In modern manufacturing, industrial casting methods play a vital role in shaping the backbone of industries from aerospace to automotive. Each casting technique offers distinct advantages in material use, design precision, cost, and production scale. If you are involved in auto parts casting, product design, or automotive casting process development, understanding these methods is crucial.

In this article, I will break down the top 12 industrial casting methods and their applications, advantages, and why they matter in the evolving world of automotive metal casting.

What Is Industrial Casting?

Industrial casting refers to the process of shaping metal parts by pouring molten metal into molds specifically designed for use in industrial applications. This method allows for the production of complex and durable components that are critical in sectors like automotive, aerospace, construction, and heavy machinery.

Often referred to as metal casting for industry, this process ensures high-volume, high-strength production of parts with consistent quality and performance.

How It Differs from General Casting:

While general casting can refer to any casting method (including artistic, decorative, or small-scale uses), industrial casting is defined by:

- Built for function, not decoration

- Focused on high volume and durability

- Requires tight quality control

- Uses advanced machines and materials

A Closer Look at the Most Common Industrial Casting Methods

Now that we’ve explored what industrial casting is and how it differs from general casting, let’s dive into the 12 key casting techniques that power today’s manufacturing, mainly in the auto parts casting and automotive metal casting industries. Each method offers unique advantages in terms of cost-efficiency, precision, material compatibility, and production scale.

