Cold forging is a way to shape metal without heating it up. The metal is pressed into a mold (called a die). This makes the metal stronger and smoother. It is used to make parts like bolts, fasteners, and car parts. Cold forging is quick, accurate, and makes many parts that are all the same.

Cold forging is important because it makes strong parts that last a long time. It doesn’t use a lot of material or energy. Since no heat is needed, it is also cheaper and better for the environment. It’s used to make parts for cars and airplanes, where the parts need to be strong. Cold forging is also fast, so it can make a lot of parts at once, without losing quality.

What is Cold Forging

Cold forging is a manufacturing process that involves shaping metal into a desired form using mechanical pressure. Unlike traditional forging, which involves heating the metal prior to forming, cold forging is done at room temperature.

During the process, the metal is placed into a die and is subjected to a high amount of pressure, which shapes it into the desired form.

The result is a product that is strong, precise, and has a high degree of dimensional accuracy. Cold forging is used in a variety of industries, including automotive, aerospace, and construction, and is particularly effective for producing parts that require exceptional strength and durability.

Given its advantages over other manufacturing techniques, cold forging has become an increasingly popular choice for businesses seeking to create high-quality metal parts at a lower cost.

Definition and basic principles

Cold forging is a process where metal is shaped at room temperature. This means no heating is needed. The metal is pressed with high pressure to squeeze it into a mold, which gives it the right shape.

This process makes the metal stronger and smoother, and there is very little waste. Cold forging is often used in making parts like bolts, screws, and car parts. It’s known for being fast and making parts with a high level of accuracy.

The fundamental principle is inserting a metal blank into a die. Then deforming it under pressure using a punch or a press, compressing the material to flow into the die cavity. This will produce a stiff, accurately sized part.

How it differs from hot forging and warm forging

Cold forging, warm forging, and hot forging are all different. It is because they use different temperatures. This affects how strong the metal becomes, how smooth it looks, and how much energy is needed:

- Cold Forging happens at room temperature. It makes the metal hard and smooth but needs a lot of force because the metal is not soft.

- Warm Forging happens at temperatures between 500°C and 800°C. It needs less force than cold forging. But still makes the metal strong and smooth.

- Hot Forging happens at very high temperatures. It happens above the point where the metal becomes soft. It’s easier to shape the metal, but it may not be as accurate, and the surface can be rough.

The process used depends on the type of product, how many parts are being made, and what the material is.

Common materials used

Cold forging uses metals that are easy to shape without breaking. Some common metals used are:

- Carbon Steel is cheap and strong. It’s used for bolts and car parts.

- Alloy Steel is tough and strong. It lasts a long time and doesn’t wear out easily.

- Stainless Steel is used when you need metal that won’t rust. It’s used in food and medicine items.

- Aluminum doesn’t rust and is used in electronics and airplanes.

- Copper and its alloys are great for electricity. They are used in electrical devices.

These metals are chosen based on how strong, flexible, or rust-resistant they need to be.

Cold Forging Operations

Cold forging incorporates upsetting, extrusion, and coining. This is where metal is shaped at room temperature. These operations generate tough, accurate pieces with less wastage. Let us have a look at how every cold forging process is conducted:

Blanking

Wire or metal sheet is struck into precise shapes, lengths, or blanks. These blanks are used as raw material to be shaped.

Forward Extrusion

Metal is pushed into a die. Pressure closes the metal through a small opening, elongating it and making it thinner.

Backward Extrusion

The punch is pushed into the blank, and the die stops the punch from going further. This squeezes the metal to travel reversely, filling a restricted space around the punch.

Upsetting

The metal is driven on both sides, expanding and growing thick in diameter. The process is usually utilized to manufacture heads for bolts or fasteners.

