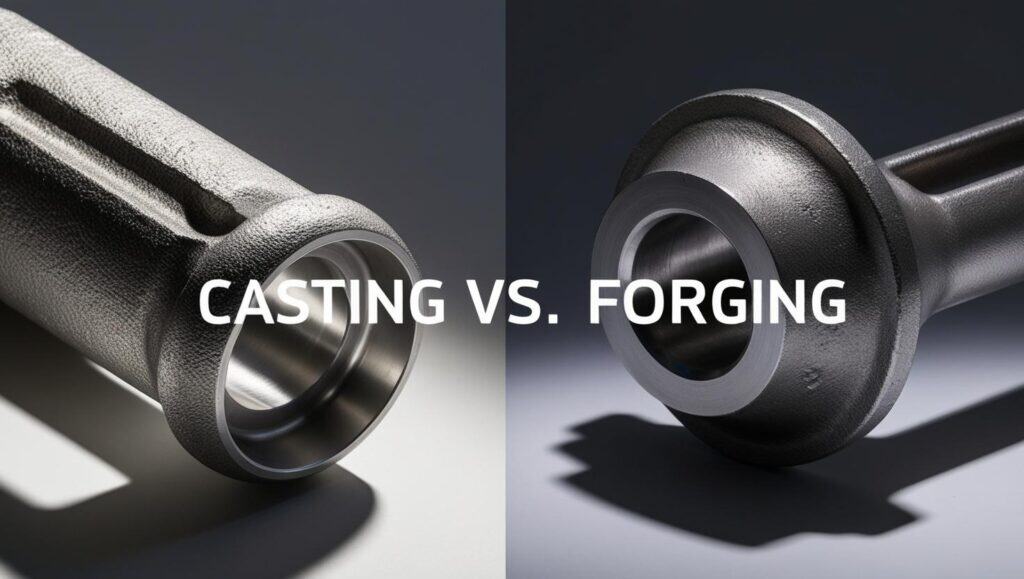

Metal parts are used in almost everything from cars and planes to tools and machines. But how are these metal parts made? Two common methods are foundry (also called casting) and forging.

These are both ways to shape metal, but they are very different. Knowing the difference can help you choose the right method for your project. You might be making something strong or something with a tricky shape.

In this guide, we’ll explain what each process does, how they work, and when to use them. You’ll also see real-life examples and an easy chart that compares them side by side.

What Is a Foundry Process?

Foundries produce metal products (called castings or castings) of well-defined shape, size and chemical-physical characteristics through a simple and energy-efficient production process.

How the Casting Process Works

Let’s break it down into simple steps:

- Melting the Metal: First, the metal is heated in a furnace until it becomes a hot liquid.

- Pouring into Molds: The liquid metal is carefully poured into a mold. This mold is shaped like the final part you want to create.

- Cooling and Solidifying: As the metal cools, it hardens inside the mold. This step can take a few minutes to several hours, depending on the metal and shape.

- Post-Processing: Once it’s solid, the part is removed from the mold. Workers might trim off extra material, clean the surface, or do heat treatments to improve strength.

Common Casting Methods

There are different ways to cast metal. Some of the most popular include:

- Sand Casting: This uses a special type of sand to create molds. It’s great for large, simple parts and is cost-effective.

- Investment Casting: This method uses a wax model coated with ceramic. It gives very precise, detailed shapes. It’s often used for aerospace and medical parts.

Each casting method has its own strengths. In general, casting is best when you need complex shapes that might be too hard or expensive to make any other way.

What Is Forging?

Forging is the manufacturing process of hammering, pressing or rolling metal into shape. This is either delivered from a hammer, press or die. It is essentially the art of heating and working hot metal to design or shape that is fit for a specific purpose or use.

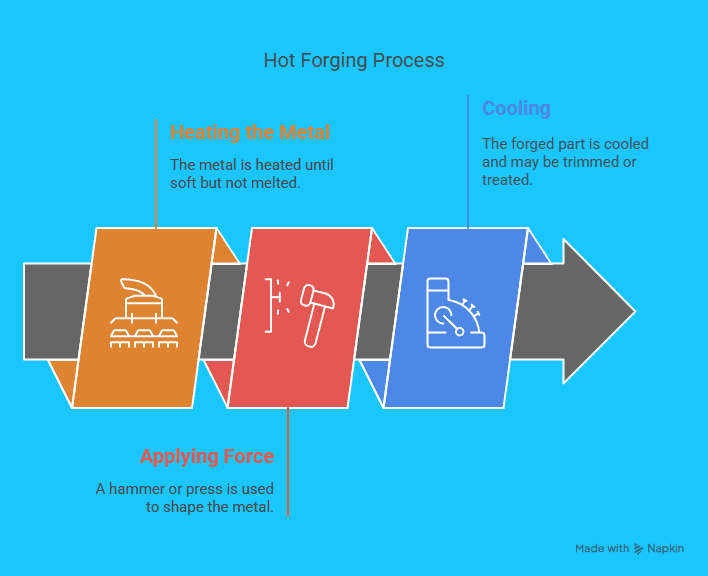

How the Forging Process Works

Here’s a simple breakdown of the steps:

- Heating the Metal (Only in Hot Forging): In hot forging, the metal is heated until it’s soft but not melted. This makes it easier to shape.