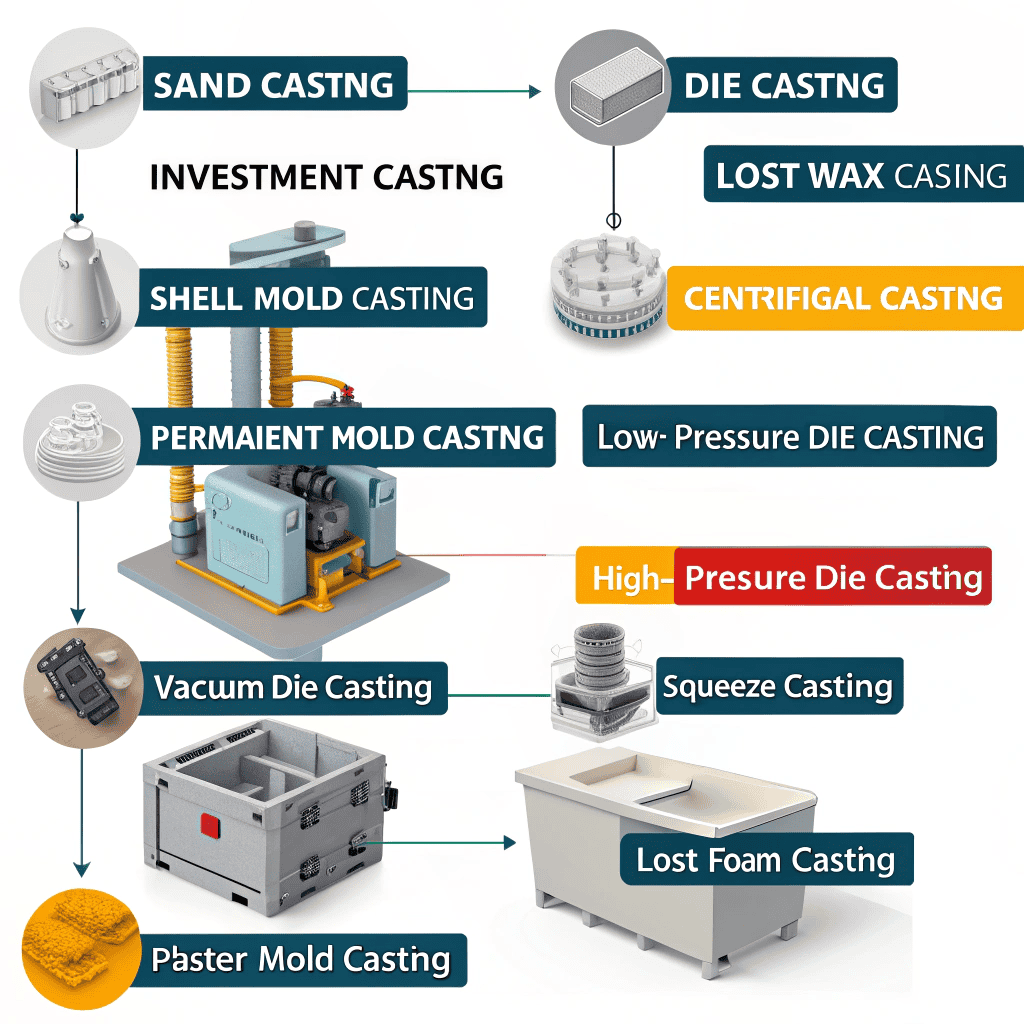

1. Sand Casting

The term “Sand Casting” can be used to describe the final product and the process to make it. One of the oldest and most versatile industrial casting methods, sand casting uses sand-based molds to shape molten metal. It remains essential in auto parts casting, especially for large components like engine blocks, exhaust manifolds, and brackets.

- Used for: Engine blocks, manifolds, heavy auto components

- Pros: Low cost, reusable materials, handles large parts

- Cons: Rough surface finish, limited precision

Despite lower precision than die casting, sand casting remains vital in automotive casting process development for its adaptability and cost-effectiveness. As trends in the automotive casting industry push for durability and sustainability, this method stays relevant. Mostly when paired with innovations in automotive metal casting, like enhanced sand blends and digital mold design.

2. Die Casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. Common in auto parts casting, it’s ideal for components like gearboxes, brackets, and transmission housings.

- Used for: Gearboxes, brackets, transmission housings

- Pros: High dimensional accuracy, great for high-volume production

- Cons: Higher cost, limited to non-ferrous metals

As a key part of automotive casting process development, die casting supports mass production with excellent detail. Current trends in the automotive casting industry show a rise in die-cast aluminum, especially for EVs. Innovations in automotive metal casting, such as vacuum-assisted systems, are also enhancing its performance.

3. Investment Casting (Lost Wax Casting)

Ideal for high-precision and intricate components, this method uses wax patterns and ceramic molds. This technique plays a vital role in auto spare parts casting, especially when complex geometries and tight tolerances are required.

- Used for: Turbocharger parts, fuel system components

- Pros: Excellent detail, great surface finish

- Cons: Higher cost, longer production time

Innovations in Automotive Metal Casting: Investment casting is advancing with 3D-printed wax patterns, contributing significantly to automotive casting process development and aligning with recent trends in the automotive casting industry.

4. Shell Molding

A variant of sand casting, shell molding uses a resin-covered sand that hardens into a shell-like mold. It’s especially useful in auto parts casting where consistency and surface quality are important. Shell molding was originally referred to as the Croning process after Johannes Croning. He patented the process in Germany in 1943. Later, the process became known as “shell mold casting” or simply “shell molding.”

- Used for: Camshaft, connecting rods, brake parts

- Pros: Better finish than regular sand casting, good repeatability

- Cons: Higher mold cost

As part of evolving automotive casting process development, shell molding supports precise manufacturing needs and reflects key trends in the automotive casting industry, especially for high-stress components.

5. Centrifugal Casting

This process involves pouring molten metal into a rapidly spinning mold, allowing centrifugal force to distribute the metal evenly. It’s widely used in auto parts casting for components that experience high rotational forces.

- Used for: Cylinder liners, clutch rings, flywheels

- Pros: High strength, fine-grained outer structure

- Cons: Limited to round or symmetrical parts

As part of ongoing automotive casting process development, centrifugal casting plays a vital role in producing durable, high-performance parts. With recent innovations in automotive metal casting, this method supports precision in components subjected to continuous motion, highlighting key trends in the automotive casting industry, especially in performance-driven vehicle systems.

6. Permanent Mold Casting

In this process, molten metal is poured into durable, reusable metal molds, typically using gravity or low pressure. It’s commonly applied in auto parts casting where uniformity and surface quality are essential.

