 give buyers choices. Each grade has its own mix of cost, strength, and heat resistance.

New methods like investment casting and silica sol casting make crucibles better. These methods give smooth surfaces and fewer weak spots. This helps industries get clean and accurate parts.

Today, all companies use stainless steel crucibles. They choose them because they stay strong under stress and keep metal pure.

If you need crucibles that last long and work better, stainless steel is the right choice. Contact us today to learn more. Our team can help you choose the best grade and process for your project.

FAQs

Q1. What is the best grade of stainless steel for crucibles?

The best grade depends on the job. Grade 304 is good for normal use. Grade 316 is better when chemicals are present. Grade 2205 is best for very high heat and tough work.

Q2. How long does a stainless steel crucible last?

The life of a crucible depends on use and care. With good care, it can last many cycles before it needs replacing.

Q3. Can stainless steel crucibles hold molten aluminum, zinc, or copper?

Yes. Stainless steel crucibles can handle these metals. The right grade makes the crucible last longer when used with each metal.

Q4. Is silica sol investment casting better than older methods?

Yes. Silica sol casting makes crucibles smoother, stronger, and more accurate. It also reduces weak spots and cracks.

Q5. What industries use stainless steel crucibles the most?

They are common in foundries, aerospace, automotive, electronics, energy, and chemical plants. These industries need crucibles that resist heat and corrosion.