Cars have many metal parts, and casting helps shape them. This process is used to make things like engine blocks, wheels, and gear cases. It helps build cars that are strong, light, and not too expensive.

Today, cars need to be tough but also light. That’s why casting is so useful. It allows car makers to use metals like aluminum and magnesium. These metals are strong but not heavy.

In this article, you’ll learn what casting is and how it helps make car parts. You’ll also find out how die casting works, what new machines are used, and what changes are coming in the future.

What is Auto Parts Casting?

Auto parts casting is a way to make metal vehicle parts by pouring melted metal into a mold. When the metal cools, it hardens into the shape of the mold. This lets manufacturers create parts that are strong, detailed, and ready to use.

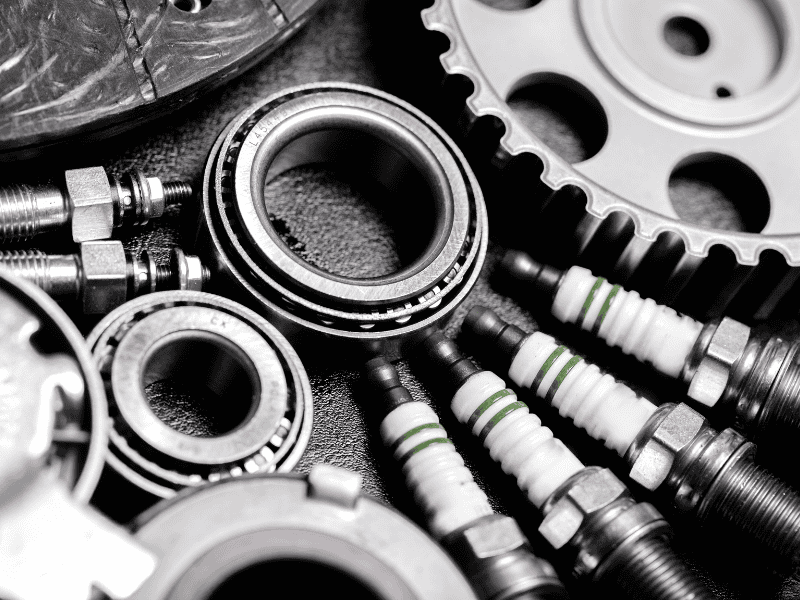

You’ll find cast parts in almost every vehicle. Common examples include:

- Engine blocks

- Cylinder heads

- Transmission housings

- Wheels

- Brake parts

- Mounting brackets

These parts must handle heat, pressure, and wear every day. Metal casting makes sure they can.

What Materials Are Used?

The most common metals in automotive casting are:

- Aluminum alloys – lightweight and great at handling heat

- Magnesium – even lighter than aluminum, used for thin parts

- Cast iron – strong and heat-resistant, often used in engines

- Zinc – good for small parts that need to be precise

Die Casting in Automotive Manufacturing

Aluminum is another popular metal used in manufacturing automobile parts. It is lightweight and has excellent dimensional stability, making them top choices for thin-walled machine parts. Generally, low-density aluminum is more extensively used in the automotive industry. Automotive castings from this metal have higher strength even at high temperatures.

The aluminum die casting process can employ a steel mold to produce thousands of castings in one session. It is ideal for making parts such as engine brackets, gearbox cases, valve bodies, hydraulic cylinders, etc.

Why Choose Die Casting?

Compared to other manufacturing processes, die casting has many advantages:

- It creates parts with exact shapes and sizes.

- You can make many parts quickly.

- Each part is nearly the same, which helps with quality.

- It works well for complex designs.

Because of these benefits, die casting is often used for automotive components that need tight fits and smooth finishes.

Common Die Casting Alloys

Car makers often use:

- Aluminum die casting – for light, strong parts like engine housings

- Magnesium die casting – lighter than aluminum, good for smaller parts

- Zinc die casting – used for precision parts like sensor housings or connectors

These metals help reduce vehicle weight while keeping mechanical properties strong.

Where Is Die Casting Used in Cars?

You’ll find die-cast parts in many places:

- Engine parts

- Cylinder heads

- Body parts like doors and frames

- Suspension components

- Electric vehicle components, such as battery cases and cooling plates

As more electric vehicles hit the road, the demand for lightweight, die-cast vehicle parts is growing fast.

Automotive Casting Process Development

Making car parts with casting has changed a lot over time. In the past, most of the work was manual. Now, factories use smart machines, software, and sensors to make casting better and faster.

Better Tools, Better Parts

Today’s casting starts with computers. Engineers use 3D models to design automotive components. They run simulations to test how the metal will flow into the mold. This helps spot problems before making anything.

Some factories even use digital twins—a computer version of the real casting process. This lets them test and improve the setup without wasting metal.

These tools save time and reduce mistakes. They also help lower production costs.

How Quality Is Checked

Good casting needs good checks. Modern foundries use:

- X-ray machines to look inside parts

- Sensors to track temperature and pressure

- ISO 9001 and IATF 16949 standards to keep quality high

One large auto maker used software to improve its engine block casting line. By changing the mold design and using pressure sensors, they cut defects by 30%. They also made parts faster with less waste.