- Used for: Pistons, intake manifolds, brake calipers

- Pros: Good surface finish, repeatable results

- Cons: Less flexible than sand casting for complex shapes

As part of modern automotive casting process development, permanent mold casting balances cost-efficiency with quality. With ongoing innovations in automotive metal casting, it supports trends in the automotive casting industry focused on precision and lightweight parts. While similar to die casting, it is typically used with different alloys and suits medium-volume production.

7. Low-Pressure Die Casting

Low pressure die casting is a method of production that uses pressure – rather than gravity – to fill molds with molten metal such as aluminum and magnesium. Molten metal is pushed into the mold from below using low-pressure air, allowing slow, controlled filling. Ideal for high-integrity auto parts casting.

- Used for: Alloy wheels, structural components

Pros: Minimal porosity, better mechanical properties

Cons: Slower production

Part of modern automotive casting process development, this method aligns with key trends in the automotive casting industry, offering improved quality for lightweight parts. It also complements die casting through better control and reduced defects.

8. High-Pressure Die Casting

This fast, high-pressure method is ideal for mass auto parts casting, pushing molten metal into molds at high speed for rapid production.

- Used for: Engine mounts, steering components, transmission cases

- Pros: Fast, cost-effective for large runs

- Cons: Higher tooling cost, more porosity

A key part of automotive casting process development, it supports major trends in the automotive casting industry. Thanks to recent innovations in automotive metal casting, it’s now used for large components like Tesla’s Giga Castings. They blend scale with precision in modern die casting.

9. Vacuum Die Casting

In this process, air is removed from the mold before metal injection, reducing porosity and defects, ideal for high-strength auto parts casting.

- Used for: Structural parts requiring superior strength

- Pros: Enhanced mechanical properties

- Cons: Specialized equipment required

As part of evolving automotive casting process development, vacuum die casting offers superior quality for critical components. With ongoing innovations in automotive metal casting, it reflects rising trends in the automotive casting industry, especially for safety and performance-driven applications beyond standard die casting.

10. Squeeze Casting

This hybrid process combines casting and forging. Molten metal is poured into a die and squeezed under pressure before solidifying, making it ideal for high-stress auto parts casting.

- Used for: Suspension components, steering knuckles

- Pros: Excellent strength, minimal defects

- Cons: Slower and costlier than other casting methods

A rising method in automotive casting process development, squeeze casting delivers strong, defect-free parts. With current innovations in automotive metal casting, it’s gaining traction especially in EV and hybrid production, highlighting major trends in the automotive casting industry beyond traditional die casting.

11. Lost Foam Casting

This process uses polystyrene foam patterns that vaporize when molten metal is poured in, ideal for complex auto parts casting.

- Used for: Engine blocks, crankshafts

- Pros: Simplifies mold-making, suitable for complex parts

- Cons: Foam pattern production can be tricky

As part of modern automotive casting process development, lost foam casting enables intricate designs with fewer steps. With ongoing innovations in automotive metal casting, it’s increasingly used for high-precision applications, aligning with current trends in the automotive casting industry focused on efficiency and design flexibility beyond conventional die casting.

12. Plaster Mold Casting

This method uses plaster instead of sand, allowing for finer detail and smoother finishes. This casting is ideal for low-volume auto parts casting and prototypes.

- Used for: Prototypes, thin-walled aluminum components

- Pros: High detail and finish

- Cons: Not suitable for high temperatures or steel

Within automotive casting process development, plaster mold casting supports design testing and lightweight part production. As innovations in automotive metal casting expand, this technique aligns with trends in the automotive casting industry that prioritize precision, especially in early-stage development. Though not used in standard die casting, it’s valuable in specialized applications.