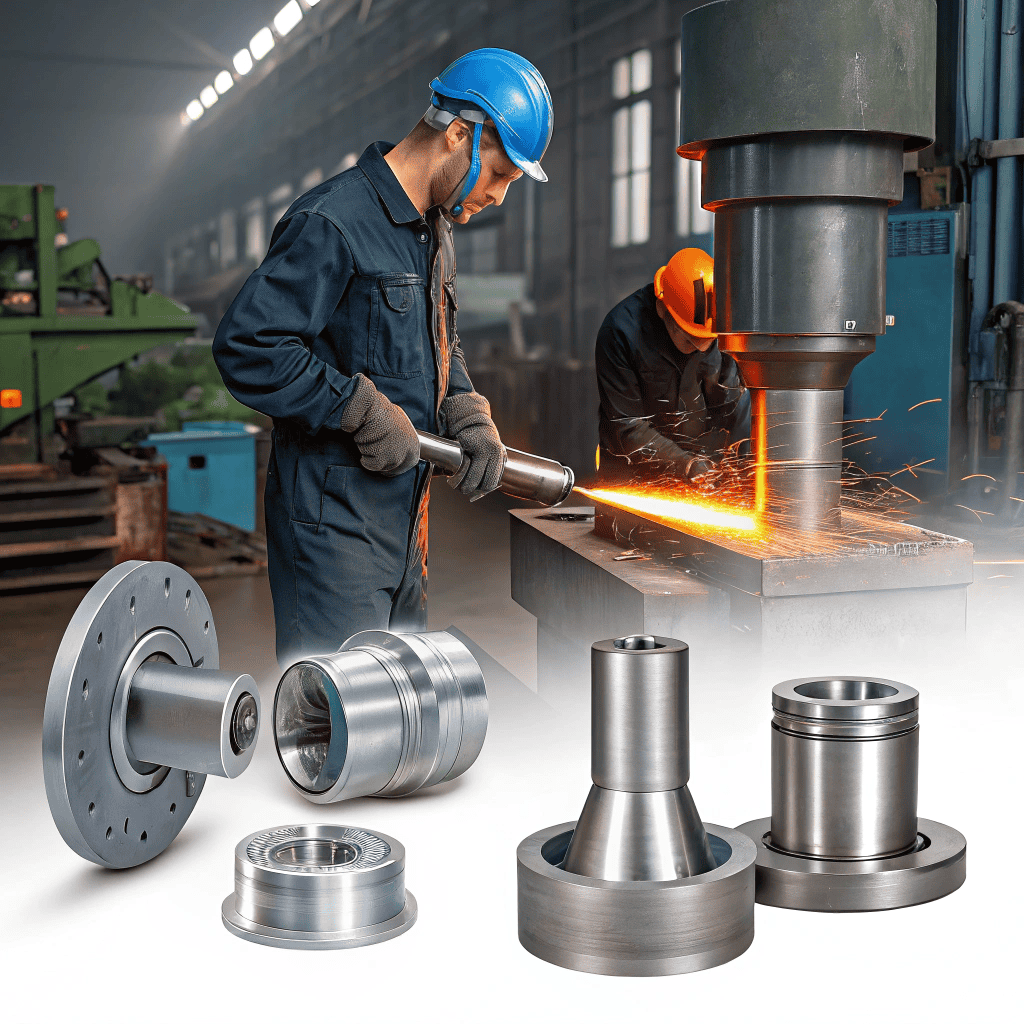

Examples of typical components produced

Some of the parts commonly made by cold forging include:

- Bolts and screws: utilized in cars, construction, and equipment.

- Nuts and rivets: used in construction and machinery applications.

- Axles and shafts: utilized in machinery and vehicles.

- Gear blanks: the foundation for manufacturing precise gears.

- Pins and fasteners: used in aircraft, electronics, and household appliances.

Low Temperature Forgings: Why It Matters

Low-temperature forging is when the metal is shaped between room and structure to change temperatures. It is a compromise between warm forging and cold forging. It saves energy that would be expended on shaping the metal. But yields a good size tolerance and surface finish.

This process is better than cold forging as the metal is more pliable but not as warm as hot forging. Hence, there is less likelihood of oxidation. It is suitable for metals that are too hard to be cold forged but do not require the high temperature of hot forging.

What “low temperature” really means in forging

It is heating the metal to a temperature between somewhat below room temperature. Also below the temperature at which structure change (recrystallization) occurs. This will typically be between 200°C and 500°C, varying with the metal.

At this temperature:

- The metal is softer than cold forging, so the shape requires less pressure.

- It’s not warm enough to cause the metal to form large grains or oxidize, such as in hot forging.

- It balances hardness and formability, suitable for materials too brittle to be cold-forged.

- It’s not cold, so there is a low temperature in forging. It’s warm enough to form the metal but cold enough to preserve the good properties of the metal.