- Applying Force: Once the metal is ready, a hammer or press is used to push it into a die (a shaped mold made of metal). This force changes the metal’s shape.

- Cooling: After shaping, the forged part is cooled and may be trimmed or treated for better performance.

Hot vs. Cold Forging

- Hot Forging: The hot forging temperature varies depending on the type of metal. Hot forging starts with heating the dies to prevent any temperature loss and ensure crystallization doesn’t occur until forming is complete. Heating causes the metal to become more ductile. When the pressure of the dies squeezes the hot metal, the structure transforms into a more refined grain that results in increased yield strength and ductility.

- Cold Forging: Cold forging uses a displacement process to shape the material into the desired shape. Compressive force squeezes the metal between a punch and die at room temperature until the material conforms to the die’s contours. Cold forging techniques include rolling, pressing, drawing, spinning, heading, and extruding.

Die Types in Forging

- Open-Die Forging: The metal is not fully enclosed in the mold. It’s used for larger, simpler parts.

- Closed-Die Forging: The metal is completely trapped in the mold. This gives more accurate shapes and is often used in high-volume production.

Forging is often used when you need strong, durable parts. Because the metal grains are forced to flow along the shape, the final piece is tougher and better at handling stress.

Key Differences Between Forging and Foundry

Now that you know how forging and foundry (casting) work, let’s compare them side by side. This will help you quickly understand which process fits your needs.

Forging vs Foundry: Comparison Table

| Aspect | Foundry (Casting) | Forging |

| Process | Melt metal and pour into a mold | Use force to shape solid metal |

| Material Structure | May have tiny holes or weak spots (porosity) | Dense, with aligned grain structure (stronger) |

| Shape & Design | Great for complex, curved, or hollow shapes | Best for simple, solid shapes that need strength |

| Applications | Engine blocks, pump housings, art sculptures | Crankshafts, gears, hand tools, aerospace parts |

| Cost | Lower tooling cost for small batches | Higher initial tooling cost but better performance |

| Strength | Not as strong due to internal flaws | Very strong and fatigue-resistant |

Real-Life Examples

Let’s say you’re building a car engine:

- The engine block is usually cast. Why? Because it has complex curves, chambers, and needs to be lightweight.

- The crankshaft, on the other hand, is forged. It handles a lot of stress and spinning force, so it needs to be super strong.

Another example is in aerospace:

- Complex parts like turbine housings are cast.

- Landing gear or structural brackets are forged for strength and safety.

If your part needs to survive high stress, pressure, or repetitive use, forging is usually the better choice. If your part has complex shapes, tight corners, or hollow spaces, casting is often easier and cheaper.

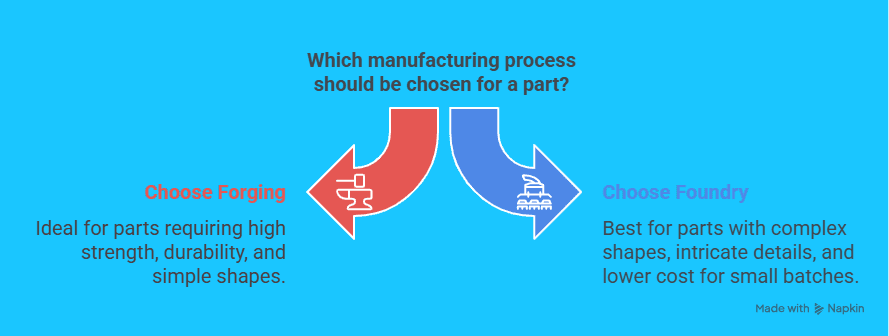

When to Choose Forging or Foundry?

So, when should you choose forging, and when is foundry (casting) the better option? It really depends on what you need from your part. Let’s look at a few simple rules that can help you decide.

Choose Forging When:

- You need strength. Forged parts are tougher and handle more pressure.

- The part will move a lot. Think crankshafts, gears, and tools that face wear and tear.

- You want low porosity. Forging reduces tiny air pockets, making the part safer and longer-lasting.

- The shape is simple. Forging works best with parts that aren’t too complex.

Choose Foundry (Casting) When:

- The part has a complex shape. Casting lets you make curves, holes, and thin walls easily.

- You need lots of detail. Intricate designs are easier to cast.

- You want lower cost for small batches. Tooling is cheaper for short runs.

- The part won’t take much stress. Things like pump housings or covers are good casting choices.

Industry Use Cases

- Automotive: Cast for engine blocks, forged for suspension parts and crankshafts.