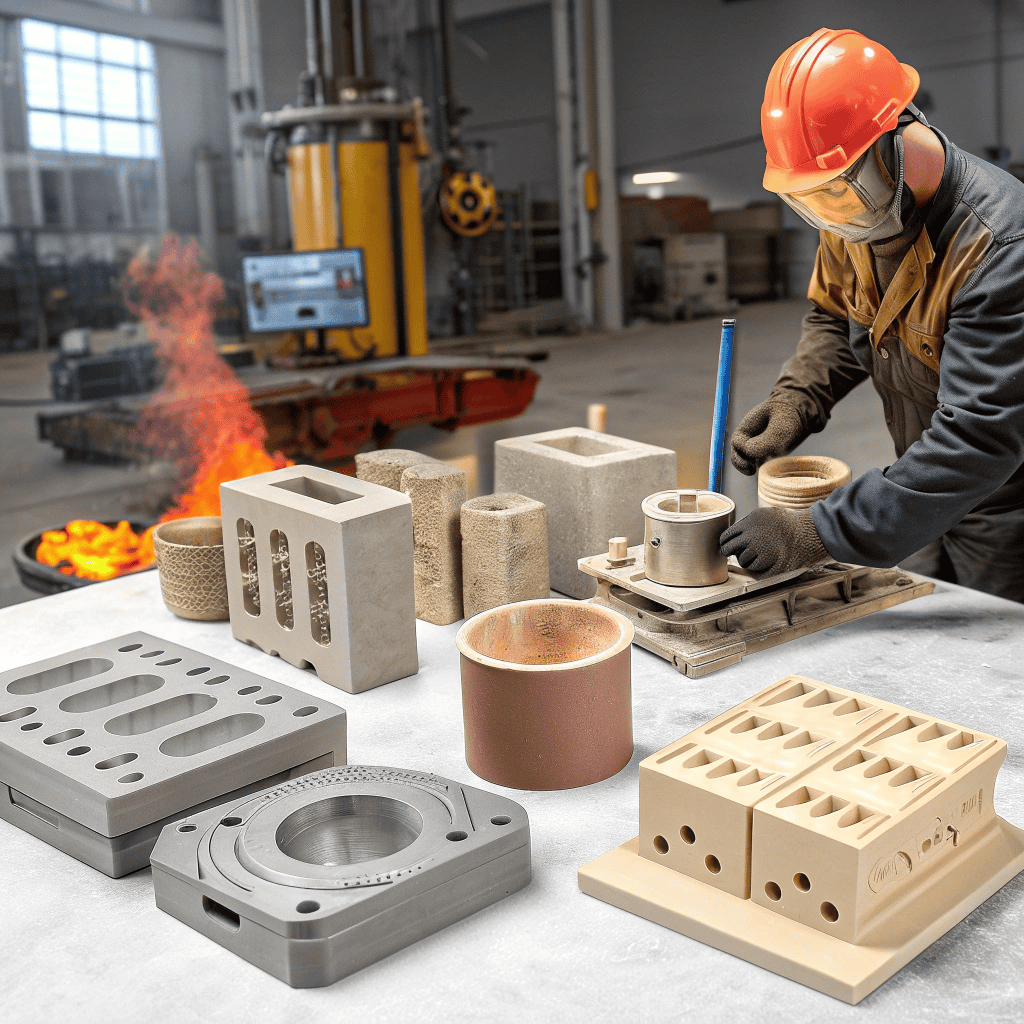

The Basic Steps in Industrial Casting

1. Pattern Making

The process starts with making a pattern, a model of the final part. Patterns are often made using CAD software to be accurate. They are designed to allow for metal shrinkage during cooling.

2. Mold Making

Next, a mold is created to hold the metal. There are two main types: reusable and one-time use (expendable).

- Sand molds are common and made by shaping sand inside a frame.

- Plaster and ceramic molds are made by pouring liquid material around a wax model, which is later removed.