Impact on material properties

There are various impacts on metal properties. Some are described below:

Increased Flexibility: Metals are ductile at cold temperatures instead of room temperature. They can be molded then without breaking. It is easier to process than cold forging when the metals get hardened.

Increased Strength: The metal gets tougher through how it is molded. The process can also give it extra strength. It is suitable for parts that must be tough and precisely sized.

Less Internal Stress: Cold temperatures have less likelihood of causing internal stress. This might be present in cold forging. This reduces the likelihood of twisting or bending once the metal has been formed.

Improved Surface Finish: Low temperatures prevent the metal from oxidizing. Also from becoming rough on the surface.

Less Tool Wear: Lower-temperature forging requires less tool wear.

Low-Temperature Forging: Why It’s So Beneficial

Low-temperature forging helps in the production of parts that are strong with fewer errors. Also no surface quality or strength loss. It is utilized in various industries to manufacture precise parts with minimal waste.

Use cases across industries

In automotive:

- Parts: Crankshafts, axles, gears, bolts.

- Why: It helps create strong and accurate car parts with less waste.

In aerospace:

- Parts: Turbine blades, aircraft components, landing gear.

- Why: It creates strong but light parts with a smooth surface.

In Electronics:

- Parts: Connectors, pins, housings, terminals.

- Why: It’s used to create small, accurate parts that work well and last long.

Low-temperature forging creates strong, accurate, and long-lasting parts in different industries.