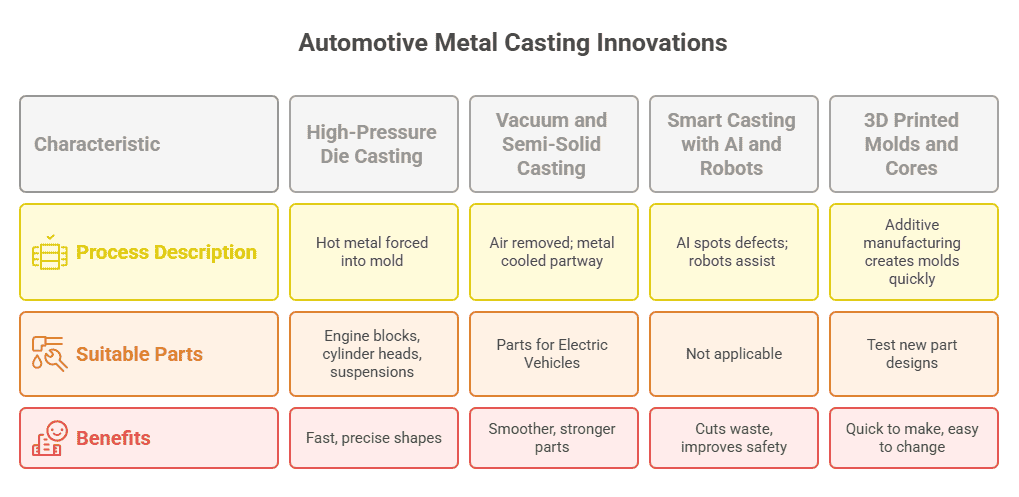

Innovations in Automotive Metal Casting

Car factories now use new tools and smart systems to make casting better. These updates help build lighter, stronger, and cleaner automotive parts faster than before.

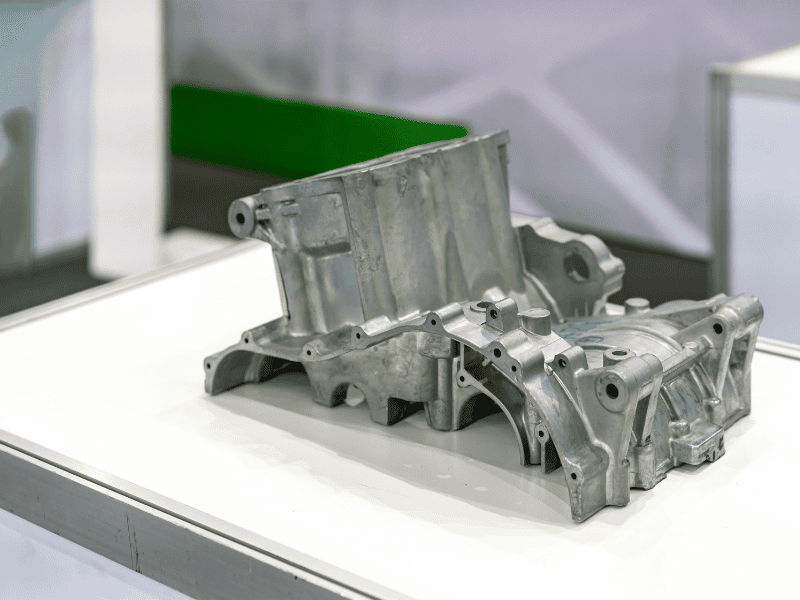

High-Pressure Die Casting (HPDC)

Many car makers use high-pressure die casting to shape metals like aluminum and magnesium. This method pushes hot metal into a mold with great force. It works fast and makes very precise shapes.

HPDC is used for parts like:

- Engine blocks

- Cylinder heads

- Suspension components

These parts must be strong but also light.

Vacuum and Semi-Solid Casting

In vacuum die casting, the air is removed from the mold. This stops bubbles and makes smoother, stronger parts. Semi-solid casting cools the metal partway before casting. This gives better control and less shrinkage.

These methods help when making parts for Electric Vehicles, where safety and strength matter a lot.

Smart Casting with AI and Robots

Factories now use Artificial Intelligence (AI) to spot casting defects. AI tools scan parts and catch tiny cracks or gaps. This cuts waste and improves safety.

Robots also help. They pour metal, move molds, and check heat levels. This saves time and solves the skilled labor shortage.

3D Printed Molds and Cores

Some makers use additive manufacturing (also called 3D printing) to create molds. These printed molds are quick to make and easy to change. This helps test new part designs without high costs.

Trends in the Automotive Casting Industry

The car industry is changing quickly. Casting companies need to keep up. New trends focus on lighter car parts, clean energy, and smarter ways to build.

Making Cars Lighter

One effective strategy is to develop and implement lightweight yet high-performance materials as alternative solutions for conventional automotive materials such as cast iron and steel. Cars now use more aluminum and magnesium instead of heavy steel. These lighter metals help gas cars save fuel. They also help electric cars go farther on one charge. Many parts like engines, gearboxes, and body panels are now made with light metals.