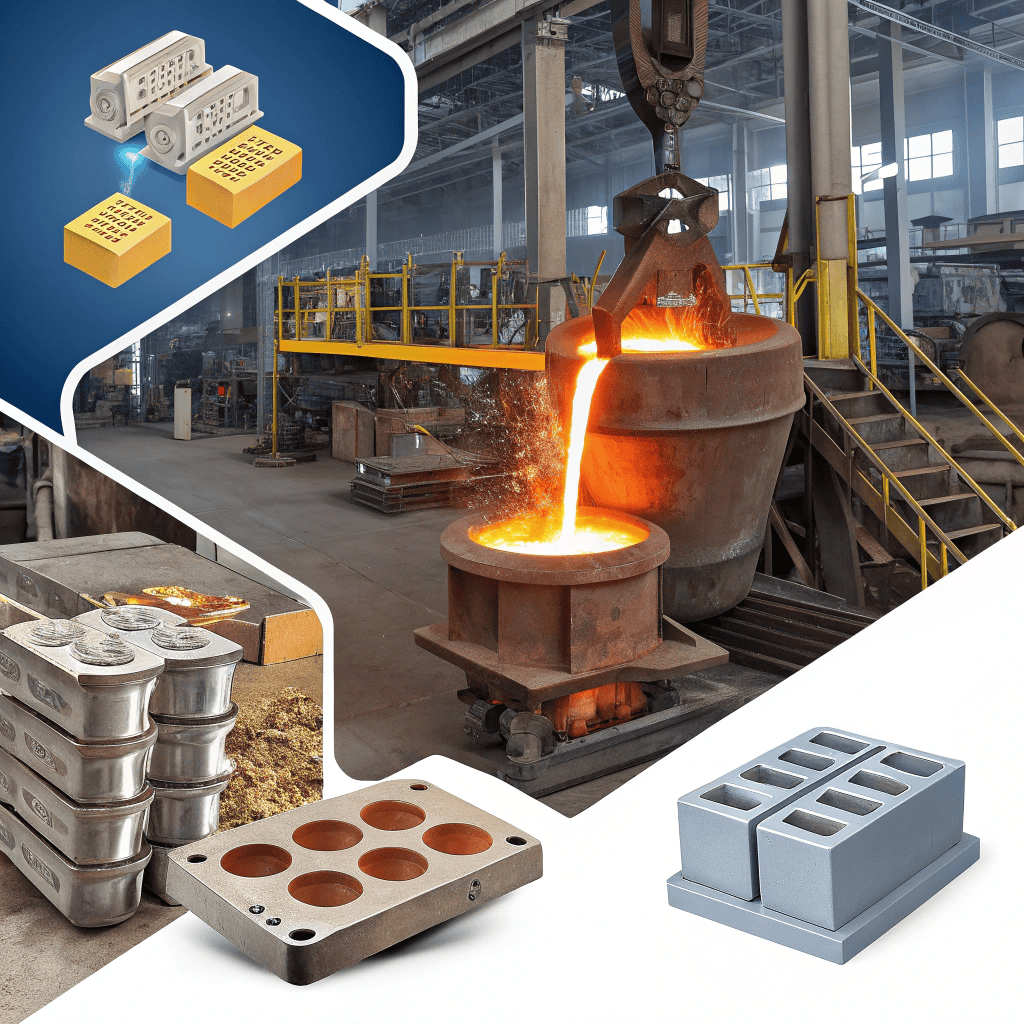

3. Melting and Pouring Metal

Metal is melted in a furnace or crucible until it becomes liquid. Then it is poured into the mold. Safety is important, that’s why workers always wear protective gear and follow safety steps. After pouring, the metal cools and hardens in the mold.

4. Removing the Casting

Once cooled, the mold is broken or opened and the solid metal part is taken out.

5. Finishing

The final part is cleaned and smoothed. This may include removing extra metal, scrubbing, polishing, or machining. Finishing can also involve coating or heat treatment to improve the quality.

Materials Used in Industrial Casting

Industrial casting uses both ferrous (iron-based) and nonferrous (non-iron) metals depending on the part’s needs. Here are list of materials that are used in industrial castings:

- Common metals include steel, stainless steel, aluminum, copper, magnesium, and zinc.

- Ferrous alloys like steel, gray iron, and malleable iron are strong and used for many heavy-duty parts.

- Nonferrous alloys like aluminum, brass, and bronze are lightweight, resist rust, and are great for detailed or outdoor parts.

Some special materials include:

- Manganese steel: gets stronger with use, good for heavy machinery.

- Nickel-based alloys: excellent for chemical and high-corrosion environments.