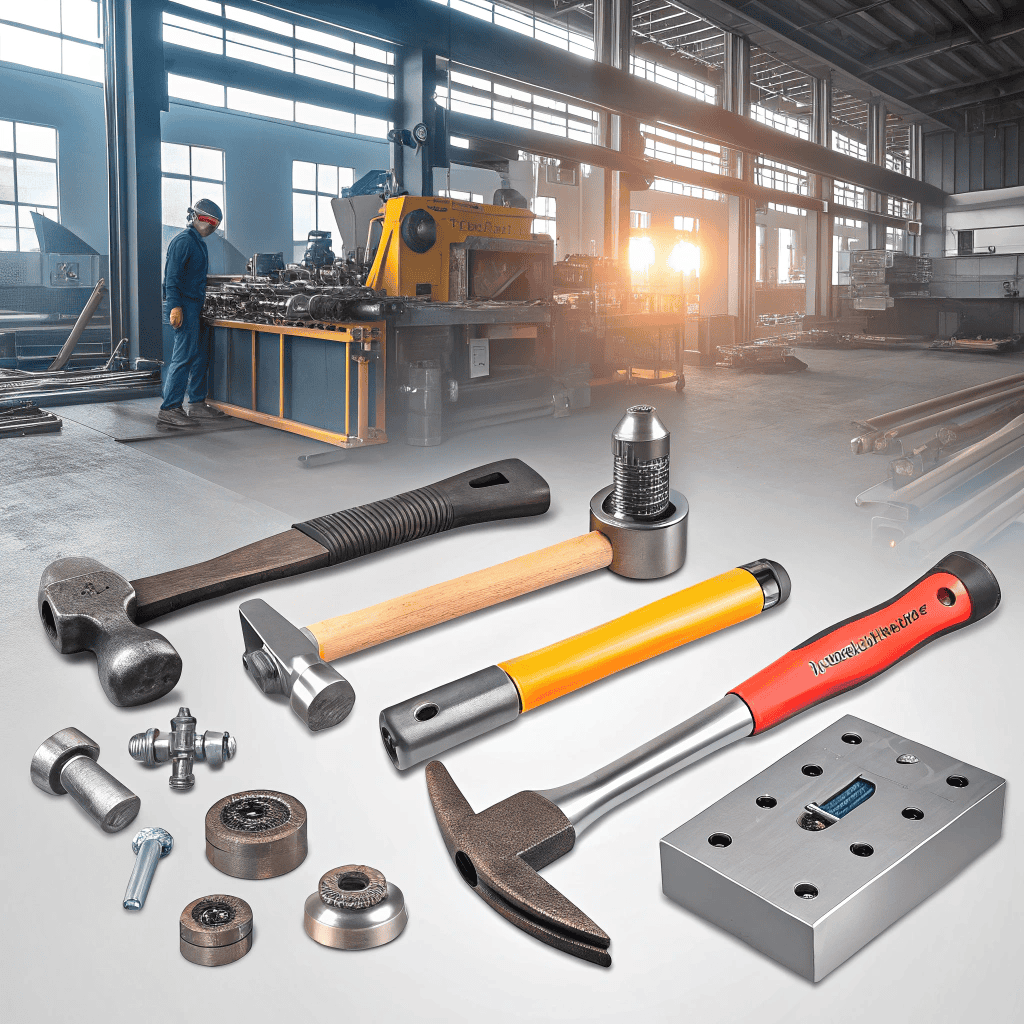

Tools Used in Cold Forging

Cold forging uses equipment like dies, punches, and presses. It is used to shape metal under pressure. Tools are very hard and made to withstand the huge force used in forging.

Description of cold forging tools and dies

Dies: Dies are the basic tools that shape the metal.

There are two types:

Female Die (Cavity Die): The stationary part that shapes the outside of the metal.

Male Die (Punch): The implement that pushes the metal into the female die to shape it.

Dies are made of hard materials, like tool steel, to withstand the pressure of the forging.

Punches: Punches push the metal into the die to shape it. They come in all shapes and sizes depending on what type of forging is being done.

Presses: Presses are equipment that pushes the dies together with tremendous pressure.

They are hydraulic presses or mechanical presses. Presses can be controlled to adjust the speed and pressure used.

Tooling Inserts: Inserts are used on dies to help extend their lifespan and perform better.

They are made of hard materials like tungsten carbide. They are replaced whenever needed to keep the tools in precise shape.

Importance of precision tooling

These tools are hard and precise, so the final product has the right strength, shape, and quality.

Why Good Tools Are Crucial in Cold Forging

Good tools play an important role in cold forging. Proper tools create better parts, and the process is easier. Here’s why:

Right Size and Shape: Proper tools guarantee the proper size and shape of the parts, i.e., fewer defects. This is critical in the automobile and air industry.

Maintains Quality Constant: Rugged equipment does not deteriorate even upon repeated use. They always produce similar quality products . It is with the proper amount of strength and smooth surface.

Less Waste, Less Money: If machinery is accurate, there will be less waste product. That decreases the cost of making the pieces.

Tools Will Last Longer: Good quality tools are built to serve for a long time, so they won’t require repairs or replacement often. That’s cost- and time-saving. Good tools help produce better parts that are tougher, longer-lasting, and smoother.

It is required for parts that have to operate in harsh conditions. Good tools help make better parts, save money, and work better.

Lubricants and surface preparation

Lubricants (oils) and surface finishing are used in cold forging. It is to make the operation smoother. It also increases the life of the tools, and improves the looks and usability of the parts.

Lubricants

Lubricants somewhat lower the workpiece-tool-metal friction, thereby making cold forging easier. They achieve that in several ways:

Reduction of Friction: Lubricants create a thin film between the metal and tools so that the metal glides smoothly into the die. It prevents the metal from adhering and pushing too hard into the tools.

Cooling: Lubricants also serve to cool the metal and tools. Lubricants dissipate the heat produced in forging. Therefore, the metal and tools are not heated and become damaged.

Preventing Oxidation (Rust): Lubricants cause the metal to avoid contact with air. They prevent rust development.

Different lubricants are used in cold forging. They involve oil lubricants, water lubricants, and dry lubricants. The to be used is different depending on the metal in use, the process of forging, and the environment.

Surface Preparation

Surface preparation refers to the cleaning of the metal before forging. It cleans off dirt, rust, and other materials that may lead to problems in forging. It is essential because:

Improved Material Flow: With the metal being smooth and clean, it becomes easier to pour into the die. This avoids cracking or incomplete die-filling, leading to part defects.

Enhanced Tool Life: Removing dust, oil, and rust from the metal prevents tool wear. This ensures the tool life is prolonged and frequent replacement is avoided.

Improved Surface Finish: Cleaning the metal surface makes the part look cleaner and smoother. This helps the part look nice and ensures it works properly when finished.

Using lubricants and conditioning makes the cold forging process smoother. It helps make better parts with fewer problems and less waste.