- Aerospace: Cast for turbine blades, forged for structural support components.

- Mining & Oil/Gas: Forging is often chosen for drill bits, shafts, and valves that handle high pressure.

- Marine Equipment: Casting is used for large housings; forging is preferred for key load-bearing parts.

Advantages and Disadvantages

Both forging and foundry (casting) have their own benefits and downsides. Let’s look at them side by side so you can see what fits your needs better.

Advantages of Forging

- Very strong and durable parts

- Excellent for parts under high stress or load

- Low porosity – fewer weak spots or cracks

- Better grain structure, which means longer part life

- Often used in safety-critical applications

Disadvantages of Forging

- Higher initial cost for tooling and equipment

- Not ideal for complex or hollow shapes

- Limited design flexibility

- May need more machining after forging

Advantages of Foundry (Casting)

- Great for complex shapes and detailed designs

- Can create hollow or curved parts easily

- Lower cost for small production runs

- Good for large parts that are hard to machine

Disadvantages of Foundry (Casting)

- More likely to have porosity or small cracks

- Weaker than forged parts under pressure

- May need more inspections or testing

- Can have surface defects or rough finishes

FAQ Section

Is forging more expensive than casting?

Yes, in most cases it is. When you choose forging, you’ll need strong tools, dies, and heavy equipment, which can cost more up front. But forged parts are stronger and last longer, especially under stress. So, while forging costs more at the start, it can save you money in the long run by reducing part failure.

Can you forge all metals?

Not all metals can be forged. You can forge metals like steel, aluminum, titanium, and copper because they’re strong and can handle pressure. But some metals, like cast iron or lead, are too brittle or soft. These are better shaped using casting instead of forging.

What are examples of forged vs. cast parts?

Here are some simple examples:

- Forged parts: Crankshafts, spanners, hammers, gears, aircraft brackets

- Cast parts: Engine blocks, pump covers, valve housings, decorative parts

When you need strength, choose forged. When you need complex shapes, casting is usually the way to go.

Why You Should Trust Huasuma Support for Your Metal Parts?

If you need strong and high-quality metal parts, Huasuma is a smart choice. This company is based in China but works with customers all around the world. Many big industries, like car makers, oil and gas companies, and even airplane builders, trust Huasuma because of their experience and skills.

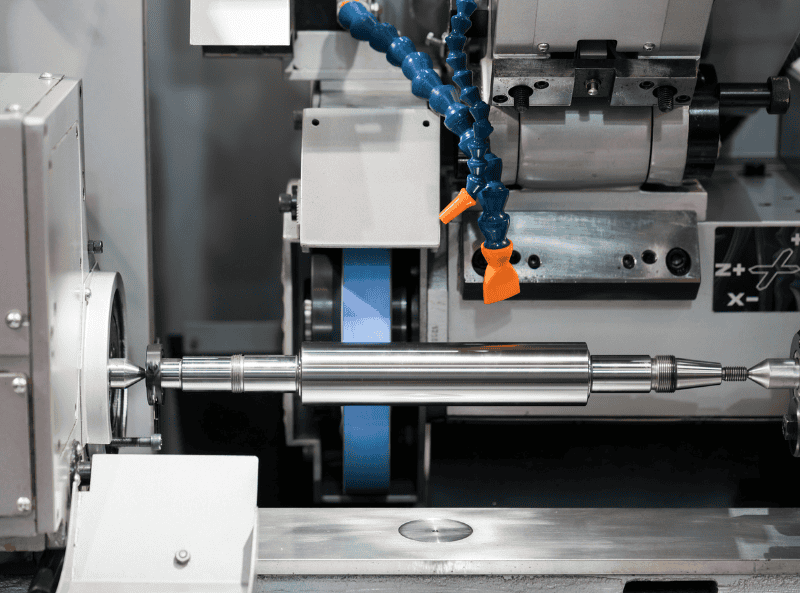

Huasuma can make metal parts using different methods, such as forging, casting, and CNC machining. They handle everything in one place, from choosing the right metal to checking the finished part for quality. This means you get better control, faster service, and parts you can trust.

Why choose Huasuma?

- They do it all: forging, casting, machining, and coating.

- Their parts meet top safety and quality rules in Europe, the USA, and Japan.

- You can ask for help or a price quote any time, 24/7.

- If a part breaks under normal use, they’ll replace it for free.

Conclusion

Now you know the key differences between forging and foundry (casting).

If your part needs to be strong, safe, and long-lasting, forging is the better choice. But if you’re looking for complex shapes or lower costs for small batches, casting may work best for you.

Both methods have their place in manufacturing, and the right choice depends on what your part needs to do.

Take a moment to think about your project’s shape, strength needs, and budget. That will help you pick the process that makes the most sense.

If your next project demands durability, precision, and cost-effective production, you can trust Huasuma to deliver parts that perform.

Visit huasuma.com to learn more or request a free consultation for your custom metal needs.