- Heat-resistant stainless steel: used at high temperatures (over 1200°F).

- New alloys and composites: offer better strength while keeping parts lightweight.

Vacuum casting is often used with these materials to reduce gas bubbles and improve quality. Choosing the right material helps prevent problems like shrinkage and porosity, ensuring the part is both strong and reliable.

Advantages of Industrial Casting

- Cost-effective for complex shapes with minimal material waste

- Scalable for both small and large parts

- Lightweight & strong designs, like magnesium casings for tech and medical devices

- High precision with methods like investment and lost-foam casting

- Uniform structure from techniques like centrifugal casting

- Fewer defects and better integrity with squeeze casting

- Eco-friendly metals can be recycled and reused

- Reduced finishing time, saving on production costs

Challenges in Industrial Casting

Industrial casting, particularly in auto parts casting, faces several challenges such as porosity, shrinkage, warping, and fusion. These defects can compromise the structural integrity of cast components. To overcome them, manufacturers implement better cooling systems, utilize stronger mold materials, and redesign molds to reduce misalignment and flow issues. Advanced die casting techniques are also being adopted to minimize gas entrapment and solidification flaws.

Future Trends in Automotive Casting Industry

The automotive casting process development is undergoing a major transformation driven by Industry 4.0. Real time monitoring using IoT sensors, automation via robotics, and digital twin simulations are streamlining casting workflows, improving efficiency, and reducing waste. Additionally, innovations in automotive metal casting focus on sustainability, reducing energy usage, recycling metal scraps, and using eco-friendly mold materials. These advancements are not only improving casting quality but also reshaping operational models across the automotive casting industry.

Choosing the Right Casting Method for Your Needs

Selecting the right casting method depends on several factors: component complexity, material requirements, production volume, and cost-efficiency. For intricate or lightweight components, such as those in the automotive sector, die casting is often preferred due to its precision and consistency. Evaluating a suppliers’ experience in auto parts casting, their process range, and adherence to industry certifications is crucial. Also, partners with in-house machining and design services can offer faster turnaround and better integration from prototype to final part.

Outsourcing Industrial Casting Services

Outsourcing automotive casting process development to specialized providers enables access to advanced technologies, cost savings, and expert guidance. Companies like RapidDirect offer quick online quotations, material recommendations, and professional engineering support, making them ideal for handling both prototype and production-scale projects. This approach allows manufacturers to focus on core innovation while ensuring high-quality casting outcomes.