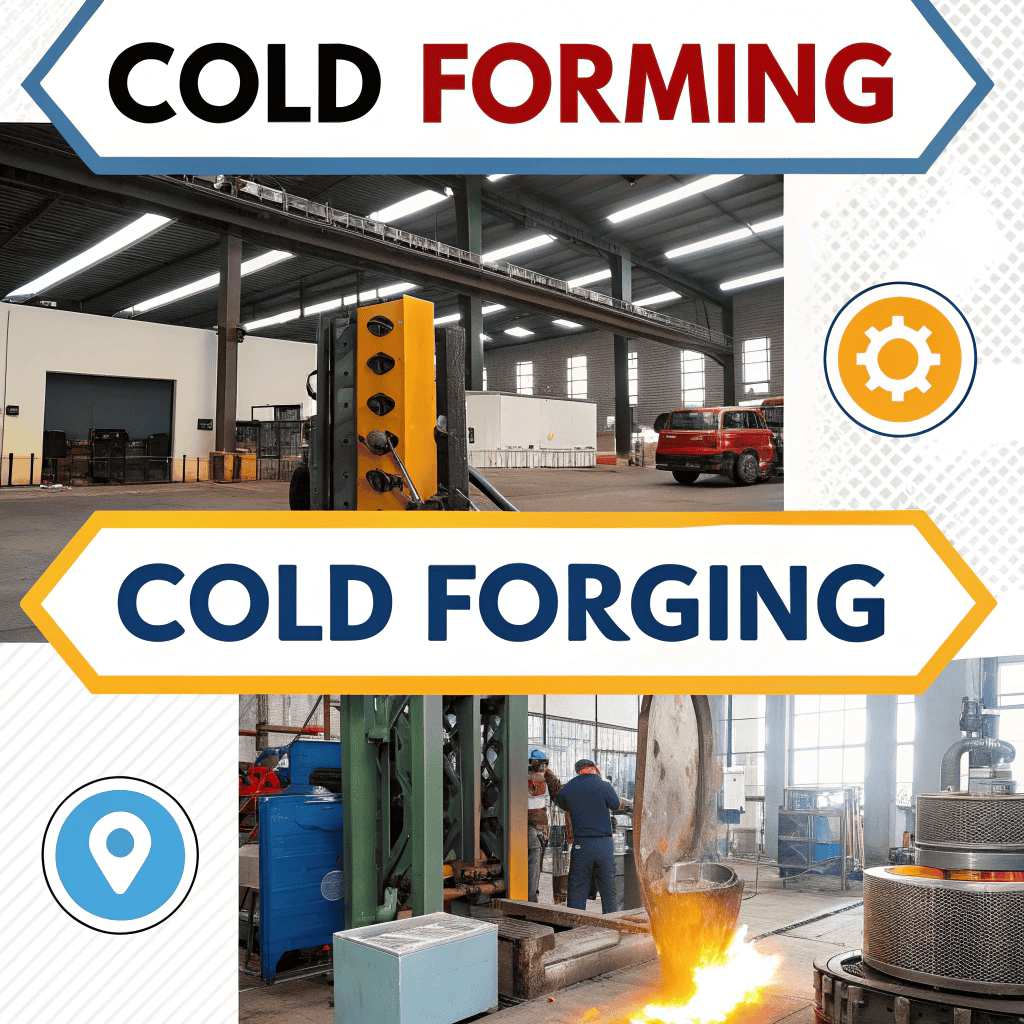

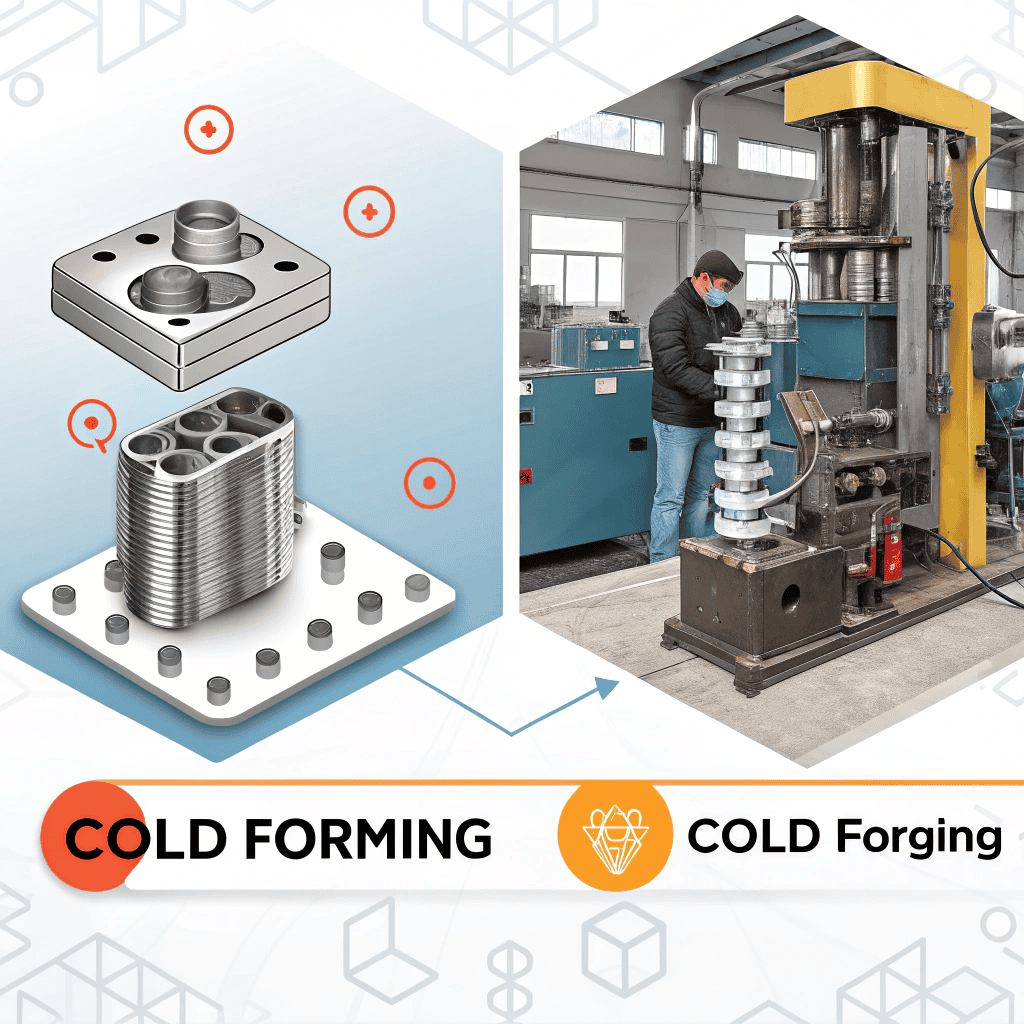

Cold Forming vs. Cold Forging: What’s the Difference?

Cold forming and cold forging are both ways to shape metal at room temperature. But they are different. Cold forming is a general term for bending or stamping metal without heating it. Cold forging is a special type of cold forming.

In cold forging, metal is shaped by pressing it very hard between punches and dies. Both methods make the metal stronger. But cold forging makes stronger and more detailed parts. Cold forming makes simpler parts.

Clarify overlap and differences

Cold forging and cold forming are similar but applied in different situations.

Overlapping Aspects: Both processes are performed at room temperature. It preserves the strength of the material and saves energy.

Workpiece Shaping: Both involve pressure to shape the metal. In doing so, it becomes stronger without applying heat.

Key Differences:

Cold Forming: Cold forming includes bending, stamping, rolling, and swaging. Cold forming shapes the metal by compressing it, but it does not always use a die to achieve a precise shape. It produces simpler parts with it.

Cold Forging: Cold forging shapes metal by pressing it against a high-pressure die. It produces detailed and complex shapes. Punches, dies, and presses are used. It is used to make stronger and more complex parts.

Cold Forming is used to make simpler parts like wire, sheet metal, and tubes. It is used in electronics, construction, and domestic appliance industries.

Cold Forging hardens and makes parts more accurate. The parts must be strong, accurate, and identical in quality.

Cold Forming needs less pressure and no special tools. It needs fewer tools than cold forging.

Cold Forging needs greater pressure and special equipment. Like dies, punches, and presses to shape the metal. This hardens the parts.

Cold forging is a type of cold forming but yields parts more complex and precise. Cold forming yields simpler forms.