Helping the Environment

Factories are trying to make less waste and use less energy. They melt and reuse old metal parts. They also use furnaces that don’t burn as much fuel. This helps the planet and follows new rules about pollution.

A lot of casting is now done in Asia because more people there are buying cars. But some factories in places like the U.S. and Europe are moving work back home. This helps them save on shipping and control the quality better.

Electric cars don’t have as many moving parts as gas cars. But they do need special parts like:

- Battery covers

- Cooling plates

- Sensor cases

- Lidar holders

Alt Text:

“Worker checking auto parts inventory in a warehouse with organized bins.”

Challenges and New Ideas in Auto Casting

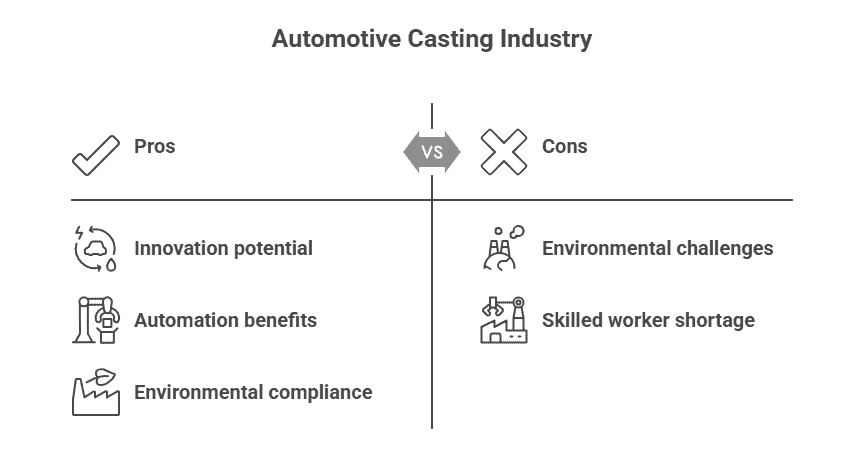

The auto casting industry is growing. But there are still some problems. At the same time, new tools and ideas are making things better.

Governments want factories to be cleaner. They tell casting companies to make less pollution, recycle more, and save energy. This means factories have to change how they work and use cleaner ways to make parts.

Many factories can’t find enough trained workers. Casting is tough and needs special skills. To help with this, factories are now using more machines and robots. These machines work faster and make fewer mistakes. So, even with fewer people, the work stays good.

There are big chances to make things better. New casting metals can make parts that are lighter and stronger. Some factories use computers and sensors to control each step, like making the mold and pouring the metal.

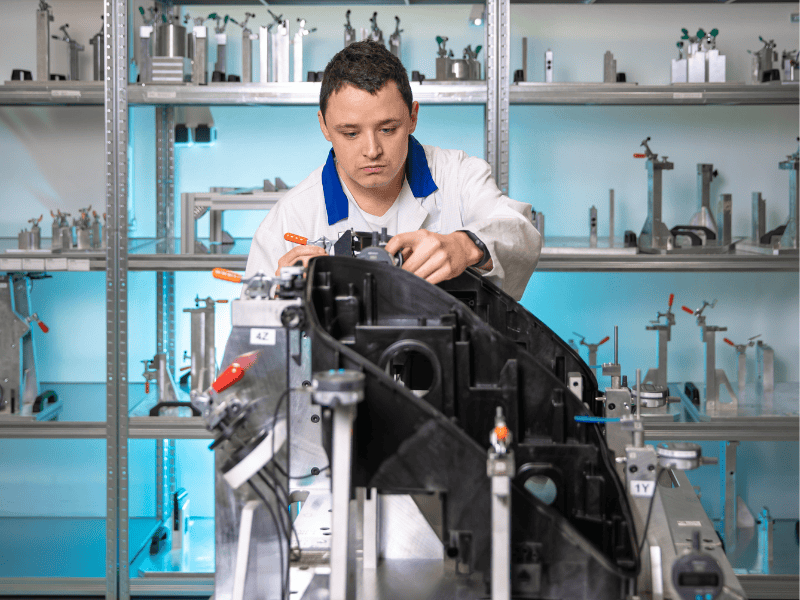

How Modern Foundries Like Huasuma Improve Part Quality

Some factories use old tools. Others, like Huasuma, use new smart tools. They mix machines and computers to make car parts faster and better.

Huasuma uses CNC machines to cut parts with great care. They also use special scanners to check if each part is the right shape and size. These tools help stop mistakes before the parts go to the car company.

They make things like engine blocks, gear covers, and metal brackets. They also use strong but light metals like aluminum and magnesium.

Conclusion

Auto parts casting is very important in making today’s cars. It helps create strong and light parts without spending too much. You learned how die casting, digital twins, and smart tools like AI are making factory work faster and better.

Car makers now want lighter, cleaner, and smarter parts, especially for electric vehicles. The future looks good for casting. But factories must keep using better tools, smart ideas, and clean systems to stay strong and keep up with new car needs.

Want to stay ahead? Now is a good time to explore new casting solutions or improve your current process. If you’re looking for expert help, reach out to learn how modern casting can support your business.