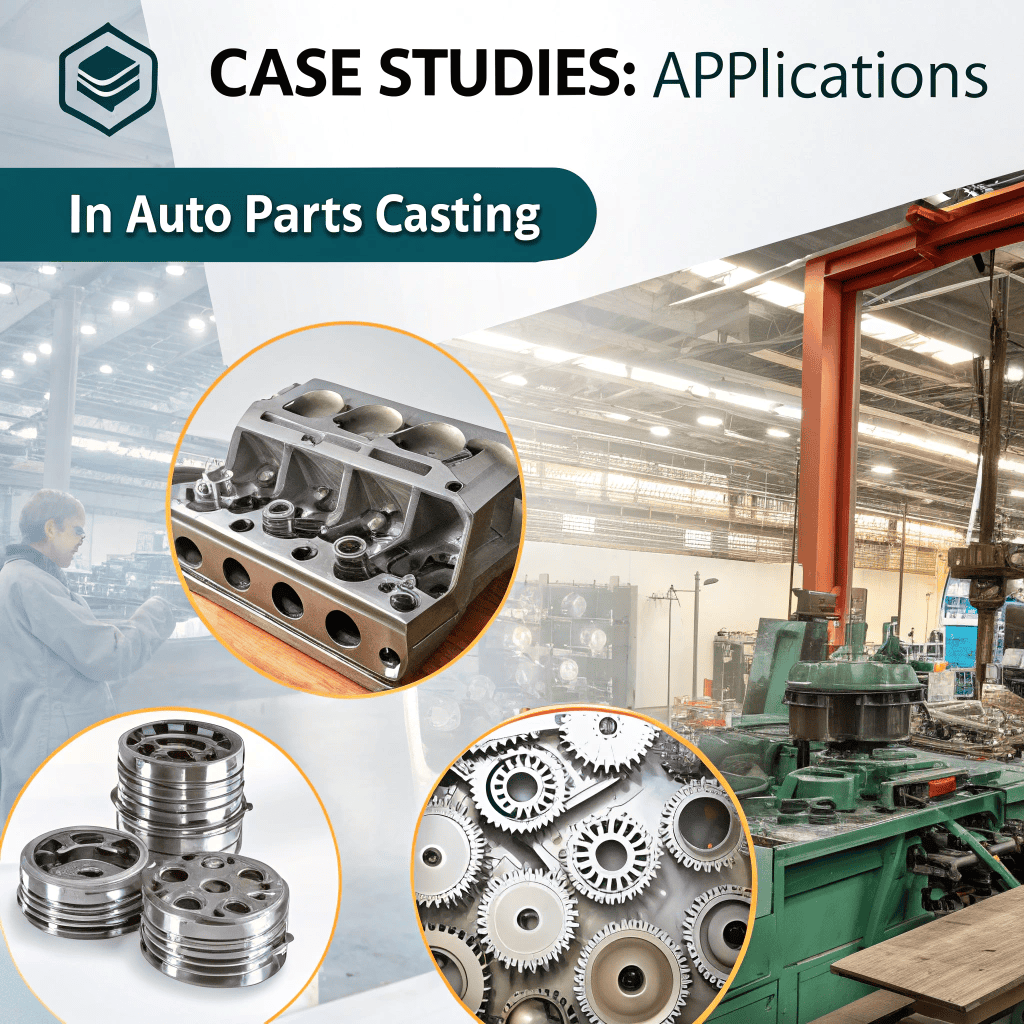

Case Studies: Applications in Auto Parts Casting

Successful applications of industrial casting in the automotive field highlight its flexibility and performance benefits. For instance, Kodak and Nikon developed a professional digital camera body using magnesium die casting, showcasing the potential of this method in lightweight yet durable product designs. In another example, a die cast aluminum component was used in an award-winning archery bow, demonstrating high precision and strength.

Automotive parts such as GPS enclosures, laser housing units, and vaporizer regulators have also leveraged advanced casting methods to achieve rugged, functional, and efficient designs.

Many auto manufacturers are turning to die casting to improve both quality and speed.

For example, Tesla’s Model Y rear underbody was reduced from 70 welded parts to a single die‑cast structure, cutting weight by ~30% and costs by ~40%.

Similarly, BYD has heavily increased the use of aluminum alloy die‑cast parts in its electric vehicle platforms, up to 62% in structural components like battery trays and underbody panels, demonstrating a shift toward integrated casting in its vehicle designs

These real-life examples show how auto parts casting, innovations in automotive metal casting, and modern trends in the automotive casting industry are helping China become a global leader in smarter, lighter vehicles.

Selecting the Right Casting Partner

When choosing a partner for auto parts casting, consider their capabilities across several key areas:

- Proven expertise in die casting and process customization

- Strong quality control systems

- Experience in handling a range of alloys and part geometries

- Certifications relevant to automotive and industrial standards

- Ability to offer metallurgy support, design optimization, and quick lead times

Visiting a supplier’s facility and reviewing pasvt projects can also offer insights into their capacity and reliability.

Final Words

Each casting method serves different needs in industrial and automotive manufacturing. With increasing demand for lightweight, durable, and precision parts, companies must stay updated on the latest trends in the automotive casting industry and adopt the right techniques for efficiency and innovation.

Whether you’re focusing on auto parts casting, developing new casting processes, or exploring innovations in automotive metal casting, understanding these 12 methods gives you a strong foundation to make better production decisions.

For reliable, high-quality auto parts casting, contact Hanke Construction Machinery Manufacturing Co., Ltd.. With advanced equipment, strict quality control, and experience serving major clients like XCMG Group, Hanke is a trusted name in modern casting solutions.