Include visual comparison

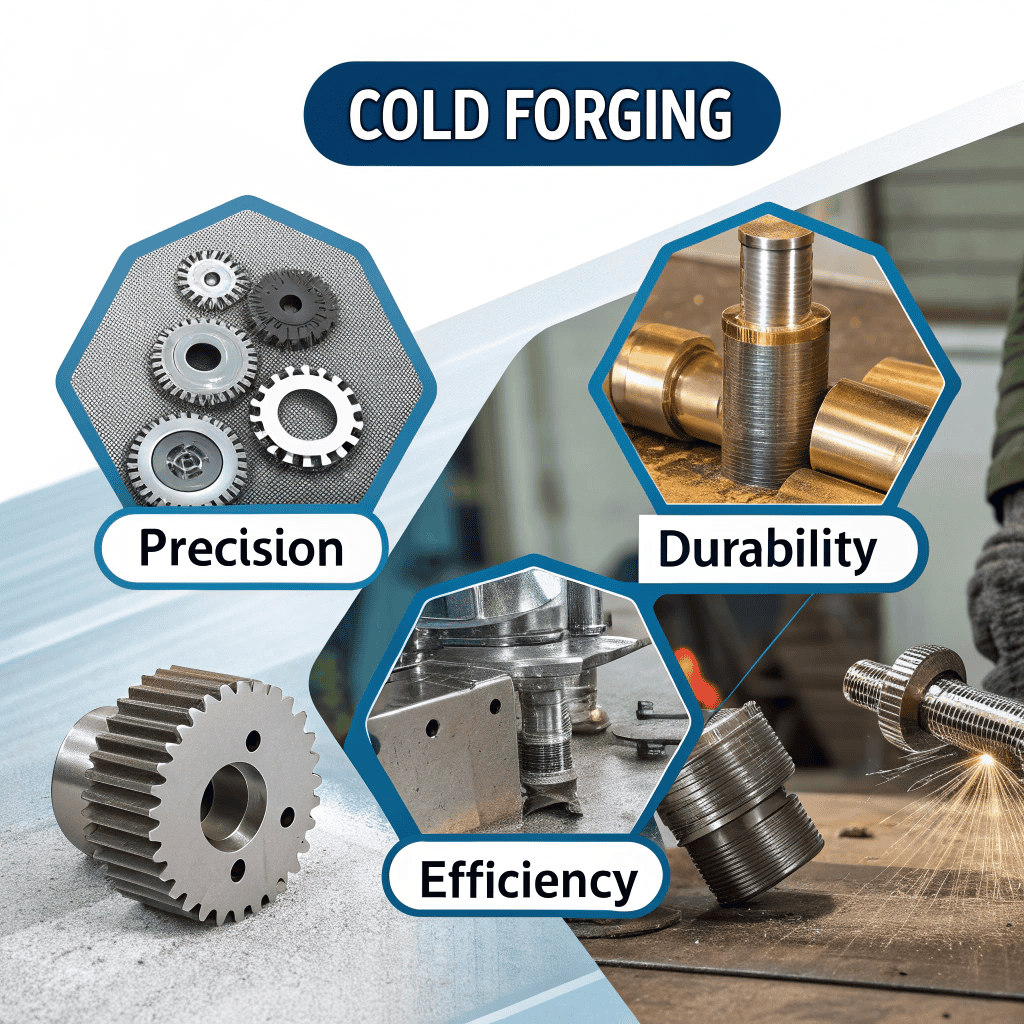

Advantages of Cold Forging

Cold forging is ideal to produce hard and low-cost parts in aircrafts and vehicles.

High dimensional accuracy: Cold forging makes parts extremely accurately. Thereby less extra work and waste.

Excellent surface finish: The process gives a smooth finish to parts, which is good when parts need little extra work.

Material savings: Cold forging uses almost the whole material, thereby less waste.

Improved mechanical properties: Cold forging makes parts harder and stronger, thereby longer lasting.

Limitations and Challenges

Though cold forging is very helpful, it has some problems:

- Tooling cost: The tools for cold forging are expensive.

- Material limitations: Some materials are too hard or brittle for cold forging.

- High equipment requirements: The tools and equipment needed for cold forging are expensive. So it’s ideal to make large quantities of parts.

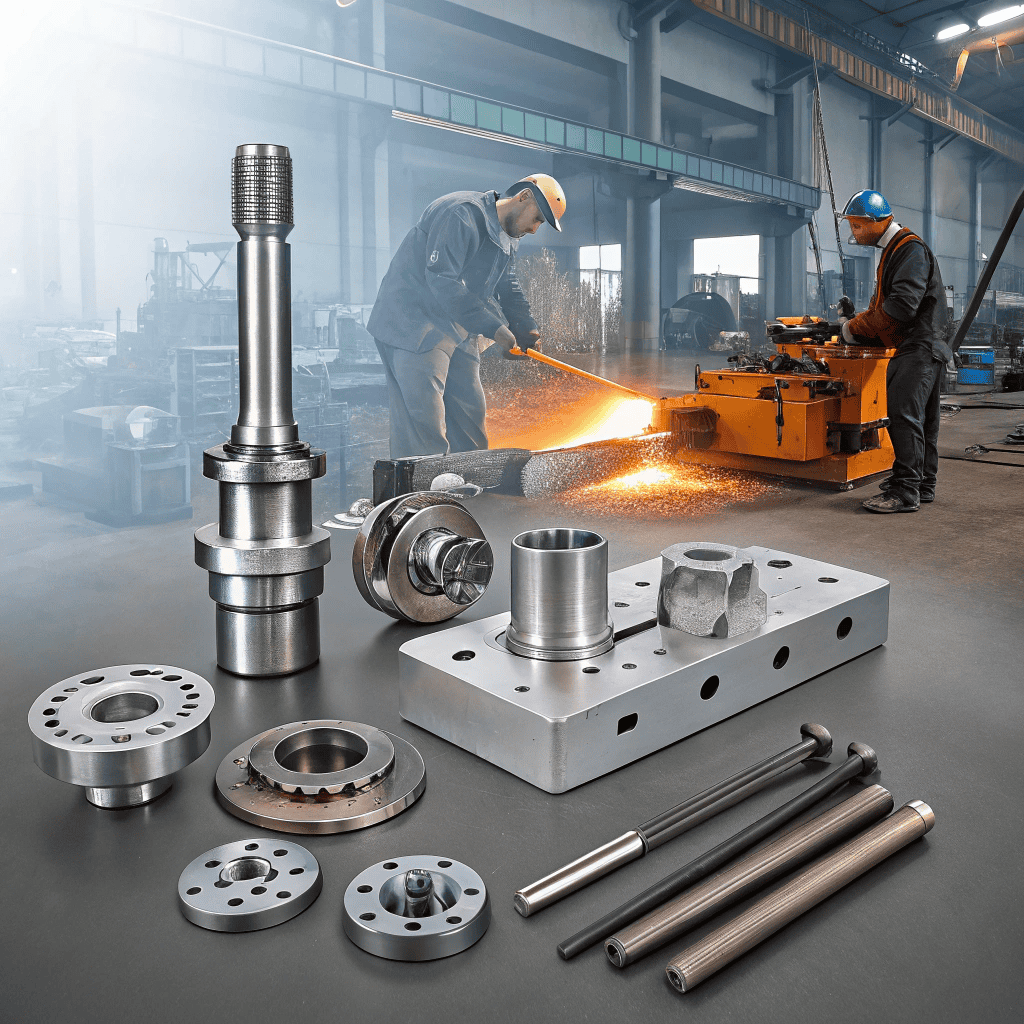

Cold Forging Applications

Cold forging is utilized in many industries to create strong and accurate pieces. Some of the examples are given below:

- Automotive Industry: Fasteners (bolts, nuts, screws), steering and suspension parts (tie rods, ball joints), engine components (connecting rods, crankshafts), transmission parts (gears, shafts), and brake system components (caliper bolts, pistons)..

- Aerospace Industry: Aircraft fasteners (rivets, bolts, pins), landing-gear components (struts, hinges), engine parts (turbine blades, compressor discs), and structural fittings and brackets.

- Electronic Industry: Electrical contacts and connectors, terminal pins, etc.

- Industrial Machines: Parts like shafts and bearings.

Conclusion Lines

Cold forging is a metal shaping process. It toughens parts, makes them accurate, and saves material. It is used by automobile, aviation, and electronics industries. Bolts, gears, and blades are typical components.

Cold forging is beneficial in that it generates parts that are stronger and have a better fit. However, it needs expensive tools and cannot be performed using any type of metal.

Hanke Construction Machinery Manufacturing Co., Ltd. makes cold forging parts just the way you want them. We are there for you whether you need durable parts for your machines or motor vehicles.

Contact us today and learn how we can assist you in making the finest parts for your applications!